Adopted into Manufacturing

Jeff Norgord, Marketing and Creative Director, Gardner Business Media, discusses his passion for all things design, advertising and manufacturing and how certain mediums were a precursor to his understanding of design that helped grow his fascination with the manufacturing industry. He wanted to learn how to create and build magazines. And that he did.

#design

Employee Spotlight

Jeff Norgord, Marketing and Creative Director

Gardner Business Media, Inc.

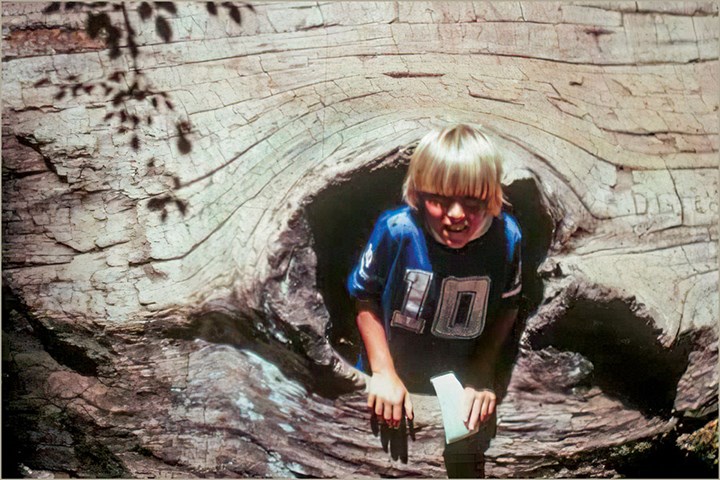

When it came to toys, I just wanted to explore, create and build my own shit. My adopted family encouraged the creative side in me with typical boyhood toys. These ‘make-your-own puzzle’ opportunities drove me into the weeds for days. Looking back today, I believe these mediums were a precursor to my understanding of design and helped grow my fascination with the manufacturing industry.

Truth, when it comes to toys, I never really enjoyed action figures nor embraced super-hero personas. Instead, I just wanted to explore, create and build my own shit. My adopted family encouraged the creative side in me with typical boyhood toys that included sandboxes, Tinker Toys, Hot Wheels, H.O. trains, electric race cars, Estes rockets, RC cars, model building and of course, Legos.

In conversations with several manufacturing professionals and some editors at GBM, many of us had similar experiences with these toys. They offer a dynamic means of connecting the dots with an accessible level of complexity. They are hands-on products, adaptable and deliver a ‘make-your-own puzzle’ opportunity that kept me into the weeds for days. Examining how they worked and how they were assembled (often by disassembling them), I enjoyed exploring connections between two dissimilar toys. Usually, I tried to create a conceptual mashup I could enjoy for a while and maybe even expand upon.

Looking back today, I believe these mediums were a precursor to my interest with design and helped grow a deeper fascination with the manufacturing industry.

Unwittingly and Headfirst

Another truth: I am a college drop out. In 1991, perhaps a bit blindly, I leaped into higher education to learn graphic design. Mind you, I had no prior ‘art training.’ My skill level with painting or drawing by hand was near zero. Still, my patient parents funded my desire to enter the ‘artist’s world’ for one specific reason: I wanted to learn how to create and build magazines.

Time, National Geographic, Sports Illustrated, even my dad’s home delivered industry rag aptly named Mining Engineering were continual curiosities for me. My naive thinking was simple: I like computers, colors, shapes, photos and words . . . just combine it all . . . that is all magazines are, right? The idea that college is where I'd learn how to design and build magazines was a bit misguided.

Along with the normal scope of elective classes, art history and the fundamental graphic design courses, I opted to sign up for ‘studio’ credits. In other words, the do-whatever-you-want classes to attain your degree — just pay us. I did this to teach myself the advancing realm of digital ‘applications’ driving graphic design. This is where the graphic design industry was rapidly trending however, the design professors at Utah State University were stuck in a decades-old model of hand-drawn art assembled by a low-tech paste-ups for class review. I did enjoy some of the hands-on work but digitally produced creative work was my more style. In contrast, the department professors considered digital a cheap and low-grade solution inside concept and execution. Further, digitally printed presentations were heavily frowned upon. After my first year of college, my graphic design professor left for sabbatical to learn the digital technologies transforming the next generation of graphic designers and the entire industry of content creators. That was a problem and I knew it.

