on Transmissions, Cleaner Steel, Robotics, EV Batteries & More

Still lots of manual transmissions. . .steel production with reduced emissions. . .EVs drive robot sales. . .humanoid robots and testing issues. . .battery costs and EV efficiencies. . .Toyota Highlander. . .popular Chinese EV in the U.K.

#robotics

Quick Transmission Quiz

Manual transmissions are (1) surprisingly popular and (2) something many people in the U.S. may not know how to use. (Image: MINI)

Given the following transmission categories*, what do you think the rankings would be (on a global basis):

- Automatic

- CVT

- DCT

- Manual

According to AutoForecast Solutions, the number-one type of transmission is the automatic—but not overwhelmingly.

While AFS separates the automatic into two categories, ≤6 speed and ≥7 speed, if the two are combined (9.6% and 23.4%, respectively), the total is 33%.

But closely behind that is the manual transmission, at 31.4% of consumption.

According to Sam Fiorani, vice president of Global Vehicle Forecasting at AFS, “This is largely due to China, where manuals still make up a large portion of the market.”

He points out, for example, that the recently launched Haval Jolion CUV is available with a seven-speed DCT or a six-speed manual.

Imagine a new Chevy Equinox or Ford Escape—not some sort of “performance” variants, just standard setups—being offered with a manual gearbox.

Fiorani says that while manuals are giving way to automatics (including CVTs and DCTs) in Europe, the continent is still a contributor to the manual numbers.

A “Rite of Passage”?

MINI USA recently conducted a consumer survey on the subject of manual transmissions.

According to MINI, “an impressive 63% of all respondents agree that learning how to drive a manual transmission is a rite of passage and an important life skill.”

I think that should be “an unbelievable 63%.”

And its own findings bear that out, as 49% of the respondents in Gen Z and 42% of all women say they don’t know how to drive a manual.

Hard to correlate that with the “rite of passage” and “important life skill.”

MINI USA is now offering manuals in an array of its models (it announced four more last week).

And it has opened registration for a learn-how-to-drive-a-manual school being conducted in California. Tuition? $499.

==

*Electric vehicles are not included in the numbers as their transmissions are generally unlike traditional multi-speed units.

///

Cleaner Steel

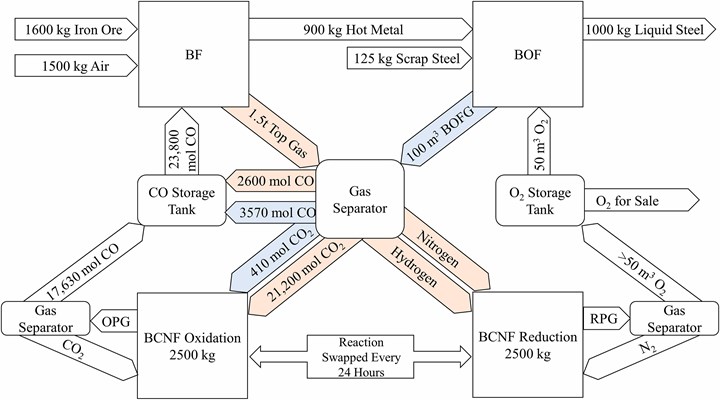

Making steel production environmentally improved. (Image: University of Birmingham)

Assuming that emissions reductions are a big driver of the move toward electric vehicles, there is another thing to think about:

The materials with which the vehicles are produced.

Like steel.

According to researchers at the University of Birmingham, “Iron and steelmaking is the biggest emitted of CO2 of all foundation industrial sectors, accounting for 9% of global emissions.”

There are approaches to make steelmaking more environmentally benign.

Such as using electric arc furnaces powered by renewable electricity.

Professor Yulong Ding, of University of Birmingham School of Chemical engineering, points out that an electric arc furnace plant can cost over £1 billion to build and it takes time to get it up and running.

Process Improvement

So Ding and colleagues have devised an alternative.

Professor Ding: “The system we are proposing can be retrofitted to existing plants, which reduces the risk of stranded assets, and both the reduction in CO2, and the cost savings, are seen immediately.”

He and his colleagues have come up with a system wherein the amount of coke used in steelmaking is greatly reduced and a double perovskite is used for thermochemical splitting of CO2.

As it is put in the paper published in the Journal of Cleaner Production: “The CO produced by the TC [thermochemical] cycle replaces expensive metallurgical coke for the reduction of iron ore to metallic iron in the blast furnace (BF). The CO2 produced from the BF is used in the TC cycle to produce more CO, therefore creating a closed carbon loop, allowing for the decoupling of steel production from greenhouse gas emissions.”

