On EVs, Tires, and Batteries

Building batteries, testing tires, autonomous rides, carbon-oriented design and execution, and a composite Jeep component explained.

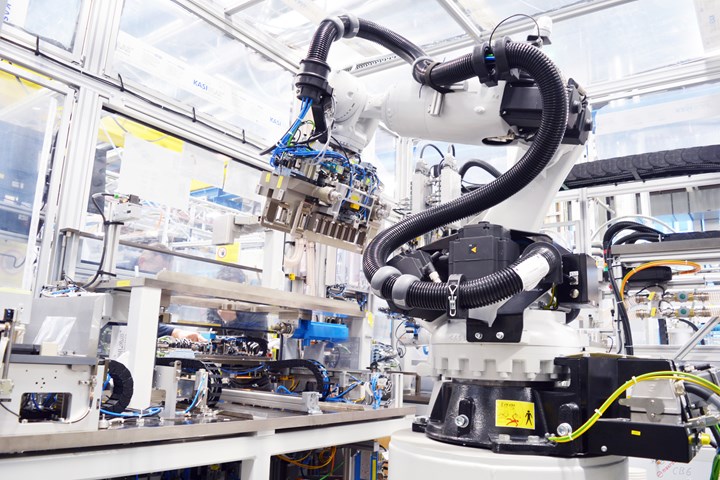

Bosch Building the Competition in Batteries

Bosch builds batteries and the automation to build batteries—and has external customers for both. (Image: Bosch)

“We know batteries like the back of our hand, as well as how they have to be manufactured,” says Rolf Najork, the member of the Bosch board of management responsible for industrial technology.

Bosch is involved in making batteries of various types, such as 48-volt batteries at its plant in Eisenach, Germany, for hybridizing vehicles and high-performance batteries for e-bikes at its plant in Miskolc, Hungary.

Generally companies with the know-how and the wherewithal to produce something keeps that internal.

Not Bosch.

It is monetizing that capability. And hopes to general annual sales of some 250-million euros by 2025 by selling its mechanical engineering expertise and production equipment.

This includes equipment, machinery, hardware and software for producing battery modules and packs, be they cylindrical, prismatic or pouch.

An early customer is Webasto, which is producing batteries at a plant in Schierling, Germany, with Bosch equipment.

Provided are automated assembly lines. There’s cell cleaning with incoming inspection stacking, laser-welding and end-of-line inspection. Robots then assemble the cell stacks with both an adhesive and laser welding. The modules have electrical connections added via laser welding.

“Our assumption,” Najork says, “is that the global battery market will grow up to 25% each year.”

Which means a growing demand for production equipment.

///

Mario Andretti Is 81 and Can Drive Like He’s 20

What came first: the compound or the pattern? (Image: Bridgestone)

While tires are something we don’t think about a lot (until this on Automotive, as you’re about to see), we did watch the introduction of two new tires from Bridgestone, the Potenza Sport and Potenza RE980AS+.

These are both in what is known as the “ultra-high performance” category.

As in these are the tires you’re going to be putting on a BMW, Acura NSX or Ferrari of some particular flavor.

Or you could, like the German magazine Auto Bild Sportscars did, put them on a Mustang with a 5.0-liter under the hood. (It was a comparison tire test. The Potenza Sport won.)

To put the tire through its paces in the U.S. intro Bridgestone put Mario Andretti on a racetrack and let him have at it.

This is somewhat surprising:

The number of sizes they are available in. The Potenza Sport in 65 sizes covering 81% of sports cars and sedans on the road (post-2012) and the RE980AS+ in 53 sizes, covering 85% of the same.

OK. . .

The point of both tires is performance.

For the Potenza Sport a point of emphasis is that there is an ultra-high use of silica in the compound and a specially designed tread pattern geometry as well as 3D sipe technology.

For the Potenza RE980AS+, there is the use of soybean oil in the compound (it apparently helps with things like wear and driving in the snow), as well as an asymmetric tread design.

Which led us to wonder:

What has the biggest effect on tire performance, the compound or the tread design?

