JLR Targets Increased Use of Recycled Aluminum

Putting materials back to work to help curb manufacturing emissions

#aluminum

Aluminum already is one of the most widely recycled materials in the world.

In fact, nearly 75% of all the aluminum ever produced in the U.S. and Europe still is in use today, Jaguar Land Rover says, citing data from the Aluminum Assn. This includes aluminum recycled from cars and trucks at the end of their lifecycles.

However, the carmaker notes, only a small amount of the aluminum content in new vehicles comes from recycled sources. JLR views this as an opportunity.

Closing the Loop

Currently, most aluminum from end-of-life vehicle scrap is re-used for low-end applications, such as beverage cans, bottle tops and foil food trays.

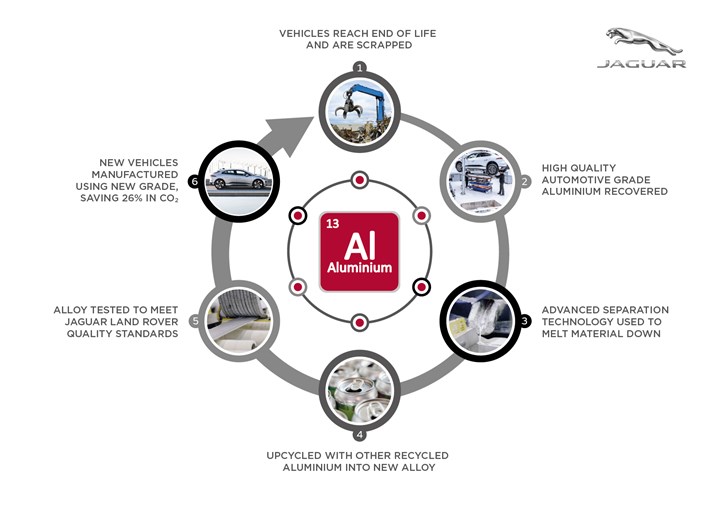

Closed loop process. Source: JLR

But JLR says new separation technologies allow aluminum car parts to be repurposed back into the automotive process. Under the REALITY Aluminum research program, the carmaker has demonstrated how recycled aluminum parts can be mixed with a lower amount of primary aluminum to form a prototype alloy with the comparable grade and quality of first-use material applications.

Benefits

Creating parts from recycled aluminum requires as little as 10% of the energy as that derived from raw material production.

As a result, JLR estimates that it can cut carbon dioxide emissions generated from the production of aluminum by 26%.

“This project has allowed us, for the first time, to recover premium automotive-grade aluminum from scrapped vehicles and re-use its unique properties,” says Gaelle Guillaume, JLR’s lead project manager for the REALITY initiative.

Progress

Half of the Jaguar XE’s body structure is made of aluminum alloy grades that contain a significant amount of recycled aluminum, according to the carmaker. The company boasts that, over the last six years, about 300,000 metric tons of recycled aluminum have been repurposed that way.

It’s all part of JLR’s Destination Zero initiative. As the name implies, the goal is to eventually eliminate all CO2 emissions from automotive applications.

Future shared and autonomous vehicle fleets could lend themselves well to recycled materials. JLR says such applications likely will have faster turnover rates and make it easier to plan bulk material strategies.

RELATED CONTENT

-

Karma from California

Chances are, you (like me) missed the 2017 U.S. Open Polo Championship broadcast.

-

Clean Factory in Stuttgart

One of the consequences of creating an electric vehicle, the Taycan, on Porsche goes well beyond the styling and performance of the vehicle itself.

-

Ford Introduces an All-New Expedition: It’s On for Big SUVs

The Ford Expedition—a full-size SUV if there ever was one—has been on the scene since model year 1997.