Bentley Aims to Ground Rare Earth Metals

New e-axle matches the performance of current permanent magnet motors

By definition, rare earth metals are scarce.

Volkswagen Group’s Bentley luxury car unit aims to go a step further and completely eliminate them in its future electrified vehicles.

Magnetic Performance

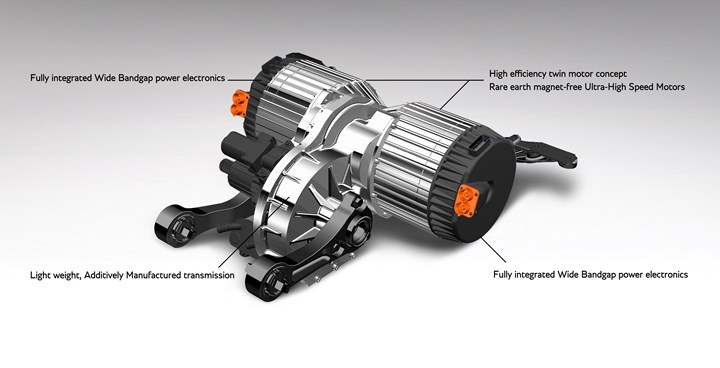

As part of a U.K. government-funded research program, Bentley is testing a prototype e-axle system said to match the performance of conventional permanent-magnet electric motors. The e-axle eliminates the use of rare earth elements and copper windings.

Bentley e-axle (Image: Bentley)

Rare earth metals such as neodymium, terbium and dysprosium are pricey and difficult to recycle. China currently accounts for about 90% of the world’s supply of the materials.

Following an initial 18-month investigation, Bentley and its partners are launching a 3-year program to further develop and study the technology. Dubbed OCTOPUS (Optimized Components, Test and simulatiOn toolkits for Powertrains which integrate Ultra high-speed motor Solutions), the study will focus on material and manufacturing process optimization.

Other members of the project include Advanced Electric Machines, FD Sims, Hieta Technologies, Talga Technologies, the University of Bath’s Institute for Advanced Automotive Propulsion Systems, and Nottingham University’s Thinking Pod Innovations unit.

What’s Next?

Bentley aims to introduce the technology on its first fully electric vehicle, which is due in 2026.

The carmaker already has committed to offer hybrid options for all future models, starting with the 2023 model year. Bentley’s first hybrid, a plug-in variant of the Bentayga SUV, bowed in 2018.