on Building the Honda Pilot, the F-150 Lightning, an e-bike from Wham-O, & solid-state batteries simplified

Building the 2023 Honda Pilot. . .the F-150 Lightning considered. . .check out the Model Y manufacturing video. . .Wham-O (yes, Wham-O) has an electric bike. . .solid-state batteries explained

Producing the 2023 Honda Pilot

The 2023 Honda Pilot in the Alabama Assembly Plant. (Image: Honda)

One of the most important vehicles in the Honda lineup is the Pilot, the three-row midsize crossover. The first-generation was launched in 2002 as a 2003 model year vehicle. The fourth generation went into production two weeks ago, December 15, at the Honda Alabama Auto Plant (AAP), which is the exclusive source of Honda’s biggest SUV. And for this fourth gen, the vehicle was moved onto Honda’s new light truck architecture (which it shares with the Acura MDX); this necessitated more changes in the factory than any model built at AAP had required.

To get a sense of the changes in the plant we talked with Katherine Avants, manufacturing project leader for the 2023 Pilot.

Avants says that she has worked on model development for the Pilot for about six years and platform development for a couple years prior to that.

Reset

However, during the model development they took a pause to “reset targets” for the vehicle. “The North American market was changing, and we wanted to focus on the right things,” she says. “We used the time to reset the design.”

Keep in mind that since the third generation launched in May 2016, there have been new entries to the segment, including the Hyundai Palisade, Kia Telluride and Subaru Ascent, and the venerable two-row Jeep Grand Cherokee added a third row (the “L” model). So the competitive landscape changed significantly, which the Honda development team had to take into account.

Process

One change that impacted manufacturing operations was a switch to a large panoramic roof. Avants says that the previous generation model’s moonroff was installed with automation. But to order to accommodate the new, larger roof, it would have been necessary for an expensive modification in terms of required equipment.

A process engineer started thinking about how things are done in assembly when the robots are down and it is necessary for associates to perform the tasks. She then realized that there is a way to perform the installation manually using automated tools for such things as lifting the roof in place and fastening it, but doing so in a way that would take the well being of the associate into account and meeting the line rate requirements.

Ergo

One of the things that they paid careful attention to in preparing the plant to build the ’23 Pilot was ergonomics. So, for example, they adopted what Honda Manufacturing calls the “front-end module,” an approach used in other Honda plants but not AAP until now.

Avants explains in the previous setup, if someone needed to install components in the engine area it was necessary to reach over the bulkhead. Now the associate can step into the area and work directly without stretching or bending.

The front end modules are assembled on a subassembly line, then brought to the main line where they are bolted to the front of the vehicles.

Sheetmetal

And while in that vicinity, Avants points out: “The hood is gigantic.” It is so big it exceeds the material coil width. The have to rotate the metal 90° from the ordinary orientation.

“The doors are huge,” she says, then explains that they have to use a secondary shear process in stamping, then splice the pieces together and use laser welding to join them.

She says that there are numerous changes in the plant for the new vehicle. They’ve added new robots, including those that are used for body transfer in place of the transfer lifts that are ordinarily used.

Nonstop

One of the most remarkable things—although a way things are done at Honda manufacturing plants—is that going from the third generation to the fourth didn’t necessitate a plant shutdown.

“There were a couple gaps in assembly from the old Pilot to the new,” Avants says matter-of-factly.

Amazing, we think.

///

2023 Ford F-150 Lightning Lariat 4x4

The F-150 Lightning. An electric truck that is based on the best-selling truck model. (Image: Ford)

Prior to voting for the 2023 North American Car, Truck and Utility of the Year (NACTOY) winners, I had the time to spend some time in the Ford F-150 Lightning, a Lariat 4x4 SuperCrew, one of the three finalists for the award that will be announced on January 11, 2023.

To go out on a limb—a limb the width of a giant sequoia’s trunk—the Lightning will take the Ed Welburn-designed trophy for its category. (As today is roughly two weeks before the announcement, I could be wrong. But. . . .) Ford has taken the truck that is fundamentally its franchise and turned it into something different while keeping many of the characteristics that make it what it is.

It is quite a remarkable vehicle.

The NACTOY awards are predicated on factors including innovation, design, safety, handling, driver satisfaction, and value.

Innovative

There are several ways to look at the Lightning from the perspective of innovation. One thing that has really caught the attention and imagination of many is the “frunk”: pop the hood and find 14.1 cubic feet of cargo capacity, cargo that can range from work materials to iced beverages (yes, the melted ice can be readily drained).

