Reconciling a Minimalist Mindset While Marketing Manufacturing

Jodee McElfresh, Associate Digital Editor, Additive Manufacturing Media, Gardner Business Media, discusses how manufacturing impacts everyone, even minimalists.

Employee Spotlight Profile

Jodee McElfresh, Associate Digital Editor, Additive Manufacturing Media, Gardner Business Media

I think I’m a minimalist, but as I make notes for this column, it’s clear miser may be the more accurate term. Either way, parting with money, making space for stuff and being wasteful are things I avoid as if they’re an old classmate in the grocery store.

I still have and use my first canvas tote bag from 1990. My daughter who isn’t quite a year old looks great in my teenage nieces’ hand-me-down rompers and even in the sun hat with the colorful 80s pattern that I donned at her same age. My shoe collection does not extend much beyond brown shoes, black shoes, gym shoes and mowing shoes. I did buy a new spatula recently, but only to get every bit of peanut butter in the jar.

When I joined the Gardner team as digital editor for Additive Manufacturing Media, I felt a twinge of concern, wondering if my less-is-more preference would impact my work communicating about an industry premised on creating more things, including things that make more things.

That concern came from surface-level reflection. As I have learned about additive manufacturing and given more thought to that initial unease, I have found reason to believe that a minimalist mindset and manufacturing-related profession can be copacetic.

Less Is More in Additive

One of additive manufacturing’s (AM) claims to fame is complex geometries that meet a part’s needs often with less product input than conventional manufacturing. I am mesmerized by videos of a part being machined but feel almost physically ill watching chips fly away. I hear the cash register ding every time a chip falls and I wonder how many resources went into sourcing and preparing the material block. Fortunately, these chips aren’t always total losses as this article explains. Still, adding rather than subtracting allows a manufacturer to use an amount of material close to that of the product’s final composition, notwithstanding the necessity of sacrificial support structures and postprocessing. And AM has its own mesmerizing videos.

Manufacturing Meets Needs

When I think manufacturing, I often go straight to consumer goods and, more specifically, things that fall closer to want than need, but manufacturing covers the entire spectrum of want to need.

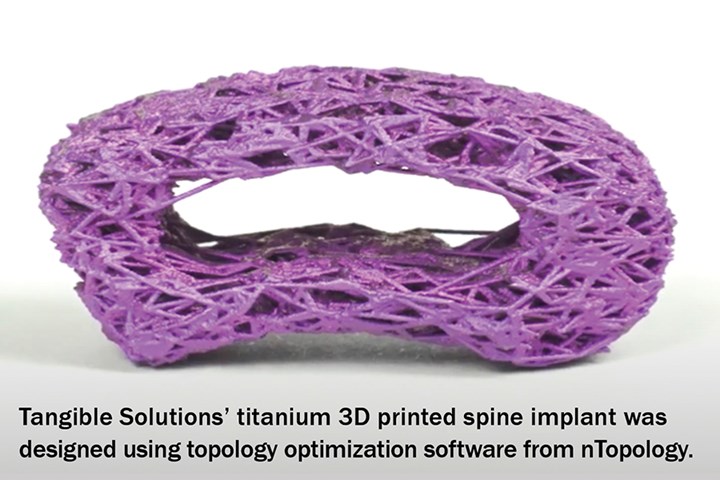

Medical devices that add time and value to one’s life are the result of manufacturing. Spine implants. Wheelchairs. Headgear. Dental pieces.

Getting from point A to B depends on manufacturing. Brake rotors. Micromobility vehicles. Shoes. Rocket engines?

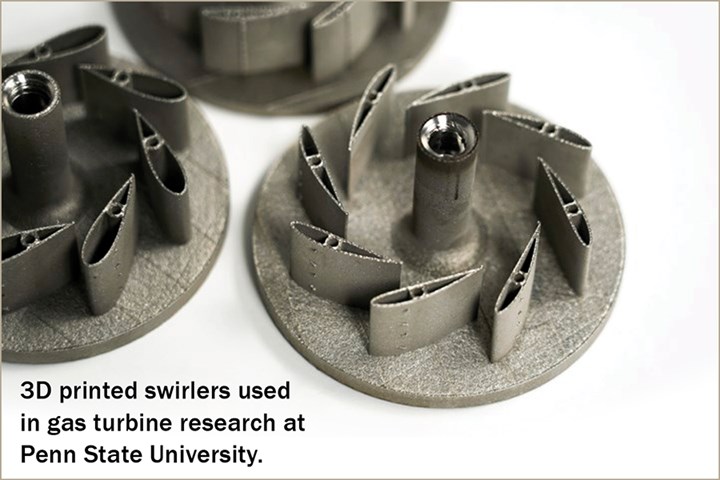

Power generation needs manufacturing (and vice versa). Fuel structures. Swirlers. Turbine blades.

Those examples feel more serious and possibly more justifiable for a miser geared toward a simple lifestyle. But even when an item doesn’t directly improve one’s wellness or move society and technology forward, I’m coming to appreciate the value of the value-adds. Why not have an attractive cupholder? Why not listen to your favorite composer on a speaker that catches every note from every instrument, rather than accept the distorted rendition from the cell phone you refuse to relinquish? (By you, I mean me here.)

It is nearly impossible to live a black-and-white life perfectly and perpetually saving all resources. That doesn’t mean it isn’t worth trying. There’s room for compromise thanks to manufacturers whose missions embrace resourcefulness. This sustainable approach to architecture is one. The same can be said for e-waste and metal scrap recyclers.

I have learned that the end game for innovation in manufacturing is not necessarily more stuff. Rather it can be finding ways to manufacture with less material, energy, time, stress, money and impact on marginalized communities, as well as producing items that are less of a resource burden in the long run.

While I will continue to save my First Communion money and wash my Ziploc bags, I will also continue to enjoy learning about the passion projects and advances that manufacturing, especially additive, brings to society. The beauty of innovation is that it is inherently endless. There will always be a new material, a new method and a new machine to be developed, and new needs to identify and address.

Additive Manufacturing Media has given me a new lens for looking at the tangibles in my life and introduced articles and videos that are helpful for industry insiders, but interesting and insightful to a manufacturing layperson like myself. I look forward to reading and watching them on my current phone for years to come.

Need more information?

Jodee McElfresh, Associate Digital Editor

Additive Manufacturing Media

Gardner Business Media, Inc.

513-527-8800 X7350

LinkedIn

Twitter

About the Author

Jodee McElfresh

Jodee McElfresh is the associate digital editor for Additive Manufacturing Media. She brings experience from the worlds of higher education, leadership development and mission advancement to the role. Her hobbies include successfully putting the baby, and then herself, to sleep. Past hobbies include indoor rock climbing, going for walks and practicing German.

RELATED CONTENT

-

In B2B Market Research, It’s About Quality, Not Quantity

Online market research tools offer a cost-effective way to gain insight into smaller B2B customer bases. In Part 1 of this 3-part blog, we covered the strategic underpinnings of market research for SMBs; the what and why. In part #2, we get down to the hows. Specifically, online survey best practices. Simple, well-defined questions can be deployed on a DIY basis. If more complex, a hybrid of DIY and professional assistance might be in order.

-

Brand vs. Product Advertising. What’s the Fuss?

Marketers have long debated the merits of brand vs. product advertising. In truth, there are reasons for both. The strategy depends on the marketing situation.

-

"Made in the USA" Podcast: Show for This Moment in U.S. Manufacturing

“Made in the USA,” is a six-part documentary-style podcast series that strives to uncover the hidden history of how manufacturing in the United States arrived at its current state and lays out where it can go from here.