So we asked Dale Harrigle, chief engineer, Performance and Luxury Replacement Tires, Bridgestone Americas, and this is what we learned:

“In general, the tread compound and materials used can have slightly more impact on the performance of the tire than the tread pattern geometry. The RE980AS+ is a great example of this—with a tread compound change, Bridgestone was able to improve the tire’s performance in winter conditions and provide slightly better wear, while keeping the same tread pattern geometry as the previous generation RE980AS. As we develop new tires, Bridgestone typically develops the tread pattern and compound in tandem, in order to best match the tread pattern to the compound performance.”

///

Rolling Smart

Smart tire for electric, autonomous truck. (Image: Einride)

Einride is a Swedish company that focuses on electric vehicles that are (1) autonomous and (2) carry freight.

According to the company it is presently operating the largest fleet of electric trucks in Europe.

And as it is making its way to the U.S. market, Einride and Bridgestone have established a partnership for electrified and autonomous Class 8 trucks (a.k.a., “big rigs”).

Einride brings the trucks and digital services for Bridgestone for its U.S.logistics network. Bridgestone brings the tires. Smart tires.

Niklas Reinedahl, General Manager, Einride North America: “We have an ambitious business plan for electric and autonomous transportation in the U.S. as well as innovative plans to improve our capabilities by leveraging tire-as-a-sensor technology and insights derived from the tire telematics data.”

///

Hush

That silver/gray on the inside is the quiet-enhancing tape. (Image: Avery Dennison)

And finally this (no, we won’t make a joke about being tired).

“As elevated traffic density and drive-by-noise have been recognized as environmental issues, legislation to manage and reduce this impact has led to measures in many regions to reduce the noise emitted by tires,” said Scott Krusinski, product manager, Automotive & Other Transportation, Avery Dennison.

Yes, even the noise from tires can be problematic, and not just for occupants of a given vehicle.

Krunsinski continued, “In addition, with the emergence of electric vehicles and less engine noise, the need to reduce interior vehicle noise has increased.”

Avery Dennison? Isn’t that the company that produces things found in offices everywhere, such as labels?

Yes.

But there is the Avery Dennsion Performance Tapes operation.

Which has developed a new portfolio of tapes (a.k.a., “pressure sensitive adhesive solutions”) for tire OEMs.

These tapes help bond noise-absorbing foam to the inside surface of tires.

The construction is said to resist flexing, compression and impact.

The bonding to the tire bladder doesn’t require heat or cure time so manufacturing operations aren’t affected.

And all this means quieter tires.

///

Apolong: The Next Generation

Introducing the Apolog II. (Image: Baidu)

We will admit that we missed Apolong I.

But now there is Apolong II.

What?

It is a “multi-purpose autonomous minibus” launched by Baidu in the Guangzhou Huangpu District.

The configuration lends itself to being used for applications ranging from public transit to mobile policing.

A significant difference between the I and II is 3 (or III).

That is, the computing power of the new electric vehicle is three times that of the previous model.

372 TOPS (trillions of operations per second).

One of the benefits of all of that computing capability: while the Apolong I models, which have been on the roll since July 2018 and have accumulated some 120,000 km, operate in urban parks, somewhat controlled environments, the Apolong II is capable of operating on open roads, being able to do things like make unprotected left turns and lane changes.

The sensors include lidar, radar and cameras. The range is up to 250 meters and the positioning accuracy is said to be within centimeters.

The vehicle uses Baidu’s vehicle-to-everything (V2X) tech and 5G remote driving service.

Screen Size

Nowadays, a new vehicle means a bigger infotainment screen.

The Apolong II is no different. It has a 55-inch screen Baidu and BOE Technology developed.

It is a transparent screen that allows passengers to see the road conditions and how the autonomous system is operating.

Passengers can also use the DuerOS assistant (think Siri or Hey Google) to make navigation requests.

We’ll keep an eye out for Apolong III.

///

When You Don’t Have a Parking Space (But Where Does the Scooter Go?)

Conti and Varta teamed for a battery system for scooters. (Image: Continental)

“Continental Engineering Services and Varta have jointly developed an attractive solution for commuters without their own parking space,” says Alex Rupprecht, Director Business Segment Driveline & Electrification at Continental Engineering Services (CES), a subsidiary of Continental AG, a leading automotive supplier.

What he’s talking about is a replaceable 48-volt battery pack for scooters.

It is rated at 10 kW, which is said to provide a scooter—comparable in performance to a gasoline powered 125-cc powered bike—with a range of 50 km (31 miles).