To overcome the obvious educational shortfall and move closer to my intended career path, I camped out in the campus computer lab for hours. Flustrated (sic), I would explore and tune my design skills while learning design applications like Freehand, QuarkExpress and Photoshop. I ‘collected’ fonts and low-res images on 3.5-inch floppy discs. If you dug into my backpack, you would like find 80-100 of these unreliable devices inside a plastic three-ring binder. I’d spent countless hours drilling through graphic design books and industry annuals from Graphis, Communication Arts, Print and HOW. To some degree, these publications taught me magazine design but solely from a reader’s perspective.

They also heavily influenced and inherently schooled me on Good Design. Anchored by a decent concept, appropriate hierarchy, suitable type treatments and compelling imagery all coupled to a kick-ass headline, every article or advertisement could be tied together. The goal was always to connect, engage and inform the reader. Compelling and sometimes invisible design treatments will implore readers to stay in the advertisement or article and ultimately take more after reading. What I didn’t learn: exactly how magazines were produced. That would have to come later.

Meet the Specialists

Unlike the physical limitations of my childhood toys, the transformation of digital design technologies offered limitless geometric connections. Though no big deal today, I found it amazing how silly floppy discs containing shapes, words, fonts, colors and photographs would ‘magically’ convert my designs onto paper.

To achieve a finished tangible product, I met skilled people who worked on specialized machines which precisely converted my digital ideas into printed piece. This process required the expertise of photographers, pre-press bureaus, die-cutters, print shops, sign shops, paint shops and metal fabrication shops.

A door to the world of manufacturing had started to swing open. These specialized shops and knowledgeable people carried me into the complex world of retail products, consumer marketing and manufacturing at an industrial scale.

Graphic Design Meets Industrial Manufacturing

Having jumped out of the constraints of college coursework, I landed my first salaried job in 1994 designing sales collateral and packaging for a start-up called the Rocky Mountain Range Company. This was a portable propane outdoor stove line targeted at outfitters, tour guides and consumers. I collaborated with four other folks who were in different locations regionally. We worked remotely before the internet, email and mobile phones. We would meet in-person three or four times a month dealing with all the needs surrounding the design, manufacturing, marketing, distribution and sales.

Initially, we were looking at 24,000 fully assembled units for retail at big box stores like Sam’s Club, Costco, Canadian Tire and BJ's. It was an all-in effort. My work required the normal array of start-up needs that merged well with my existing and growing graphic design know-how: logos, product manuals and documentation, photo shoots, retail packaging, product labels and my first website.

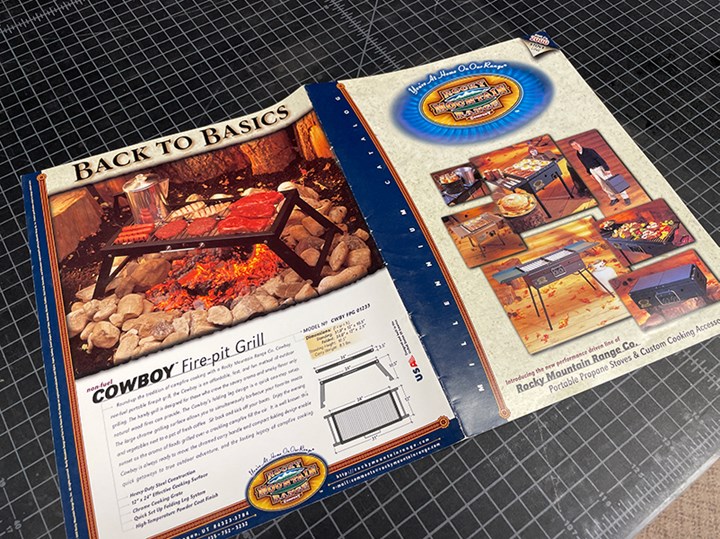

The front and back cover of the Rocky Mountain Range Company’s product brochure.

Photo Credit: Jeff Norgord

As a small team, we worked together to produce anything and everything necessary to get our product to market. One specific design request occasionally thrown my way was to illustrate discrete parts with mechanical specifications for production . . . without CAD. Yikes! To effectively do this, I also had to learn about more specialized manufacturing processes. The gravity of this pulled me into vertically focused manufacturing shops. This experience also taught me that my designs required ‘jigs and tooling.’ Ah-ha!