There is the simple fact that Ford engineers transformed a vehicle that had a conventional powertrain to one deploying two electric motors that produce 452 or 580 hp, depending on whether the truck is fitted with the standard (98 kWh) or extended-range (131 kWh), liquid-cooled lithium-ion battery.

While it might seem as though they would have to compromise in making that switch, if they did it surely isn’t evident. (Yes, there are differences like range—the standard Lightning setup provides a range of 240 miles, and were you to get a gasoline-powered F-150 with a 5.0-liter V8 and a 23-gallon fuel tank (the biggest engine and the biggest tank on offer), even though its EPA combined miles per gallon number is just 19, that still means 437 miles of range. The Lariat and XLT models, which have the extended battery, have 320 miles of range and the top-of-the-line Platinum 300 miles.)

Seamless

While the Lightning is based on the F-150 and so, no surprise, looks like an F-150, there are modifications to the truck exterior design to facilitate its performance as an electric vehicle. Aero matters. There are the obvious wheels that are largely closed. There are more subtle changes such as the rear taillamp housings (which really are something that could be overlooked but ought not be because they’re well designed and executed).

And while it looks like a standard F-150, it doesn’t sound like one: While at the window of a drive-thru restaurant the employee asked if it was the Lightning: “It’s so quiet!” he exclaimed.)

Safety Tech

Safety takes the form of the standard Ford Co-Pilot360 technologies that are standard across the lineups. The base 2.0 package includes Pre-Collision Assist with Automatic Emergency Braking (includes Pedestrian Detection, Forward Collision Warning and Dynamic Brake Support), BLIS with Cross-Traffic Alert, Lane-Keeping System (includes Lane-Keeping Alert, Lane-Keeping Aid and Driver Alert), Rear View Camera, Auto High Beam headlamps, Reverse Sensing System, Reverse Brake Assist and Post-Collision Braking. Then there’s Assist 2.0, which adds Intelligent Adaptive Cruise Control with Stop-and-Go, Lane Centering and Speed Sign Recognition, Evasive Steering Assist, Intersection Assist, Connected Built-In Navigation (3-year trial).

And optional on Lariat and standard on Platinum one can get Active 2.0, which adds Ford BlueCruise, Active Park Assist 2.0 and Phone As A Key (which isn’t exactly safety, but it is a feature). And given that this is predicated on the F-150, the robustness of the structure helps with safety, as well as all of the technology that Ford has brought to bear on the truck.

As for handling, the front suspension is independent double-wishbone with coil-over shocks and the rear is independent semi trailing arms with coil springs. It rides well (the batteries help provide a lower center of gravity), but let’s not get carried away: this is a pickup, not a Ford GT.

While not “handling” per se, the throttle response is most impressive.

Whether one is satisfied with the truck is something that can be determined only after a period of time living with it. But it is clear that the build quality and the amenities offered are certainly top-notch, so odds are there is going to be that.

Value Equation

And then the value, which goes to the point of pricing.

When the F-150 Lightning Pro, the entry-level version for contractors only, was announced in May 2021, it had an MSRP of $39,974. This was hailed as a breakthrough.

But times change. And now that MSRP is $55,974. Materials costs and the like, don’t you know. The XLT starts at $63,474. $74,474 for the Lariat. And $96,874 for the Platinum.

However, to put this into context, know that for the gasoline F-150, the XL model starts at $33,695 and the top-of-the-line Limited at $84,910.

But while the Lightning is similar to the standard F-150, it isn’t the same as a standard F-150.

And because of that difference, because the Lightning is different from anything available right now (yes, there are other EV pickups, including the HUMMER, Rivian R1T and the Lordstown Endurance (also a finalist for the NACTOY truck award)), because it is a truck engineered and built by truck people who have been joined by an array of technologists, there is an impressive, implicit value proposition.

///

Fascinating Tesla Manufacturing Video

The Tesla Model Y. (Image: Tesla)

The Tesla Gigafactory Berlin-Brandenburg opened earlier this year. The factory builds the Model Y.

In October Tesla announced it was producing 2,000 vehicles per week.

Earlier this month the workers at the plant hit 3,000 per week.

If you:

- Love Tesla

- Could care less about Tesla but are interesting in manufacturing

- Like impressive video

- Want a worthwhile diversion

Take a look at this.

///

Wham-O and Micromobility

The Zectron e-bike. Brought to you by the folks from Wham-O. (Image: Zectron)

Remember the Wham-O Superball, the ball that could bounce impossibly high?

Wham-O still exists. And it has launched the Zectron e-bike.

While the bike doesn’t bounce per se (there are a dynamic rear suspension system and a seat stay that suspends the saddle meant to handle bouncing), it folds.

