VW Connects with Amazon and Siemens on Manufacturing

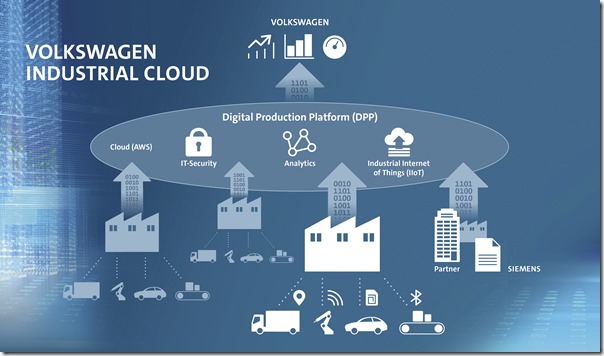

Amazon is increasing its penetration into the auto industry not just through things like Alexa and its multi-million-dollar investment in EV developer Rivian, but also with its Amazon Web Services (AWS), which will be used for its “Volkswagen Industrial Cloud,” which will combine the data from all of the machinery and equipment in the company’s 122 facilities.

#iot #hybrid

Amazon is increasing its penetration into the auto industry not just through things like the integration of Alexa into a variety of vehicles and its multi-million-dollar investment in electric vehicle developer Rivian, but also with its Amazon Web Services (AWS), which Volkswagen Group has announced will be used for its “Volkswagen Industrial Cloud,” which will, when fully launched, will combine the data from all of the machinery and equipment in the company’s 122 facilities.

(Image: Volkswagen)

According to Oliver Blume, Chairman of the Executive Board of Porsche AG and Member of the Board of Management of Volkswagen Aktiengesellschaft responsible for Production, “The Volkswagen Group, with its global expertise in automobile production, and Amazon Web Services, with its technological know-how, complement each other extraordinarily well. With our global industry platform we want to create a growing industrial ecosystem with transparency and efficiency bringing benefits to all concerned.”

One of the benefits of connecting all of the facilities into the cloud, according to VW, is that it will allow the standardization and networking of production planning and inventory management across the globe. This will lead to more efficient operations, as it will allow them to do things from optimizing machinery operations to eliminating supply bottle necks.

Supplier Integration

And on the subject of supply, the Industrial Cloud, which is being developed as an open platform, will allow the integration of the 1,500 suppliers and partner companies that work with the organization.

In addition to Amazon, Volkswagen is working with Siemens, which is the integration partner that is tasked with ensuring that the machinery and equipment at the 122 plants are efficiently networked in the cloud, and will work with Volkswagen in developing new functions and services that will then be made available to the suppliers of machinery and equipment.

“It will be possible to make production more efficient and flexible as well as further improving product quality.”

Explained Klaus Helmrich, Member of the Managing Board of Siemens AG, “We will network machinery, production systems and equipment more effectively using MindSphere and our automation platforms. This way, Volkswagen, suppliers and machinery producers will be able to leverage the potential of production data even more effectively. It will be possible to make production more efficient and flexible as well as further improving product quality.”

RELATED CONTENT

-

Sewing the Digital Thread

Within a decade, at least 50 billion machines will be linked in a vast Industrial Internet of Things, says Fred Thomas, automotive industry sector director for Dassault Systèmes.

-

Hacking Industry 4.0

The danger in Industrial Internet of Things technology is that data so conveniently shared can also be stolen or corrupted.

-

Bosch, SAP to Collaborate on Internet of Things

Robert Bosch GmbH and software developer SAP SE have agreed to work together on internet-connected systems for industrial equipment, tools, vehicles and other devices.

.jpg;width=70;height=70;mode=crop)