This spread represents the RMR Co. flagship outdoor stove products from their 2000 millennium catalog. These were aluminum prototypes that never made it into production. If you come across a BlackStone stove at a retailer, those are a derivative product stemming from the RMR Co. designs.

Photo Credit: Jeff Norgord

Ultimately, all the different technologies efforts would converge onto the manufacturing floor where the stoves were being assembled. Parts were sequenced along a long conveyor line paralleled by enormous boxes filled with small parts. Some of these boxes contained parts I had drawn and followed through the into the assembly line. Seamlessly, these parts were being accessed by people who diligently fastened components to build the final product: stove assemblies inside a retail box.

Through it all, I was exposed to custom tooling, mold making, injection molding, plastic pipe extrusion, metal stamping, milling and turning, water jet, powder coating, chrome plating shops, Thomas Register and CNC processes.

Things got a bit crazy both on the distribution and legal fronts. Ultimately the stove company was forced to fold in 1999.

Refocused on Branding, Design and Marketing

For a few years, my growing skill set allowed for an extension of independent design work. Called freelancing, this word is loaded with irony and the work can be too. Better terminology for freelancing might be ‘Don’tBother.’ The gig work was for niche businesses that included a rollercoaster manufacturer, an interior design firm and other small sole proprietorships. The local awareness of my efforts caught on and I was asked to partner with a boutique design firm called Digital Slant.

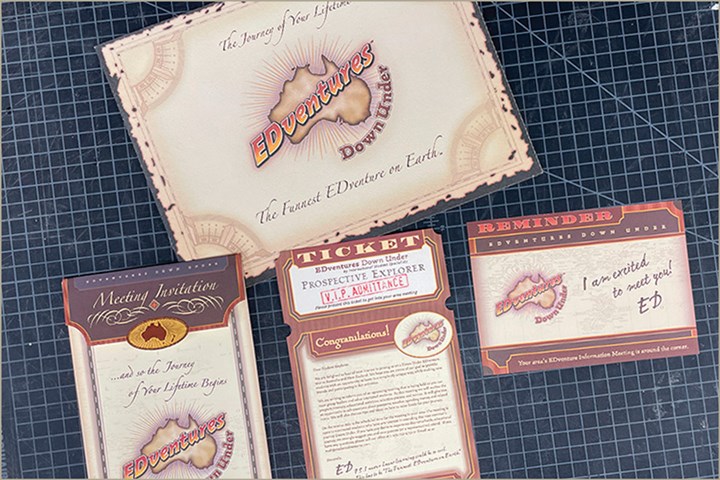

This client take-away was designed with a custom die-cut envelope, foil stamp logo and printed using metallic inks.

Photo Credit: Jeff Norgord

We landed clients across the spectrum of B2C and B2B services and industries. The work was inside typical hallmarks of a design agency: branding, logos, advertising, sales materials, billboards, photo shoots, illustrations, trade-show booth designs, website design and catalogs. Along with the normal efforts in printed collateral, we steered clients to incorporate more unique print production methods like custom die cuts, foil and blind embossing, custom envelope dies, large format printing, metal fabrication for signage and even custom sock designs. Again, for this customized work, my excitement and skill set grew while collaborating with specialized shops and uniquely skilled professionals.

Multi-piece promotional system. This consistent of a custom envelope and invitation, a follow-up post card and 12x9 sales brochure with pocket for additional materials.

Photo Credit: Jeff Norgord

Newspaper ads celebrating the 2002 Salt Lake City Winter Olympics sponsored by a local retailer.

Photo Credit: Jeff Norgord

Eventually, my love/hate relationship with Utah propelled me to move on. At the start of a nasty three-day snowstorm, I quit the agency and again leaped into the unknown. Hastily packing up all my computer gear and the start of my next portfolio, I commanded a U-Haul across the high plains of Wyoming to re-stage my design career in Denver, Colorado. Within a couple months, I stumbled into a full magazine workflow following another trend in design and manufacturing. Taking me back to the hands-on exploration closer to my childhood, this new creative endeavor was inside the scrapbooking industry.

Manufacturing a Magazine

By odd circumstance, directly across the street from my single-bedroom apartment, was a well-organized magazine workflow. It was for a consumer rag called Memory Makers. The year was 2002. Social media hadn’t yet become the dominant rabbit hole consuming the creatively-inclined homemakers and scrapbooking was all the rage.