And that’s the easy bit.

Dr. Harriet Kildahl, co-author of the paper and colleague at the University of Birmingham, notes that blast furnaces currently produce about 70% of the world’s steel.

She says of the process they’ve developed: “This system could be retrofitted to existing blast furnaces meaning costs are lower, emissions reductions are seen more quickly and the existing global fleet of blast furnaces can be used, saving jobs and reducing the risk of stranded assets.”

(As you may recall from your world history class, in the 19th century the U.K. was the world’s leading producer of steel and iron.)

Simply Know This

- Making steel creates lots of emissions

- Plenty of steel is used in auto and other industries

- There is a considerable number of existing steel plants

- These University of Birmingham researchers have devised a way to reduce emissions while not scrapping existing blast furnaces

- While there are other methods of producing steel in a “greener” manner, this process can go into production more quickly

///

PVD, Carbon Fiber, Palladium. . .

Technically advanced (materials, process) Bugatti eyewear. (Image: Bugatti)

Physical vapor deposition (PVD) is a process used in some industrial applications like the fabrication of tools that can cut metal: the coating deposited can be exceedingly hard.

PVD is also used in other applications, including coating some trim pieces and lamp assemblies because the coating can be thin, durable and attractive.

PVD is something (as you’re probably aware) that doesn’t come up often.

Carbon fiber, of course, is widely used in performance cars, whether those cars are daily drivers, driven only on tracks, and/or kept in multi-vehicle heated garages (because they tend to be rather expensive and so people who can afford them can generally afford several vehicles).

Another automotive material that has automotive applications is palladium. It is deployed in catalytic converters. However, the move to EVs is making this precious metal less precious (i.e., EVs don’t have catalytic converters, so. . .). A recent Reuters story quotes an analyst at Bank of America who said, “Palladium is a one-trick pony. Demand relies pretty much 90% on the auto industry.”

PVD. Carbon fiber. Palladium. . . Eyeglass frames.

Huh?

A line of frames, “Collection One,” was designed for Bugatti by Larry D. Sands, who is described as “a freethinking pioneer in the optical fashion space.”

It took him two years to develop the nine frame styles.

He uses PVD, carbon fiber and palladium for the glasses.

Presumably, these specs are going to required car-loan money.

Oh. And 925 sterling silver and Macassar ebony are also used for the frames.

///

EVs and Robots

“Automotive OEMs and components suppliers alike recognize that investing in robots is instrumental to the emergence of EVs as well as to manufacturing all vehicles as they compete to meet customer demand.”-- Jeff Burnstein, president of A3.

That is a fundamental reason why the Association for Advancing Automation (A3) found that the North American robotics market set new unit and value records in 2022.

Compared with 2021, the previous record year, there were orders for 44,196 robots valued at $2.38 billion, which are increases of 11% and 18% respectively.

Of the units, 23,807 were ordered by the auto industry. That’s ~54%.

And of that total, 13,042, or ~55% were ordered by automotive suppliers.

Plenty of Material Handling

Although it is a aggregate number for all industries and not just automotive, the 24,595 robots ordered for material handling applications dwarfs all application categories: spot welding is second, at 8,594.

///

Walking Robots at Work

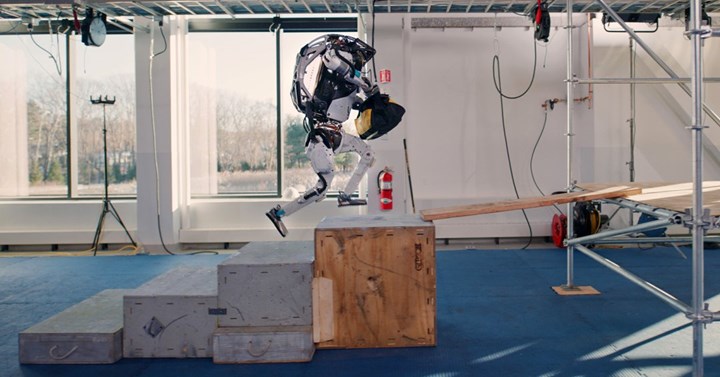

Atlas carrying a bag of tools. (Image: Boston Dynamics)

Speaking of robots. . .

Boston Dynamics, the company that is developing and producing robots resembling animals and people, recently took its Atlas humanoid robot and put it to work.

In previous endeavors, Atlas was shown dancing and performing parkour, not vocational activities unless you’re talking Broadway or Las Vegas.

