Smarter Adaptive Cruise for Truck Fleets

Startup targets 10%+ fuel efficiency gain

Like many automotive engineers, Ali Maleki has had to temper his expectations for autonomous vehicles in recent years.

He once thought the technology would be available by this time. Now Maleki doesn’t expect widescale deployment until about 2030.

But he still recognizes the potential convenience, safety and environmental benefits. And he’s doing something about it.

Gaining Traxen

In early 2018, Maleki founded Traxen, a Plymouth, Mich.-based startup that’s developing an intelligent adaptive cruise system, which he claims can provide a 10% or more fuel efficiency boost for commercial trucks.

Image: Traxen

Maleki knows a lot about adaptive cruise control. He’s been working on the technology—and other driver-assist systems—for more than 20 years. (His resume includes stints at Nexteer—his most recent stop, where he was executive director of innovations and next ventures—Ricardo, Fisker, Coda Automotive, Meritor, Bendix, Visteon and Continental.)

In launching Traxen, Maleki aims to apply his experience to benefit current vehicles—including aftermarket retrofits—and start down the path toward full autonomy.

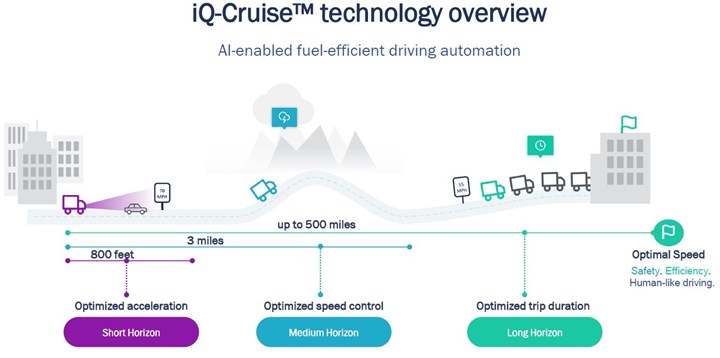

The result: iQ-Cruise, an artificial intelligence-based system that Maleki calls adaptive cruise control on steroids.

How It Works

In addition to maintaining a set speed and slowing down as necessary based on the preceding vehicle, iQ-Cruise takes into account upcoming conditions, such as changes in elevation, road curves, traffic patterns and even weather (through cloud-based telematics services) for miles beyond a driver's visual field.

By optimizing a vehicle’s speed over changing conditions, Maleki says iQ-Cruise can provide significant improvements in fuel efficiency for traditionally powered trucks and full-electric models.

This includes route planning at the beginning of a trip, taking into account a series of hills and navigating through heavy traffic with minimal braking, Maleki notes.

The Mechanics

The system consists of a domain control unit with multiple processors and redundancy, radar and camera sensors, and proprietary software algorithms.

High-definition mapping accessed through the cloud covers the bulk of highways and main roadways throughout the U.S.

The system currently is limited to operating speeds above 25 mph. But Maleki says there are plans to eventually add stop-and-go capabilities.

Traxen has eight patents pending on the technology.

Test Results

During a 6,100-mile round-trip drive this summer from Traxen’s Michigan headquarters to Las Vegas, Class 8 trucks outfitted with the iQ-Cruise were 7% more fuel-efficient than base models, according to field tests monitored by the North American Council for Freight Efficiency.

During the trip, iQ-Cruise was engaged about 90% of the time.

Enhancements made since then have shown 10% fuel economy gains during testing, according to the supplier. By 2023, after systemic learnings from an estimated 700 million miles of data obtained from customer drives, Traxen predicts the system will be able to achieve gains of 15%-20%.

The potential savings for electrified trucks can be even greater, Maleki says, by optimizing regenerative braking and reducing friction. He claims this could lead to as much as a 35% longer driving range.

Why Trucks?

Commercial trucks can benefit more from potential fuel efficiency improvements because they start from such a low mpg base.

Driving skill also plays a role. Maleki says a truck driver’s ability and style can impact fuel efficiency by as much as one-third, which means there’s a lot of room for improvement by limiting the driver’s role.

Trucks also are easier to equip because they are much more standardized than passenger vehicles, Maleki notes. He says iQ-Cruise can be installed in virtually any truck built within the last seven years, as long as it has an electronic engine controller, automatic transmission and modern CAN network.

In addition to lower fuel consumption, Traxen’s system also can reduce brake and tire wear, maintenance, insurance and training costs. All told, the supplier estimates that fleets can save an average of $5,000 per truck per year, which Maleki says would pay for the system in the first year.

What’s Next?

Traxen's system currently is being piloted by several fleet customers and will be available to aftermarket customers in the first quarter of 2021.

The company expects to equip as many as 7,000 trucks by 2023, with each truck accumulating more than 100,000 miles of test data each year.

Traxen also is working with several truck makers and plans to launch factory applications in coming years.

To encourage drivers to utilize the system, Traxen has developed a special user interface and app. The latter could provide a gaming aspect under which drivers would compete for the best fuel economy scores.

Fleets also could incentivize drivers based on how frequently they deploy the system and on fuel efficiency improvements, Maleki says.

RELATED CONTENT

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

-

TRW Multi-Axis Acceleration Sensors Developed

Admittedly, this appears to be nothing more than a plastic molded part with an inserted bolt-shaped metal component.

-

GM Develops a New Electrical Platform

GM engineers create a better electrical architecture that can handle the ever-increasing needs of vehicle systems