Memory Makers fed into the trend. It had a circulation of 400,000+ and sold another 250,000 issues on newsstands. We produced 12 subscriber issues per year and added another three Special Interest Publications atop the normal year’s production schedule. This publication had recently been acquired by a Cincinnati-based company called F+W Media who also owned a property I knew already, PRINT and HOW magazines.

The Memory Makers workflow was held together by a deadline-driven editorial team of four writers beholden to a disciplined managing editor. There were three onsite account associates knocking down the display ad sales for a blossoming cottage industry of scrapbooking tool makers and manufacturers of paper goods.

The offices had two huge photo studios. Each studio had walls racked with 10-foot-high pallet shelving full of transparent plastic crates filled with props and paper crafting tools. These studios were insanely busy with staff photographers bouncing between two or three active sets per room. A director of photography was often followed by a freelance photographer who dealt with file management and the post-processing side of their photographic work.

The design team was comprised of five full-time editorial designers lead by a talented illustrator/art director. My girlfriend and I were kindly brought onto this design team in a full-time freelance capacity. We had much to learn from their process and they needed our contribution as the superman effect of the scrapbooking industry was growing magazine page counts. We didn’t know it at the time, but the industry was approaching a crescendo and Social Media would soon change the tide of revenue and success.

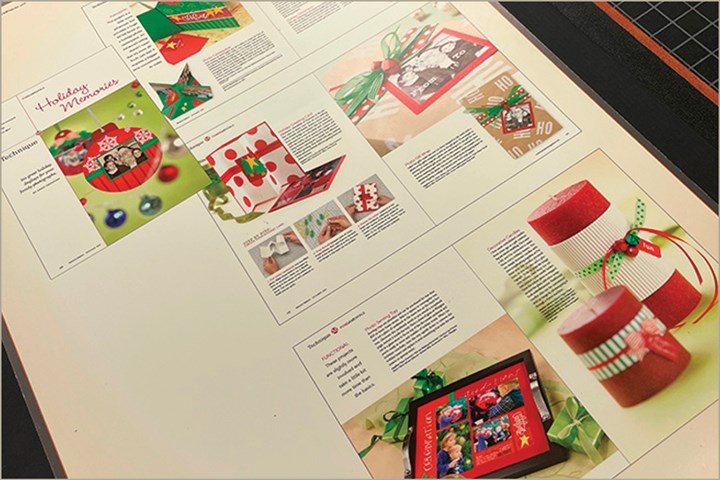

A Process Revealed

Following the editorial calendar, each issue’s production window was 16 weeks long. All the story boards started first with full page and fractional ad placements. Using pencil and paper, the art director would then rough out columns and feature layouts precisely allocating the real estate that would eventually weave the titles, body copy and imagery together. He then would pin those comps on one of six 4x8-ft cork boards assigning each designer various articles for photo studio work followed by design and layout. It was necessary given the huge volume of overlapping deadlines, editorial content and copy fitting tied directly to the design efforts. The shot lists were huge, in the range of 200-250 images per magazine. We often took a couple of days to capture hyper-critical conversations surrounding each cover. Given all the motions in producing each issue, we only missed one deadline by a day delivering each issue with a three-week gap between mail dates.

Technically, Memory Makers was way ahead of the curve inside a 'color critical' digital print production workflow. Since it was a consumer and newsstand magazine with plenty of competition, their value proposition to both readers and advertisers was quality, content and detail. The entire magazine’s pre-press system started in the photography studio and connected the camera’s files into Photoshop and InDesign. From there, each designer worked from a color-calibrated monitor massaging images and article layouts. The culmination of our work was delivered via PDF into a color-calibrated digital proofing printer. This workflow used a special ink jet paper that matched the magazine’s paper tone. If the inkjet paper was six or eight months old, we would give it away or recycle it. This whole process was set up, managed and synchronized by a large nationally-recognized web press printer. This workflow was insanely expensive to maintain, calibrated constantly and always finicky.

I finally found the complete magazine production workflow. The whole process incorporated the brand story, a collaborative team with specialized skills, a myriad of creative efforts, numerous technical moves and the money side of the story behind their printed products. Memory Makers also provided my first taste of the in-person events world and incorporated my creative efforts in designing promotional collateral, direct mail pieces, print advertisements and signage for the onsite experience. All told, building a magazine took far more than I could have imagined when I started college ten years earlier.

