I’m A Puzzle Guy

Looking back, Mark Albert now recognizes that some of his most satisfying moments as an editor revolved around the puzzle-solving aspects of writing an article. Putting an article together was much like the process of solving a puzzle, assembling a model kit, figuring out how to make something work or fixing it if it didn’t.

Employee Spotlight Profile

Mark Albert, Editor Emeritus, Modern Machine Shop

Here I am several years ago trying to figure out how to use this gizmo that demonstrates the arrangement of linear and rotary axes on a machine tool.

I like solving puzzles. This explains a lot about why I found writing articles for MMS enjoyable for nearly 40 years and why I continue to enjoy working part time in retirement.

That I am a “puzzle guy” is a recent realization. I discovered this trait just a few years ago when I started attending Game Night with my brother Greg, son-in-law Peter and other family members. Although I enjoyed playing board games such as Dead of Winter, Pandemic, Waterdeep or Diplomacy (we even played Candyland a couple of times for kicks and giggles), I didn’t seem to relish the experience as much as my brother and son-in-law. Sharing a car ride after the sessions, Greg was usually eager to analyze what made a particular board game especially clever and share his critique of the game’ production values (quality of diecut game pieces, artwork on the cards in the draw decks and so on). Plus he gave me a rundown of all the mistakes I made when it was my turn. However, we both admired Peter’s apparent enjoyment of reading the game rules closely to identify the tricks for following a winning strategy.

What was I missing? As Greg explained to me, “Peter and I are game-guys, that’s all. We love this stuff!”

Board games were fine, I thought, but I seemed to get more joy from working a crossword, doing a jigsaw puzzle or assembling an intricate model kit for my train layout than I did trying to outscore opponents for the number of zombies or warlocks I had vanquished. “Hey, I’m a puzzle guy!” I concluded.

Looking back, I now recognize that some of my most satisfying moments as an editor revolved around the puzzle-solving aspects of writing an article. Putting an article together was much like the process of solving a puzzle, assembling a model kit, figuring out how to make something work or fixing it if it didn’t.

First, you have to have a fairly clear idea in mind of what the puzzle will look like when solved. For example, the completed jigsaw puzzle will be a picture of roses in a silver vase. All the squares in the crossword will be filled in correctly. When assembled, the train station kit will look like a real train station. A well-written article will gratify the reader with a “good read,” which I imagined to be like riding a roller coaster, a series of compelling expectations followed by satisfying resolutions.

Next, you need to have the right pieces to work with. The 500 pieces of a 500-piece puzzle. A good vocabulary for crosswords. All the plastic parts in the model kit. For an article, you need a compelling main point that is significant, timely and insightful (what I like to call a “nuggety kernel”), plus of course, all the technical information to do justice to the topic.

Third, you need a general plan, or strategy for putting the pieces together. For example, do the straight edges of the jigsaw puzzle first, or sort the pieces by color. Scan the crossword to fill in the easy answers you know for sure. For the hobby project, decide which pieces should be glued together before painting them. For an article, my general plan is to follow a formula, which is essentially an expanded version of Mark Twain’s famous advice: “Tell ’em what you are going to tell ’em. Tell ’em. Then tell ’em what you told ’em.”

As you proceed, be sure to maintain the right attitude. You have to expect, even welcome, being temporarily confused, stumped or frustrated. Puzzles should be challenging enough not to be boring. Also you have to expect to be gratified, even exhilarated, when the right arrangement of pieces or words finally comes to mind. There will be trial and error. A lot of cutting and fitting may be needed to get the pieces together. Sentences may need to be rewritten many times to come out right.

You’re done when the outcome matches the clear idea you started with. The finished jigsaw puzzle will look exactly like the picture on the box lid. The train station model will look like its prototype on the B&O line. The feature article will give the reader an adequate thrill ride on the way to learning about the best way to apply some new metalworking technology.

Being an editor included many seemingly glamorous moments. Visits to new and interesting places around the country and the world. The electric buzz of a big tradeshow, IMTS in particular. Meeting people with great new ideas about innovations in our field. To me, though, all of these activities were subordinate to the task of writing feature articles, monthly columns, tech reports or whatever writing project was assigned to me.