Ben Stephens, control lead for Atlas, wrote in a blog post:

“Parkour and dancing were interesting examples of pretty extreme locomotion, and now we’re trying to build upon that research to also do meaningful manipulation. It’s important to us that the robot can perform these tasks with a certain amount of human speed. People are very good at these tasks, so that has required some pretty big upgrades to the control software.”

The tasks he is referring to has the robot, in effect, at a work site where it is tasked with delivering a tool bag. Of course, Atlas also climbs stairs, moves a large block of wood, jumps between levels, performs a 540° flip that Tony Hawk would admire. . . .

Although Stephens acknowledges humanoid robots doing work like that performed in the exercise (which you can see here) is a “long way off,” presumably that is the goal.

The Importance of Testing

And while on the subject of machines like those being developed by companies including Boston Dynamics. . .

A study conducted by researchers at The Ohio State University on legged robots found that there is a level of unpredictability with them.

Bowen Weng, a PhD student in electrical and computer engineering at OSU:

“Our work reveals that these robotic systems are complex and, more importantly, anti-intuitive.

“It means you can’t rely on the robot’s ability to know how to react in certain situations, so the completeness of the testing becomes more important.”

Weng and his colleagues have developed a data-driven, scenario-based safety testing framework:

“Testing is really about assessing risk, and our aim is to investigate how much risk robotics currently presents to users or customers while in a working condition.”

The paper Weng and colleagues produced was published in the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) 2022.

///

Some Takeaways from the BloombergNEF San Francisco Summit

Overall vehicle efficiency is important for EV range. The Lucid Air is efficient. (Image: Lucid)

Where they talked (in part) about EVs and related tech. . .

~Battery Prices?

Back in 2010, the volume weighted average price for a lithium-ion battery pack was $1,306/kWh.

In 2021 it was $141/kWh.

An 89% decrease, noted Evelina Stoikou, associate, Energy Storage, BloombergNEF.

She acknowledged that in 2022 the price increased to $151/kWh. A 7% rise.

But she says there is an expectation that in 2024 prices will begin their decline.

Part of this is something of a virtuous cycle as higher prices cause a shock in the industry, which leads to capacity expansion (raw materials, to battery components to cells), which leads to lower prices, which leads to high demand, which leads to high battery prices. . . .

The tipping point for EVs is when battery pack prices hit $100/kWh, which puts EVs at price parity with ICE vehicles. Stoikou said BloombergNEF has adjusted its expectation of when that it going to happen.

In 2021 they expected it to occur in 2024.

Now 2026.

~Battery Size & Infrastructure

On the subject of the size of batteries, Alex Haring, senior associate, Advanced Transport, BloombergNEF, pointed out that when there is insufficient infrastructure for charging, people want larger batteries. (Bigger batteries can mean less range anxiety.)

He noted that as a practical manner, 100+ kW fast chargers are needed for public charging.

Using numbers from Q2, ’22, he said that there are 21,500 chargers like that in the U.S.—of which two thirds are part of the Tesla network.

Of the other 7,500, 78% of them are part of the Electrify America network.

Haring explained that Electrify America is an atypical charging system operator as it is predicated on a 10-year mandate from the U.S. Justice Department to spend $2-billion on charging. Which, he suggested, has resulted in a “gap in incentive” for the company, citing the performance of the company in the J.D. Power 2022 U.S. Electric Vehicle Experience—Public Charging Satisfactory Study, wherein for DC fast chargers Electrify America was at 614 points on a 1,000-point scale while Tesla was at 739.

Haring said that given that Electrify America has been in operation for four years and EVgo, which scored 573 points, for 10 years so these are “not growing pains, but a real problem.”

The number of chargers is one thing. Whether those chargers work is something else entirely.

~Vehicle Efficiency & Steph Curry

Corey Cantor, senior associate, Electrified Transport, BloombergNEF, said that OEMs need to focus on “efficiency” for EVs.

As the presentation was in San Francisco, he used Golden State Warriors’ Steph Curry as an analogy.

He said that Curry is really good at sinking three-point baskets. “Threes are more efficient than twos.”

Cantor explained that better vehicle efficiency boosts range so it isn’t necessary for an ever-increasing battery size. (He was countering Haring.)

A measure that he used for EV efficiency is miles per kWh.

He pointed out that in the large sedan category, the BMW i7 is at 3.0 while the Lucid Air is at 4.6, or a 50% advantage in efficiency.

In the medium SUV category, the new Nissan Ariya is at 3.2 while the Tesla Model Y is at 4.2, or a 30% advantage.

“EV automakers,” Cantor said, “need to think like Steph Curry—more efficient.”

