Ford’s Project Apollo: Working With 3M and GE Healthcare for COVID-19 Response

Putting manufacturing engineering knowhow and clever design and product development in the battle against COVID-19

#labor

Jim Baumbick, vice president, Enterprise Product Line Management, Ford Motor Company, says that internally they’re calling it “Project Apollo,” referencing the Apollo 13 spaceflight when the astronauts and Mission Control had to bootstrap the systems of the command module and the lunar module after there was an oxygen tank explosion and they had to figure out how to get the astronauts home safely.

In this case, Ford is working with 3M and GE Healthcare to address the needs of healthcare workers, first responders and patients who are dealing with COVID-19.

Operators and assemblers assemble medical face shields. Ford Motor Company, in cooperation with the UAW, will assemble more than 100,000 critically needed plastic face shields to help medical professionals, factory workers and store clerks. (Images: Ford)

Baumbick also noted that the teams at Ford are collaborating with teams at General Motors so that there is a parallel approach being taken to fully leverage the know-how and resources of the auto industry.

Ford manufacturing engineers and other process experts are at 3M manufacturing sites in order to help identify the ways and means to increase throughput of the plants for things like masks and respirators.

“Power of Engineering”

As Mike Kesti, global technical director, 3M Personal Safety Div., put it, “Ford has unleashed its power of engineering. There are experts at our plants helping any way they can.”

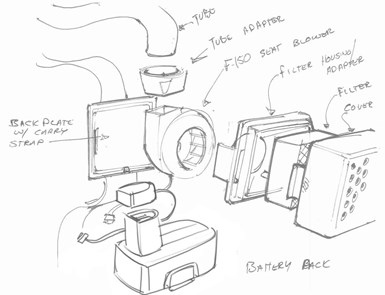

One of the things that 3M produces is a “Powered Air-Purifying Respirator” (PAPR), which is used by medical personnel and others: this is a portable device that blows clean air under a hood for extended time units.

Ford product engineers are, said Baumbick, working on a modified design that is simpler than the commercial product that 3M is building. For example, because they need a blower, they are considering using the climate control seat fan that is used for an F-150.

Because this needs to operate for extended periods, eight hours, they are looking at how they’d be able to use the battery supplies that are ordinarily used for power tools.

Bills-of-Material: Ideal and Practical

Baumbick said, “We thought about the basic design of the PAPR in its ideal state. Then we looked at the bill-of-materials and components to see how they line up with what we have. Without our assembly lines slowed or down we have access to key components and have different supply base channels.

Design of a “Powered Air-Purifying Respirator” (PAPR) that Ford is developing with 3M.

“Ford and the 3M team made a comparison of what is needed and are looking to leverage automotive-grade parts for a parallel system to the 3M design.”

Kesti said: “Ford has electronic components and blower units that can augment the existing supply chain and they are working to modify designs so that they can integrate the components and electronics.”

Simplifying Design

Similarly, Ford is working with GE Healthcare on developing a simplified version of the company’s existing ventilator.

Tom Westrick, vice president and chief quality officer, GE Healthcare, said “We have the clinical expertise and knowledge and have been making ventilators for a long time.” Ford is bringing to bear its design and manufacturing expertise, with its people learning the necessary requirements for medical-grade equipment.

Making Masks

Ford is also directly involved in getting transparent full-face shields into the field. The company’s design team has developed a shield of which 1,000 have been produced and will be going into test this week at Detroit Mercy, Henry Ford Health Systems and Detroit Medical Center Sinai-Grace Hospitals.

Adjustments are being made as required, and the company will be producing 100,000 face shields per week at its subsidiary Troy Design and Manufacturing’s facilities in Plymouth, Michigan.

Showing Up Strong

“This is the fabric of who we are,” Baumbick said. “All three companies. We see the need and we jump in and help.”

He added, “And our UAW partners are inspirational in the way they’ve shown up.”

Mike Kesti had three words to describe the teams: “Resourceful. Agile. Creative.”

Jim Baumbick had another: “Scrappy.”

RELATED CONTENT

-

On Developments at Lincoln, Magna, Fiskar, Volvo and More

Lincoln’s plans for electric; Magna and Fisker working together; Polestar in South Carolina; the Volvo XC60 driven; VW gets deep into 3D; Porsche exec on electric; BMW and hydrogen; Staubli cell for tire sensors; and Bridgestone invests in autonomous trucking company.

-

Things to Know About Cam Grinding

By James Gaffney, Product Engineer, Precision Grinding and Patrick D. Redington, Manager, Precision Grinding Business Unit, Norton Company (Worcester, MA)

-

On the Genesis GV80, Acura MDX, BMW iDrive and more

From Genesis to Lamborghini, from Bosch to Acura: new automotive developments.

.jpg;width=70;height=70;mode=crop)