More Aluminum on Tap for Future Cars

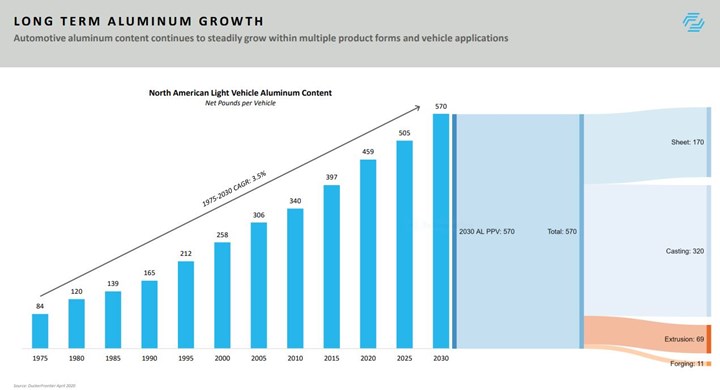

North American content per vehicle due to jump 24% by 2030

#aluminum

Carmakers have been using an increasing amount of aluminum in recent years to help keep vehicle weight in check as the size of new models continues to grow, due in large part to the industry switch from cars to SUV/crossover vehicles and pickup trucks.

2021 Ford Bronco (Image: Ford)

Since 2016, vehicles have added about 32 lbs of mass. During this time, aluminum content per vehicle has jumped by 62 lbs, according to a new report from DuckerFrontier. Recent wins include applications in the Jeep Gladiator and upcoming Ford Bronco.

And the trend is expected to continue through at least 2030.

More Closures

Aluminum content is projected to grow 12% to 514 lbs per vehicle (PPV) and 24% by 2030 to 570 PPV, according to the report, which was sponsored by the Aluminum Assn.

Source: DuckerFrontier

The authors attribute the growth to aluminum’s growing use in vehicle closures, body-in-white parts and chassis applications.

Lightweight closures are expected to continue to lead the way. Such components are expected to account for an additional 14 PPV of aluminum, growing from 59 lbs today to 73 lbs in 2026.

Doors represent the single highest net growth application of aluminum with penetration rates projected to jump from 21% today to 30% by 2026, according to the report. At that time, aluminum hood penetration is expected to reach 81% and liftgates/tailgates 44%.

EV Opportunities

New electric vehicle platforms also are expected to use generous amounts of aluminum sheet, extrusions, and castings for mass savings to achieve driving range targets, DuckerFrontier says.

“As electric vehicles become more widely available, greater aluminum use to extend range and help offset battery weight and cost will ensure consumers will still be able to choose high performing cars and trucks that are safe, fun to drive and better for the protection of the environment,” says Ganesh Panneer, chair of the Aluminum Transportation Group and vice president and general manager for Novelis North America.

One key application aluminum is vying for is battery cases. Novelis and other aluminum suppliers are developing modules that they say can provide weight and performance benefits over steel.

RELATED CONTENT

-

The Bollinger B1: An Electric Sport Ute

The Bollinger Motors B1 has been revealed.

-

Aluminum Sheet for EV Battery Enclosure

As the number of electric vehicles (EVs) is about to increase almost exponentially, aluminum supplier Novelis is preparing to provide customers with protective solutions

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.