///

2023 Toyota Highlander Hybrid Platinum AWD

The Toyota Highlander: for those who need to bring along family and friends. (Image: Toyota)

Let’s put the forthcoming Grand Highlander aside.

The “regular” Highlander is an impressively imposing vehicle, especially if you look at the fourth generation (the current one) and compare it with the third generation.

As in:

Now:

- 112.2-inch wheelbase

- 194.9-inch length

- 76-inch width

- 68.1-inch height

Then:

- 109.8-inch wheelbase

- 192.5-inch length

- 75.8-inch width

- 68.1-inch height

Yet, although that length and wheelbase increase are visibly impressive, know that compared to the current generation Ford Explorer, another midsize SUV, the Highlander is smaller.

Explorer:

- 119.1-inch wheelbase

- 198.8-inch length

- 78.9-inch width

- 82.7-inch height

Which probably goes to the point of Toyota coming up with the Grand Highlander, but let’s leave that for another day.

(BTW: why the comparison? The two are competitive in the market. In 2022 Highlander sales were 222,805 units, with Explorer at 207,673.)

The Highlander design team have cleverly created a look for the vehicle that is on the one hand robust (if “trucky” was a word, that would be the one to be used here) and on the other sophisticated.

And as the vehicle driven here is the top-of-the-line Platinum, it has amenities galore, including a power panoramic view (think the entire roof space) moonroof with sunshade and one-touch open/close ; 20-inch alloy wheels; height-adjustable hands-free power liftgate; power-folding mirrors; LED projector, adaptive headlights (turn right and the headlights’ beam shifts in that direction) on the outside. . .

. . .and on the inside, seating for seven (captain’s chairs in the second row); a 12.3-inch multimedia screen with wireless Android Auto, Apple CarPlay and Amazon Alexa compatibility; a 12.3-inch digital instrument cluster (yes, as big as the infotainment screen); a 10-inch color head-up display; a bird’s eye view camera (while it may not be the biggest, this is a big vehicle so cameras help for parking); three-zone automatic climate control; and more.

This particular model is a hybrid. There are gas-only vehicles with a 265-hp, 2.4-liter turbocharged four. This model has a 2.5-liter four with two electric motor-generators, which provides a system horsepower of 243.

But the number that is remarkable: 36. That’s the EPA-estimated combined miles-per-gallon rating.

Consider: comfortable seating for seven (although the third row isn’t bad, let’s agree that the vehicles that offer measurable room behind the second row tend to be painted yellow and you were smaller when you rode in them) and you’re getting that kind of mileage.

Oh. And it can tow up to 3,500 pounds.

Base MSRP for this model? $52,625.

///

What Do Brits Want to Drive?

The MG HS was the top-selling vehicle in the U.K. in January. The British brand notwithstanding, the SUV is built in China. (Image: MG)

What was the number-one selling vehicle in the U.K. last month?

The MG HS, an SUV, which is available in “petrol or plug-in hybrid specification.”

According to the Society of Motor Manufacturers and Traders (SMMT), there were 3,481 of the vehicles sold in January in the U.K.

Another MG model was in the top 10 sales list, too, the ZS, a compact SUV, at number 8.

Why Is This Interesting?

While a vehicle that had monthly sales of 3,481 might otherwise deserve a shrug, the MG brand, which was established in 1924, is interesting in that it is owned by SAIC Motor Corp., a state-owned Chinese vehicle manufacturer.

And the MG HS is built in China.

It is worth noting that other legendary British brands have owners that aren’t synonymous with fish and chips:

- Rolls-Royce Motor Cars: BMW

- Bentley: Volkswagen AG

- MINI: BMW

- Lotus: Geely

- Jaguar: Tata Motors

RELATED CONTENT

-

Frito-Lay, Transportation and the Environment

Addressing greenhouse gas reduction in the snack food supply chain

-

On Ford Maverick, Toyota Tundra Hybrid, and GM's Factory Footprint

GM is transforming its approach to the auto market—and its factories. Ford builds a small truck for the urban market. Toyota builds a full-size pickup and uses a hybrid instead of a diesel. And Faurecia thinks that hydrogen is where the industry is going.

-

On Military Trucks, Euro Car Sales, Mazda Drops and More

Did you know Mack is making military dump trucks from commercial vehicles or that Ford tied with Daimler in Euro vehicle sales or the Mazda6 is soon to be a thing of the past or Alexa can be more readily integrated or about Honda’s new EV strategy? All that and more are found here.

.jpg;width=70;height=70;mode=crop)