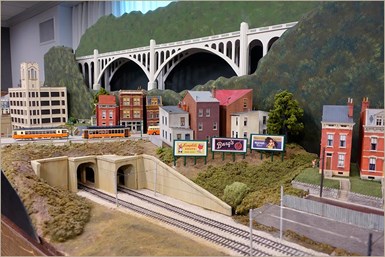

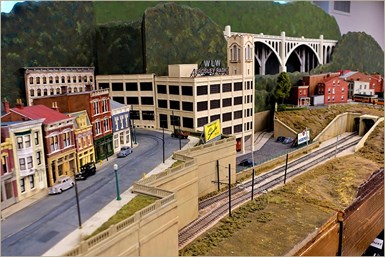

Mark's main hobby is constructing a model trolley layout, shown above and below on display at a regional model railroad convention a few years ago. He says writing an article or building something for his layout share many of the same puzzle-solving challenges.

This overriding task of writing, writing, writing became clear to me not long after I joined the staff of MMS in January, 1980. I quickly learned that producing strong content was the core of the writing editor’s job.

By the time the company moved to Clough Pike in 1983, the process of writing was no longer quite so intimidating. I was getting pretty good at using my puzzle-solving skills to get articles into the shape I envisioned. I also had a workable understanding of metalworking technology by then. With word processing now available, I readily could capture the right pattern for the ideas I wanted an article to express.

Over the years, there would be many “ah-ha” moments while I was piecing together the intricacies of electrical discharge machining, figuring out the function of CNC postprocessors, grasping what makes a properly formulated metalworking coolant effective and so on. With every new editorial puzzle solved, the next one became a little easier, and a little more enjoyable.

When we moved to Valley Avenue in Newtown in 1997, writing, editing and publishing had become largely digital. Putting words, illustrations, full pages and entire issues together was a streamlined, integrated process. It was certainly quicker and easier to make the pieces fit.

The next 20 years or so were blessedly more of the same. Always new advances in metalworking and more automation to figure out. I was especially intrigued by the “puzzles” encountered in emerging standards necessary for data-driven manufacturing. What does an MTConnect adapter or agent do? Why must cutting tool companies put product data in a certain XML format? How can a manufacturer keep track of every single part forever with a UUID? Where are we headed with the digital thread concept? All of these puzzles and many more became topics for articles I was particularly proud of. I love this stuff!

Working puzzles like this can be addictive. Perhaps that is why I did not want to let it go entirely after retiring.

About the Author

Mark Albert

Mark Albert retired from the staff of Modern Machine Shop in January, 2019. As Editor Emeritus, he continues to write feature articles and other pieces as assigned for MMS. His first article for Products Finishing appears in the February 2021 issue (a version of this article tailored to the MMS audience will appear later in 2021).

Mark joined the MMS staff in January, 1980, after a three-year stint with the Social Security Administration, his first job upon completion of a M.A. in English from Indiana University (Bloomington). He has a B.A. in English from the University of Cincinnati.

RELATED CONTENT

-

Post-COVID Considerations for B2B Marketers

While we begin to return to “normal” from COVID-19, there are lessons for B2B marketers to learn and actions to take to recover and grow business as a result of this experience. Change is in order in how we look at B2B marketing, and our customers, in the near term “post-COVIDian” future. Call it a commonsense approach, rooted in proven best practices, our new-found “pull together” mentality and need to adapt to change. Not a blueprint, just parts and pieces to frame thinking. Sum it up in 5 words: Consistency; Community; Integrity; Agility; Contingency.

-

Shifting Landscape of Technology Is a Never-Ending Education

Brent Donaldson, Senior Editor, Modern Machine Shop and Additive Manufacturing Magazine discusses how the shifting landscape of technology that all of Gardner’s writers and editors cover is a never-ending education. If we are truly doing our jobs, we will never feel like we’ve mastered them. As I continue writing and reporting for AM and MMS, it’s easy to imagine how these technologies’ interdependency will continue to grow. It also seems clear that this kind of reporting — the kind that requires editors to experience and share new manufacturing technologies and strategies — is the kind of reporting that only Gardner can produce with any depth. I’m grateful to be part of it.

-

Securing Career at Gardner Business Media—A Dream Come True

Eduardo Tovar, Editor-in-Chief, Modern Machine Shop Mexico discusses his dream come true of securing a job at Gardner Business Media. After hard work visiting associations, suppliers and key contacts in Mexico, a good readership was built and three key employees in sales, marketing and audience development were hired. Today, the team has 18 employees and Modern Machine Shop Mexico is the top magazine in Mexico in the metalworking and manufacturing sector.