In today's manufacturing landscape, it's common to be tasked with doing more with less. You rely on a combination of factors to mold smaller parts with greater precision to satisfy growing demands and higher production levels — all within a smaller space.

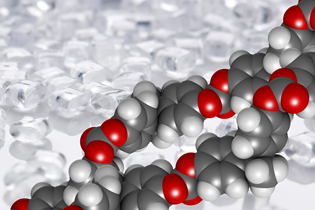

In this context, polycarbonate has become a popular material for modern products and injection molding applications. Manufacturers and designers increasingly select polycarbonate for its high impact resistance, stiffness, optical clarity, light weight and dimensional stability.

Because polycarbonate is an engineering resin, it requires more care and attention in processing than commodity resins. How are leading manufacturers leveraging polycarbonate and skill base to meet their production and business objectives?

Agenda:

- The properties that make polycarbonate an attractive choice for material selection

- Considerations for part design

- Best practices for processing equipment and functionality — from pellet to final part

- How to troubleshoot defects

- Case studies and examples of success using polycarbonate