Bosch's passive 3D technology; NDIR gas sensors

Bosch's passive 3D technology; Optimus Ride uses Velodyne’s lidar sensors in its entire fleet of self-driving vehicles; NDIR gas sensors; 3D Systems/Toyota Motorsport developing new 3D printers, materials and software.

Seeing and Believing

For a variety of reasons, 3D TVs and accompanying programs failed spectacularly in the home theater arena. But Bosch (bosch.com) sees a bigger future for three-dimensional imaging in the vehicle cockpit. This time, however, no glasses will be necessary.

Bosch is testing out three-dimensional dash displays that would put data animations front and center.

“Displays are increasingly becoming interactive systems that can better anticipate drivers’ individual needs,” says Steffen Berns, president of Bosch Car Multimedia. “The display’s depth of field means drivers can grasp important visual information faster, whether from an assistance system or a traffic-jam alert. Alerts that seem to jump out of the display are much more obvious and urgent.”

While Bosch did not set out timetables for specific features for 3D dash animations, the company did allude to features such as maps that give a sense of depth for more realistic navigation systems, improved spatial animation for rear-view monitors during parking, and infotainment functions, particularly for board autonomous or semi-autonomous vehicles in the future.

These alerts may command attention, but Bosch plans to deploy “passive 3D technology,” which performs the eye-grabbing functions without eye tracking or 3D glasses.

Displays, 3D or otherwise, may bring data to our eyes, but when it comes to the physical world around us, those eyes can be extremely unreliable. That’s the key point behind the another new Bosch development: the MPC3 mono video camera, which is presently launching on vehicles. Just because we see something on the road does not mean that we register and act upon it quickly. Bosch notes that in up to 50 percent of car crashes, drivers later report they had been looking in the correct direction, but still failed to “see” another car before an accident.

The MPC3 camera was developed with this lack of human visual perception/cognition in mind. The object recognition built into the camera makes use of AI in the form of the V3H chip, made by Renesas (renesas.com). The chip is calibrated to help the camera to detect if the edge of the road is passable, even when lane lines or other markings are absent. The camera also can be used to enhance legacy driver assistance systems and help expand their portfolio of applications, such as automatic emergency braking systems. It features optical character recognition that reads text and numbers on road signs, and presents this information to the driver on a dashboard display (perhaps in 3D on future versions).

“We want to make cars better drivers than people, and in this way to increase road safety. In other words, technology has to work more reliably than people," says the Bosch management board member Harald Kröger.

Optimus Rides with Velodyne

If you live in the right area, perhaps a smaller municipality or a closed campus, you may have seen a smallish bus-sized Optimus Ride (optimusride.com) self-driving vehicle roll by in testing mode. It soon will be equipped with lidar sensors supplied by Velodyne Lidar (velodynelidar.com) to help it pull actual passenger shuttle duty.

Optimus Ride will use Velodyne’s lidar sensors in its entire fleet of self-driving vehicles, which will operate at SAE Level 4. Those sensors, say the companies, will help Optimus Ride to precisely locate the position of people and objects around its vehicles, as well as calculate their speed and trajectory. With that information, the vehicle’s computer system will route it to its destination.

Optimus Ride plans to begin operating its relatively small fleet in four U.S. states. That includes Boston’s Seaport District and at the Brooklyn Navy Yard in Brooklyn, New York. The vehicles will also move in a commercial capacity at the Navy Yard to transport passengers between the NYC Ferry stop and the Cumberland Gate at Flushing Avenue, a key commuter hub. Optimus Ride will soon deploy at Paradise Valley Estates in Fairfield, California, and Brookfield Properties’ Halley Rise development in Reston, Virginia.

Going Meta

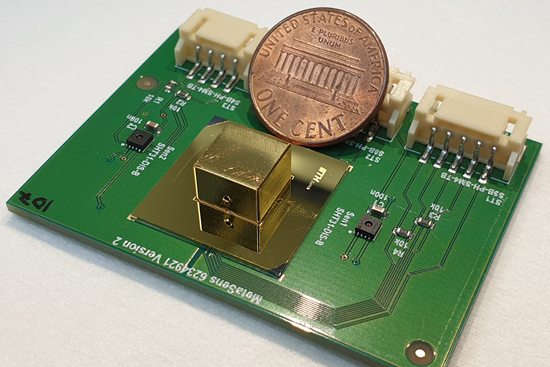

Scientists in Switzerland say they’ve engineered an infrared gas sensor with metamaterials that could potentially be used in vehicles, and is both smaller and has no moving parts.

Metamaterials are synthetic composites with properties that can’t be found in natural occurring metals or alloys, so they can, for example, do such things as altering waves of electromagnetic radiation or sound.

Researchers in Switzerland say they’ve engineered a metamaterial to develop a fully-integrated infrared (NDIR) gas sensor. With no moving parts, the sensor, which scientists say is among the smallest ever made, requires little energy to operate.

"Using metamaterials, we can omit one of the main cost drivers in NDIR gas sensors, the dielectric filter, and simultaneously reduce the size and energy consumption of the device," said Alexander Lochbaum from the Institute of Electromagnetic Fields of ETH Zurich, Switzerland and lead author on a paper detailing the process. "This makes the sensors viable for high-volume, low-cost markets such as automotive and consumer electronics."

NDIR sensors are used to assess carbon dioxide in exhaust, and different optical filters can be used to measure a wide range of other gases. While conventional NDIR sensors require light to pass through a chamber a few centimeters long to detect gas at very low concentrations, the newly designed sensor can do the same thing in a cavity about half a centimeter long.

Win on Sunday, 3D Print on Monday?

Lots of automotive suppliers buy 3D printers for in-house design, or they simply contract out work 3D printing firms through service agreements. It’s fairly rare to see an OEM subsidiary partner with an additive manufacturing firm to advance the technology itself.

That was, in essence, what 3D Systems (3dsystems.com) and Toyota Motorsport GmbH, a subsidiary of Toyota, recently announced. 3D Systems and Toyota Motorsport will develop “first-to-market manufacturing solutions,” which includes new 3D printers, materials and software.

“We see the unparalleled potential of combining 3D Systems' expertise and know-how with that of TMG to create technologies and define new additive manufacturing innovations in the automotive industry,” said Andreas Schambach, project general manager future production technology, TOYOTA Motorsport GmbH.