Restart Checklist for Suppliers Developed and Available

Getting your operations back up and running in light of COVID-19 is daunting. This can help

#labor

If there is one thing that is certain about the effects that COVID-19 is having on the industry it is that there are a whole lot of issues that need to be addressed, particularly as companies are determining the ways and means to get back into production.

Inside FCA SHAP. FCA has announced that it plans to bring up most of its plants the week of May 18. Suppliers need to be ready. (Image: FCA)

While the timing seems to be nearly fluid, there is the solid fact that bringing back facilities under the conditions where the virus is still out there is not as simple (not easy: simple) as it otherwise might be: it is one thing if a plant goes down because of a strike or even a fire; the COVID-19 situation puts a whole new layer of things that have to be taken into account for restart.

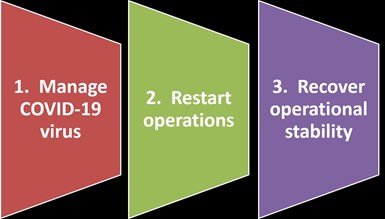

Key recovery steps. (Images: QAD/ Quistem)

To that end, and to help out the supplier community, Terry Onica, director of Automotive for QAD, and Cathy Fisher, president of Quistem, have developed an “Automotive Operational Restart Readiness” checklist.

Key drivers for the operational restart.

It highlights key operational areas, looking at the risks and the actions that need to be taken so that there is a higher level of confidence that workers are protected and customer product quality and delivery requirements are fulfilled.

Addressed in the checklist are:

- Contingency plans

- Inventory

- Immediate customer delivery requirements

- Immediate delivery plan, including transportation

- Supplier inventory and near-term delivery plan

- Availability of outsourced processes

- Temporary process changes

- Product/process re-qualification plan

- Accuracy of work instructions

- Workforce availability and training

- Equipment, tooling and gaging

- Facility infrastructure

- Communication plans.

If you’re interested in learning about this re-launch approach, you can learn what you need to know by going here.

Things are happening quickly. But you’ve got to get it right and this can help.

RELATED CONTENT

-

Marchionne Cancels Trip to Paris Auto Show

Fiat Chrysler Automobiles CEO Sergio Marchionne has cancelled a planned appearance at the Paris auto show on Thursday.

-

Young Auto Engineers Say Their Employers Don’t Measure Up

Only one-third of U.S. automotive engineers below the age of 36 agree that their work experience matches the way their employers’ portray themselves publicly, according to new research.

-

UPDATE: Unifor Ratifies GM Labor Pact by 86% Margin

Hourly workers at General Motors Co.’s CAMI assembly plant in Ingersoll, Ont., will vote today whether to accept an agreement to end a strike they began on Sept. 17.

.jpg;width=70;height=70;mode=crop)