Ram 1500 Chassis Up Close

Just because it works hard doesn’t mean that it can’t be smooth, lighter and provide convenience.

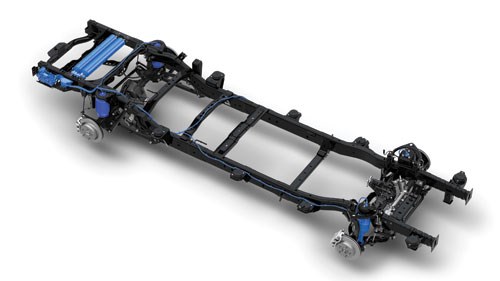

The 2013 Ram 1500 has a newly designed frame, which is certainly unusual for a vehicle that hasn’t undergone a full model change. There are two frame lengths: 120 and 140 in.

A focus on the redesigned frame was to reduce noise, vibration and harshness (NVH), while increasing stability and handling precision. As for the NVH, they’ve calculated that the improvement is as good as 30%, depending on the drive cycle. One of the ways that they’ve increased the stiffness of the vehicle—which contributes to the stability and handling they sought—was through the use of high-strength steel for the frame rails, which have a 20% increased yield strength compared with the previous generation truck’s rails. Another benefit for using advanced high-strength steel for the front frame section is that it allows a weight reduction of approximately 30 lb. without any diminution of strength or durability. Also, new, larger body mounts are used on the front frame rails (and at the C-pillar location), which helps improve NVH.

The side rails are fully boxed. Hydro-forming is used for portions of the frame in order to achieve dimensional accuracy: By hydroforming sections from a tube, which allows changes in both shape and cross section, they are able to reduce the amount of required welding, which means that dimensional distortions resulting from the welding process are minimized.

The Ram 1500 (as has been the case since the ’09 model) utilizes a multi-link, coil-rear suspension rather than a leaf-spring configuration, which is common on light trucks. Not only does this coil-spring design provide a smoother ride, but it weighs 40 lb. less than a comparable leaf-spring setup, and yet there is no reduction in performance. (Speaking of performance, the Ram 1500 offers a 11,500-lb. towing capacity and a 3,125-lb. payload capacity.)

Up front, there is a new independent suspension with redesigned upper control arms, aluminum lower control arms, and retuned geometry with coil springs. The ball joints on the front suspension are new; they are more durable than the ones they replace.

There is an available air suspension system that provides automatic load-leveling capability, increasing air pressure so that the truck has a normal ride height even though there is mass in the bed or the truck is towing. In addition to which, there are five height setting that can be manually or automatically selected, such as Park, which brings the vehicle down 2 in. from the Normal Ride Height (NRH) of 8.7 in. of clearance (measured from the base of the door sill), and Aero, which lowers the vehicle by 1.1 in. from NRH when the truck is driving at highway speeds. Additionally, the air suspension system allows changes in spring rates, with the springs being softened during Aero and made firmer when in Off-road 2 (which increases the clearance by 2 in. compared to NRH).

There is an electric power steering system. This has both performance and process benefits. The performance is improved because by using the electric motor to power the rack and pinion system rather than a hydraulic pump, fuel efficiency is improved by up to 1.8% and 5 hp is added (because power doesn’t have to be diverted to running the pump). As for the process benefits: all of the hoses and other apparatus associated with the hydraulic pump are eliminated, thereby making installation in the assembly plant simpler.

There is a braking system. They’ve relocated the ABS pump for improved NVH and engineered it for shorter brake pedal travel. Discs are standard on all models. The front rotors are 13.2 in. in diameter and there are dual-piston calibers; the rear rotors are 13.8 in. and are clamped with single-piston calipers.