Varta—a 130-year-old company that specializes in batteries-from micro to energy storage systems—provided its V4Drive high-performance lithium-ion cell. CES is providing its battery management system.

Electric scooters aren’t a novelty. Neither are electric scooter batteries.

But apparently, many e-scooters are comparable with 50-cc scooters, which are not exactly commuting-to-work capable.

One of the interesting things about this battery is that it is engineered so that it can be readily swapped out with a replacement as it weighs 9 kg (~20 pounds).

Evidently the battery management system permits the control of more than one battery. But, no, two batteries wouldn’t make the bike faster, just extend the range to 100 km.

///

Going Green; Looking Good

Kia paid attention to the design—and the emissions associated with the forthcoming EV6. (Image: Kia)

The 2022 Kia EV6 crossover is a real car. Yes, it looks like a futuristic concept. But early next year it will be made available in all 50 states.

And while that reference to states focuses on just the U.S., know that the EV6 is but one of 11 electrified models that Kia will launch globally.

Some quick things to know:

- Features a 77.4-kWh high-density lithium-ion battery for a range approximately 300 miles

- A 800-V multi-charging architecture permits 350-kW DC fast charging of 10% charge to 80% charge in <18 minutes

- It has a 114.2-inch wheelbase that is said to be comparable to a Tesla Model Y, a ground clearance matching the Y, and a width on par with the Mustang Mach-E (74.1 inches)

Carbon Down

The EV6 is the first vehicle from a Korean manufacturer to obtain the “Carbon Measurement” label from the Carbon Trust, a consultancy that helps companies reduce their carbon footprint.

The total greenhouse gas emissions—from extracting the raw materials to manufacturing to end-of-life handling—were calculated using the PAS 2050 standards.

So Who Did What?

How did this certification come about?

We asked the Carbon Trust.

And learned:

“Kia developed the EV6 vehicle themselves based on their own specifications as well as calculating their own carbon footprint for the vehicle.

“Carbon Trust partnered with Networks Y [a Seoul-based environmental consultancy] and acted as independent third party to assess that the calculations and ensure these were done in accordance with the recognized standards, in this case:

- PAS 2050: 2011 – Specification for the assessment of the life cycle greenhouse gas emissions of goods and services

- Greenhouse Gas Protocol – Product Life Cycle Accounting and Reporting Standard (2011)

- ISO 14067 (2013) - Greenhouse gases — Carbon footprint of products — Requirements and guidelines for quantification and communication”

The EV6 certainly has green bona fides. And looks great, to boot.

///

Light & Capable for Jeep

Composite structure engineered to provide tranmission support—on the underside of a Jeep Grand Cherokee L. (Image: BASF)

When it comes to engineering structural components for vehicles, crash energy management is always a key concern.

It is interesting to hear providers of steel and aluminum talk about their materials’ inherent goodness in this capability to route forces in a predictable pattern.

So it came of interest that the 2021 Jeep Grand Cherokee L has a component that is part of the transmission mounting system that transfers the energy load from a collision from the outer rail to the transmission mount crossmember that is made with. . .a composite.

The CTR—composite tunnel reinforcement—is produced by supplier L&L Products using a pultrusion process (Continuous Composite Systems) and a polyurethane chemistry, both from BASF.

Brian Dwyer, Chassis Engineering Manager, Stellantis, said of te CTR: “It’s not easy to find a weight reduction solution that improves overall performance but’s that’s exactly what we have done on the 2021 Jeep Grand Cherokee L composite tunnel.”

Oh, and there’s this:

Know that the CTR is located on the underside of the vehicle. And Grand Cherokee Ls often are very familiar with off-road conditions that would crumble less-capable structures.

So evidently rock energy management was taken into account, as well.

RELATED CONTENT

-

Cobots: 14 Things You Need to Know

What jobs do cobots do well? How is a cobot programmed? What’s the ROI? We asked these questions and more to four of the leading suppliers of cobots.

-

TRW Multi-Axis Acceleration Sensors Developed

Admittedly, this appears to be nothing more than a plastic molded part with an inserted bolt-shaped metal component.

-

GM Develops a New Electrical Platform

GM engineers create a better electrical architecture that can handle the ever-increasing needs of vehicle systems

.jpg;width=70;height=70;mode=crop)