Inside Xpeng Motors

A look at some of the technologies being deployed in a new factory building electric vehicles in Zhaoqing, Guandong Province

#hybrid #robotics

The Zhoping Xpeng Motors Intelligent Industrial Park was 15 months in the making, and on May 19, 2020, the factory obtained the official production license from the China Ministry of Industry and Information Technology to put the Xpeng P7, an electric sedan, into production.

Xpeng P7 electric vehicle. (All images: Xpeng)

The vehicle production area for the manufacture of the EVs is 1 million square meters (going to 2 million) and consists of five workshops: Stamping, Welding, Painting, Final Assembly, and Battery Pack production.

The Industry 4.0-compliant plant staff includes 600 personnel. Of the engineers there, 74% have 5+ years’ experience and 78% joined from other OEMs.

He Xiaopeng, Chairman and CEO of Xpeng Motors, said, “We are a firm believer that manufacturing is the foundation of smart cars. Only when you build solid powertrain and vehicle hardware, can you differentiate with data operation, autonomous driving and connectivity software.”

Stamping

- 100% automated

- Features a 6,600-ton stamping line

- Produces up to 12 pieces per minute

- Parts produced with a precision of 0.1 mm

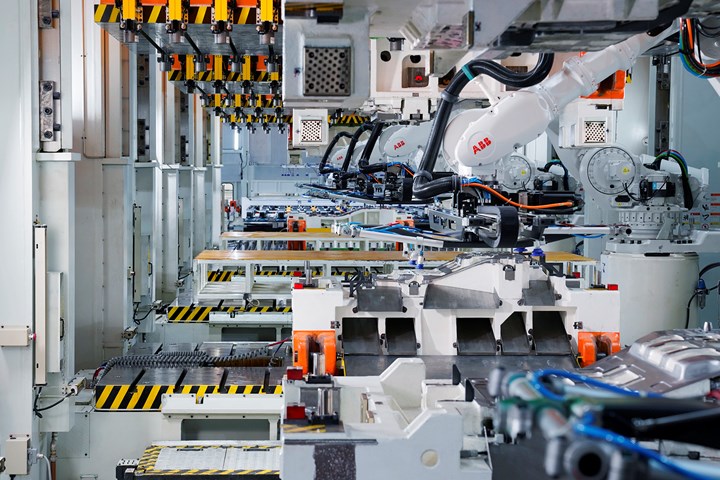

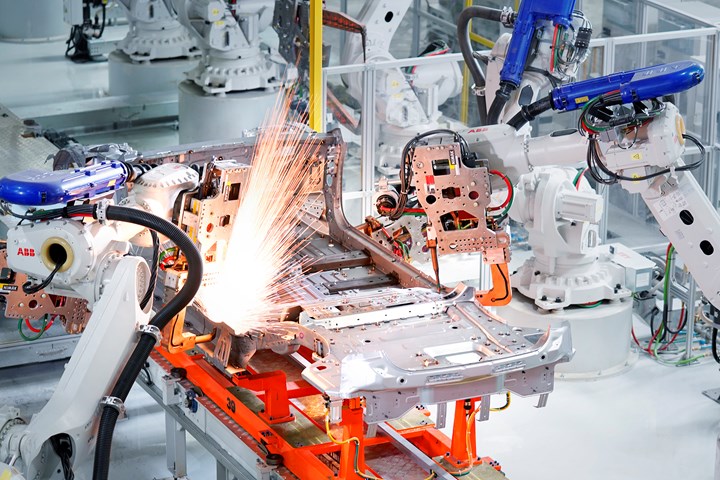

Welding

- Equipped with 210 ABB industrial robots (there are a total of 264 robots throughout the manufacturing complex)

- In addition to welding, gluing and aluminum plate riveting are performed

- Vehicle bodies are steel and aluminum

- Welding machines are adaptive to provide as much as 30% energy savings

Painting

- Thin-film pretreatment and cathode electrophoretic tech reduces wastewater discharge, slag yield (down 94%), energy consumption (down 25%)

- Zero heavy metal emissions

- Uses BASF high-throwing powder coat and B1B2+2K water-based varnish, double-layer paint

Assembly

- Highly automated with AGVs and robots

- Digital system assures all fasteners have the proper torque

Battery Pack

- AGV-based production line

- Robotic assembly

- Each battery pack undergoes 198 offline tests and 89 performance tests

RELATED CONTENT

-

Choosing the Right Fasteners for Automotive

PennEngineering makes hundreds of different fasteners for the automotive industry with standard and custom products as well as automated assembly solutions. Discover how they’re used and how to select the right one. (Sponsored Content)

-

On Zeekr, the Price of EVs, and Lighting Design

About Zeekr, failure, the price of EVs, lighting design, and the exceedingly attractive Karma

-

GM Seeks to Avert U.S. Plant Shutdowns Linked to Supplier Bankruptcy

General Motors Co. says it hopes to claim equipment and inventory from a bankrupt interior trim supplier to avoid being forced to idle all 19 of its U.S. assembly plants.

.jpg;width=70;height=70;mode=crop)