Modern Apprenticeships for Automotive Technicians

Apprenticeship programs have proven benefits of developing in-house talent, closing the skills gap, and increasing profitability

#workforcedevelopment #labor

A good pipeline of highly skilled labor is essential to the auto industry. Automotive service technicians are an example of personnel who are in short supply. While we’ll use them as an example, the apprenticeship model is applicable to a wide variety of jobs within the industry.

The Skills Gap

The industry is facing some serious challenges. One, is the imminent retirement of long-term, highly skilled technicians of the Baby Boom era. And there are not enough young technicians entering the industry to meet demand. Another is the changing nature of the work, with hybrid and electric vehicles making up an ever-larger share of the market. Both current and new techs will need training in these technologies. And finally, a recent Carlisle & Co. survey shows dissatisfaction among the techs themselves, with more than one-third planning to leave their brand in the next year.

Modern Apprenticeship

Typically, auto businesses hire their skilled staff from a highly competitive labor market. But there is a different way.

As David Peterson, a principal at a Mercedes-Benz dealership, notes, "It became apparent that the answer [to the skills shortage] was a commonsense combination of a unique curriculum, a strong emphasis on life skills needed by someone launching a new career, and slow but methodical introduction of the new technician to the workplace...”

He's describing a tested method for developing bespoke, in-house talent in any business: the modern apprenticeship.

Apprenticeship has numerous, proven benefits. With apprenticeship, employers create their own talent, tailored to the precise skills the business needs. Apprentices work with experienced employee mentors, and acquire not only technical skills, but also an understanding of company culture – of how people communicate and how the business works. Research shows these “soft skills” are as vital to success as technical skills. And apprentices tend to stay with the companies who trained them.

Apprenticeships for automotive technicians are already in use and highly successful. I helped develop the Nissan Mentored Apprenticeship Program (NISSMAP) in Australia. The program’s mix of real‑world training, classroom study and one‑on‑one mentoring has helped Nissan Australia secure an industry‑leading apprentice retention rate of 82% (the national average is 49%).

One dealer in that program noted: “Within weeks of starting, apprentices could do oil changes and run basic diagnostics. We were able to charge for their time almost immediately. It overturned the perception that apprentices can’t contribute, from the get‑go, to the bottom line of their business.”

Major players in the U.S. auto industry are also running programs with the key features of apprenticeship. GM’s ASEP (automotive service education program) features paid, on-the-job learning in local dealerships; direct mentorship; and classroom time that leads to an Associate’s Degree. Since 1979, ASEP has produced over 17,000 automotive service technicians.

Making it Work

In recent years some governments have gone all in on apprenticeship. The US Federal Department of Labor’s Registered Apprenticeship Program (RAP) grew by 68.6% between 2013-2019, and since 2016, the federal government has made millions of dollars available to ramp up apprenticeships. Whilst this growth is impressive, lets never forget what drives apprenticeship. Rock solid employer engagement.

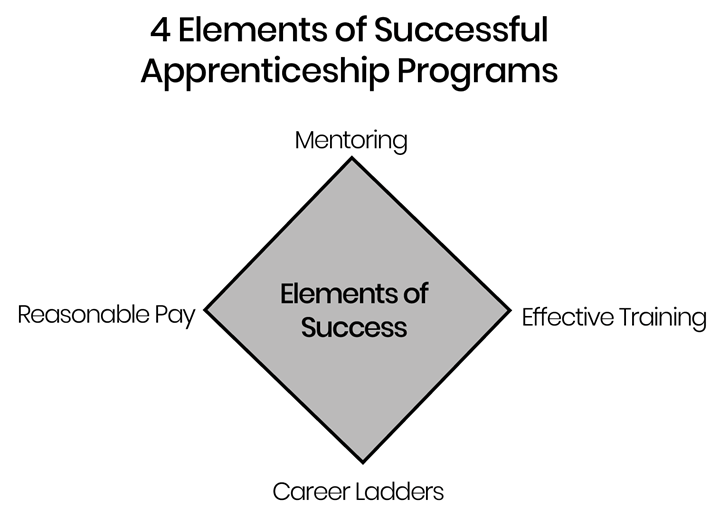

So where do you start? Successful apprenticeships are anchored by four key elements:

And to start your own apprenticeship, you’ll need to take on these fundamental tasks:

- Identify the apprentice-ready occupation

- Identify and engage an internal team; including people from direct service, middle management, and leadership, to formulate and implement the program

- Identify and engage external partners, including community colleges, high schools, civic and nonprofit organizations, state apprenticeship organizations, and others

- Identify mentors and coaches

- Outline candidate qualifications

- Identify achievable core competencies

- Create on-the-job training goals (performance measures) and related curricula

- Determine training and scalable wage schedules

- Establish marketing and recruitment strategies

- Develop ongoing evaluation processes based on feedback and outcome

If this seems overwhelming, it doesn’t need to be. You can dip into the federal and state resources and dollars for apprenticeship that are now widely available:

- Contact your state apprenticeship representative (states either belong to the broader Federal apprenticeship system, or they run their own State Apprenticeship Agencies)

- Find possible partners in your area

- Check out state tax credits and tuition support for apprenticeship.

With planning and commitment, you can use apprenticeship to secure your skilled workforce of the future and lock in profits for years to come.

Nicholas Wyman

Nicholas Wyman is CEO and Founder of the IWSI Group, a global network and leading enterprise dedicated to matching job seekers with automotive careers through apprenticeships. Over the last decade, the company has designed programs for BMW Australia and 'Nissmap' for the Nissan Motor company, as well as set up International scholarships where apprentices get to visit state of the art automotive dealerships such as Mercedes Benz of Louisville.

RELATED CONTENT

-

Bill Ford Describes Trump Meeting Over Mexico Jobs

Ford Motor Co. Chairman Bill Ford reveals he met with Republican presidential candidate Donald Trump a few months ago to discuss Trump’s “infuriating” comments about the company’s activities in Mexico.

-

Just In: Ed Welburn to Retire; Mike Simcoe Gets New Job

There are a lot of good people in the auto industry.

-

Creating the C-HR

Yes, this is a Toyota. A production crossover. One that will clearly appeal to those who are wondering where Scion has gone.