Pulling Back the Curtain

After a year of freelancing for F+W Media and Memory Makers magazine, they offered me a full-time seat art directing and designing another B2B magazine that served the textile and sewing industries. This transition was just in time too. A workflow consolidation of off-site publications was being called back to headquarters in Cincinnati. They offered me a transfer to HQ, which I accepted, however no one from the Denver offices followed. Yeah, those were a difficult few months hanging with the same team who had kindly taken me onboard and grew my skills inside their tight-knit workflow.

My new tasks in Cincinnati were to rebuild, design and adapt the old Memory Makers magazine production process with just five people. Clearly, it was time to move on from the magazine design and production efforts. Six months after my arrival, I transferred to F+W’s marketing department. During this time I found some small wins connecting on a redesign for PRINT magazine and getting to know editorial team from HOW. What a treat! Both of these properties influenced my early days learning design. Now I was judging contests and creating promotional collateral for HOW’s B2B reader conferences.

On the management front, there was a growing problem coming from corporate. F+W ownership had just turned over again to another VC followed by another team of ‘publishing’ suits from NYC. The design and creative work was starting to feel low-budget and constrained. Yes, I enjoyed the exposure and new opportunities, but the experience pulled away the curtain a bit, taking away some of the shine and awe. My concern was about staff who worked building the relevant content, engaging the loyal audiences and building brands. Instead, F+W’s strategy was to acquire and grow by debt-financing while slashing costs on their existing products. This tactic would, in part, ultimately undermine their own future and success (more about that here).

Final truth: when the walls start falling in, change seems to serendipitously reveal itself.

Meet a New Family

In December of 2007, on my way to London, UK, I crossed paths with a former F+W co-worker at the Cincinnati Airport. She mentioned her current employer, an established family-run B2B media company, was looking for a creative director. Further, she added their media products served markets focused on manufacturing. She asked if I would be interested in talking with them.

Without hesitation, I said, ‘sure.’

More than 13 years later and several decades beyond the toy mashups that occupied my youth, I’m still fascinated with all levels of creativity and now the world of industrial manufacturing. Graciously, GBM continues to be the perfect backdrop to encourage my creativity and professional contributions.

Need more information?

Jeff Norgord, Marketing and Creative Director

Gardner Business Media, Inc.

513-527-8879

LinkedIn

About the Author

Jeff Norgord

Jeff Norgord is Gardner Business Media’s Marketing and Creative Director. In addition to his day-to-day creative and marketing efforts, he will also jump behind the camera as GBM’s studio, event and field photographer. His passion for all things design, advertising and manufacturing continues at home in an immersive design studio and maker space. This is where Jeff’s creative energy pivots to building custom signage, commissioned artwork and furniture using a CNC router, Co2 laser and an industrial 3d printer.

He says some of his current influencers in the print domain are Communication Arts, Dwell and Metropolis magazines. In the digital domains, he follows a handful of Makers and DIYers that provide knowhow on machining, woodworking, photography, and home renovations. Occasionally breaking out of the media landscape, Jeff journeys back West to explore the mountains of Utah, Washington and Wyoming.

Originally from the state of Wyoming, Jeff has lived in numerous cities both large and small across the Western half of the U.S. He now calls Cincinnati, Ohio his hometown along with his endlessly patient partner Alyssa and a scaredy cat named Frodo.

RELATED CONTENT

-

AI Can Revolutionize Your Content Marketing

AI is taking content marketing by storm allowing you to build smarter strategies with content that’s more personalized than ever before. AI can influence everything from your graphic design to your email marketing campaigns and provide real-time reporting on your content performance. Leveraging AI is the smart move - let’s see how it’s done.

-

Infographic Design Trends for 2023

Looking for ways to make your visuals stand out in 2023? The team from Venngage has put together a new overview of key visual trends in infographics, and how you could look to present your data in the new year.

-

Inclusive Web Design with SEO Wins

Inclusive web design with SEO creates new opportunities for digital marketers and web designers. Website conversions depend on how well webpages assist people with decision making starting from search queries. Your role as an SEO is making webpages appear in search engine results at the precise moment for the exact people requesting them. Inclusive design opens up a world of possibilities to reach a greater target market. Avoiding an accessibility ADA lawsuit is driving companies to seek accessibility specialists. Many SEO consultants and agencies are adding inclusive design and accessibility to prevent the threat of a lawsuit and because their clients are investing in their branding and meeting competitive marketing challenges. SEO and inclusive design provide great opportunities for you in 2020.