Tech Watch: Nov. 2018

Tiny Timepieces

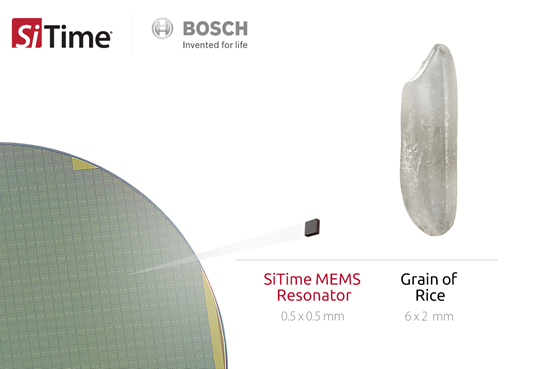

Bosch (bosch.us) and SiTime Corporation (sitime.com) announced a new strategic technology partnership to collaborate in micro-electro-mechanical systems. In doing so, the two companies distributed an image showing an SiTime-made MEMS (micro-electrotechnical systems) device (sized at 0.5 mm x 0.5 mm) dwarfed by a grain of rice (6 x 2 mm).

While small, MEMS will play an outsized role in managing batteries for machines connected to the Internet of Things (IoT) and powered by 5G networks, both of which come in handy for driver assistance systems, yet another MEMS destination. Another thing linking all of those technologies are resonator products, essentially sophisticated time pieces that SiTime designs. Bosch has already produced a billion such resonator machines for SiTime since 2009. But the next step in their partnership could easily outpace that output for the next-generation products.

"Over the next decade, the 5G, IoT, and automotive markets will drive the growth of the timing industry by creating a 200-billion unit opportunity,” said Rajesh Vashist, CEO of SiTime. “Automation, communications, and computing applications in these markets will require more features, higher accuracy and reliability from timing components."

Fig. 1 112018ADP-TechWatch-1.png

Bosch and SiTime announced a new strategic partnership to produce things like MEMs devices. Yes, these devices are small. Really small.

Voxeljet Offers Polymorphus Materials

Polypropylene is the reliable, do-it-all player of the polymer team. It’s literally good under pressure--e.g., the material doesn’t easily crack, and it can take the heat--making it ideal for housing electrical components. So it’s no secret that OEMs choose polypropylene when manufacturing bumpers, cladding, and other exterior trim components.

It’s noteworthy then that voxeljet (voxeljet.com) announced it will launch several new specialty materials for its sintering line of 3D printers, including a thermoplastic polyurethane and two polypropylene varieties.

“We are really excited about the speed we see in the qualification of new materials for our High Speed Sintering process, said Ingo Ederer, voxeljet’s CEO. “In less than nine months we were able to qualify various grades of polyamide powders and are successfully printing several types of thermoplastic polyurethane.”

Ederer said the company is successfully printing polyurethane on its smaller VX200 HSS systems and plans to roll it to its larger and automated production systems, including the VJET XHSS, at the end of 2019.

The thermoplastic polyurethane (TPU) is an elastomer that can be shaped into flexible objects while retaining high resolution, voxeljet noted. Some potential parts produced in this way include hydraulic seals and gaskets. Industrial parts.

“We believe these technology and material combinations have the potential to change our industries in the long-term,” Ederer said.

Radar Compacted

Consider the number of road variables one encounters when driving just a short distance, say ½ a mile, or so. Varying speed limits, traffic flow and vehicle variation, road construction, pedestrians, cyclists and--if you live in a city where they are now ubiquitous--app-rented electric scooters and the people who pilot them.

The goal of all driver assistance technologies is “intelligence”: the ability to read situations, determine which objects constitute threats (to the driver, or potentially from the driver) and make reasonably safe snap judgments. Managing all of that will require radar that responds “cognitively.” That means adapting things like channel selection, bandwidth and carrier frequency, as well as how long and how many measurements it takes in response to different conditions. The determining factor, is the length of the antenna array: the longer the array, the more accurate the reading. But there are knock-down effects. Longer arrays require more transmit and receive channels, and higher costs given the large volume of data that must be simultaneously processed.

Scientists at the Fraunhofer Institute for High Frequency Physics and Radar Techniques in Germany, also known as Fraunhofer FHR (fhr.fraunhofer.de/en.html), have been thinking about ways to deal with that data traffic jam. Its core research focuses on sensors for precise distance regulation and positioning as well as imaging systems. Scientists there have developed a Multiple Input Multiple Output (MIMO) radar that scans the scene, deploying complex algorithms to predict the radar target’s new position based on previous measurements. In this setup, the controller in the system selects only the specific receiver and transmitter channels it needs for the next measurement from the MIMO array’s 32 virtual channels.

This “one-step-ahead” predictive technology can accurately determine objects’ positions, even with a relatively small and cheaper system and lower real-time data volumes. This is how the radar system learns to continuously improve, the institute noted.

Fraunhofer FHR scientists presented their cognitive radar demonstrator at the European Microwave Week conference in September.

Luminescent Partnerships

If you have the pleasure watching someone use their fob to lock a 2019 Audi, well, you’ve quite possibly enjoyed a light show, compliments of the tail light signature. A pulsing set of 13 individual vertical light strips illuminate in sequence, not unlike a swift set of laser dominos setting themselves up and then falling down. A similar display happens with the headlights, as well as a slick array for the rear turn signals, which is more subdued. None of this illuminating pageantry is functionally necessary. It’s purely aesthetic, but distinctive aesthetics sell brands, particularly luxury brands.

All of this is to say that more individualistic lighting will be coming, much more. Magna Electronics (magna.com) and Rohinni LLC (rohinni.com) definitely are banking on that trend and have formed joint venture to produce ultra-thin micro LED lighting solutions. Those products, the companies say, will be brighter, lighter and more energy-efficient than alternative technologies, including OLEDs.

Magna Rohinni Automotive, based in Holly, Michigan, will be able to the bring micro and mini LED-based products to market faster thanks to the collaboration, the companies say. Using Rohinni's thin-film micro and mini LEDs, as well as a new co-developed technology, Magna Rohinni will be able to implant LEDs into smaller substrates, enabling more chttp://rohinni.comreative designs, according to the company. Translation: More lights in unexpected places and more creative designs.

"This joint venture with Rohinni brings thin, flexible lighting technology that mobility has not seen before," said Magna CTO Swamy Kotagiri. "Current automakers, new mobility companies, other lighting suppliers, and Magna's own product groups all stand to benefit from this collaboration."

Fig. 2 112018ADP-TechWatch-2.jpg

A Magna-Rohinni joint venture makes thin-film micro and mini LEDs, products the new firm says is available to increase the application of lighting in various parts of vehicles—even places where it might not be expected.