The Zectron is 59 x 26 x 42 inches unfolded. It is 33 x 25 x 31 inches folded.

The magnesium frame notwithstanding, it weighs 55 pounds.

Of course, as it is an electric vehicle it tends to be heavier than non-electric versions (this holds for cars, too).

It has a lithium-ion battery that has a capacity of 36 V, 417.6 Wh. Another battery of this size is available for those who are interested in extending the range: it can travel up to 35 miles on a battery alone (double that with the extra battery); if one provides pedal assistance it is extended to 70 miles (or 150 miles, though it isn’t clear where the extra 10 miles come from).

Charge time on the outlet in your loft is 5.5 hours.

The bike is powered by a 350-W brushless hub motor produced by Bafang Electric. It provides a top speed of 20 mpg.

Also like four-wheeled EVs, the Zectron offers selectable drive modes.

There are:

- Pedal-only (the company acknowledges that this will provide “good exercise”—remember: 55 pounds)

- Pedal-assist

- Throttle only

Two Things to Know

- Wham-O, incidentally, also brought us the Hula Hoop. According to the company, four months after the Hula Hoop was introduced in 1957, 25 million were sold. According to eBicycles.com, in 2023 e-bike sales are expected to reach 40 million units. So that hoop number is awfully impressive. Of course, back then the hoop retailed for $1.98, which in today’s dollars is $20.40. the Zectron will set you back a double-digit multiple of that (when I looked at the Wham-O site it had a list price of $1,999 and a sale price of $999).

- Zectron? That’s the name of the material that the Superball is made with. Like many developments, the ball “was created by a chemical engineer on accident.”

///

Solid-State Batteries Briefly

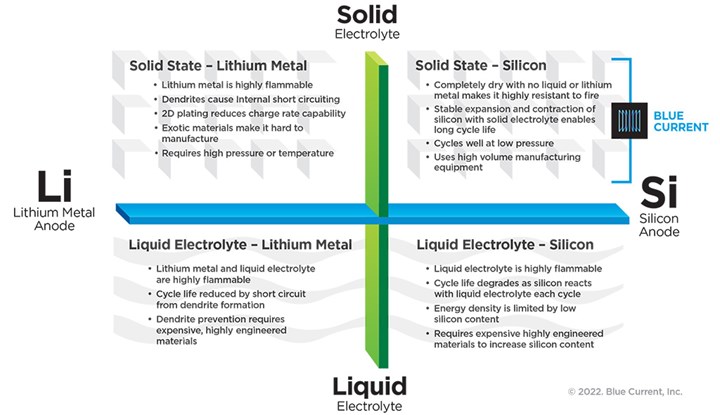

Think of this as a quick guide to the differences between some battery chemistries. (Image: Blue Current)

You’ve probably heard a lot about solid-state batteries for electric vehicles.

And you probably don’t know a lot about solid-state batteries.

That infographic above provides a sufficient amount of information for most purposes.

Blue Current, the company that developed it, is a spinoff from the Joint Center for Energy Storage Research (JCESR):

“JCESR creates and proves the ideas that eventually go commercial. These are the riskier ideas that no investors would fund—and that companies are unlikely to pursue—because the outcome is so uncertain.”—George Crabtree, JCESR director and an Argonne senior scientist.

Now investors are involved: Blue Current got a $30-million investment from Koch Industries to build a pilot plant in Hayward, California.

What They’re Doing

The Blue Current approach is essentially this:

- Glass ceramics have good conductivity, but don’t stick to the chemically active battery electrode materials that store lithium ions

- Polymers have poor conductivity but stick to the electrode materials

- Blue Current mixes the two materials thereby creating a composite

“The idea of using composites in batteries was new and unproven prior to the JCESR program. JCESR put resources behind composites because the materials had potential to address a market need for safe, solid-state batteries while solving important technical challenges.”—Kevin Wujcik, Blue Current Chief Technology Officer

\\\\\\\\

RELATED CONTENT

-

Report Predicts Limited Impact of Autonomous Tech on Professional Drivers

A new study says autonomous vehicles will displace some taxi drivers but have only a modest impact on the number of truck driver jobs over the next 10 years.

-

On Electric Pickups, Flying Taxis, and Auto Industry Transformation

Ford goes for vertical integration, DENSO and Honeywell take to the skies, how suppliers feel about their customers, how vehicle customers feel about shopping, and insights from a software exec

-

Rage Against the Machine

There have been more than 20 reported attacks against Waymo’s self-driving fleet in Chandler, Ariz., since the company began testing the technology on public roads there two years ago.

.jpg;width=70;height=70;mode=crop)