Cobots and Other Robotic Arms

Collaborative robots—which are perhaps best known by the blended “cobots”—are gaining plenty of attention.

#robotics

But what about all of the rhetoric one hears—again—about robots taking people’s jobs? Steve Barhorst, president and COO, says that that is more a phenomenon of the media than manufacturing; the companies that Motoman deals with find that the deployment of robots in their operations can become more efficient and that the people who are “displaced” are generally moved into more value-adding positions as the robots do the more repetitive work.

Collaborative robots—which are perhaps best known by the blended “cobots”—are gaining plenty of attention. And, yes, Motoman has it cobot, the six-axis HC10 that has a 10-kg (22-lb) capacity and is power and force limited (PFL), meaning that it can work without safety fences, and actually with workers (it complies with ISO and TUV safety standards). But there is a big but related to this. Christian points out that it is important that users perform a safety assessment because while the robot arm may not present a problem to a human worker, what’s on the end of the arm could be an issue (e.g., what if it has a sharp edge?). So the old “better to be safe than sorry” phrase comes into play even with cobots. What’s more, when it comes to the auto industry, Barhorst notes that one of the drivers behind cobots was to get deployment in industries that aren’t familiar with robotic technology. “Automotive knows how to use robots,” Barhorst says, almost as though he’s stating the obvious. Compared with other six-axis arms, cobots are generally slower and tailored for less complex applications. When you have a cadre of people who have long been putting robots to work in your factory, chances are given speed, positioning and other factors, the cobot isn’t going to be the choice.

Not that there aren’t a whole lot of newly developed robots that can handle an array of different tasks.

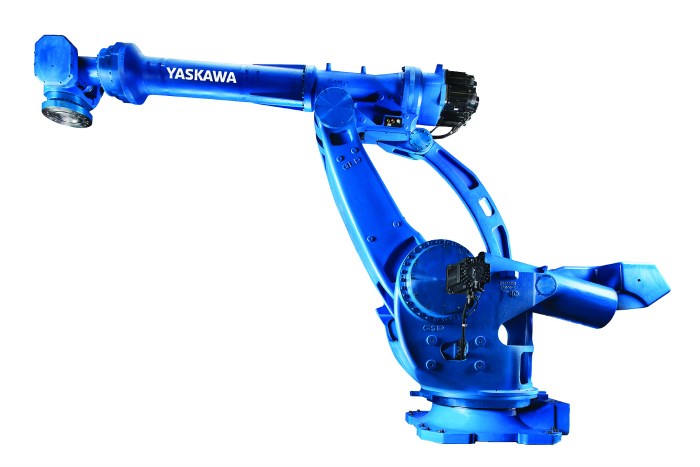

For example, there’s the six-axis MH900 with parallel-link construction. It has a 900-kg (1,984-lb) payload. Which means it can handle things like vehicle frames or bodies. It has a horizontal reach of 4,683 mm (184 in.) and a vertical reach of 6,209 mm (244 in.), so the work envelope is certainly relevant to the load capacity. The unit can do material handling, not only in the context of moving something from point A to point B, but also manipulate a part so that it could be worked on by other robots (think of it as serving the function of a fixture for, say, welding).

Then it goes to the opposite extreme, to the MotoMini, which is a six-axis robot but one with a 0.5-kg (1-lb) payload, a horizontal reach of 350 mm (14 in.) and a vertical reach of 495 mm (19 in.). The robot’s footprint is just 191 x 124 mm (7.5 x 5 in.). The MotoMini weighs 7 kg (15 lb) and readily lends itself to being mounted on a tabletop, floor, ceiling or wall.

Roger Christian’s title is based on “new business,” which can be considered to be a new application of equipment. This probably explains the EcoTrim workcells they’ve developed for the cutting and trimming of materials like headliners with ultrasonics. While there is material trimming performed with waterjet, Christian notes that among the differences between the two processes is that whereas the power requirement for a waterjet is on the order of 40 kW, it is 800 W for the ultrasonic tool that is fitted to the arm of a high-speed MH24 robot. The ultrasonic cut is clean and dry. They also offer other tools for cutting of fabric and plastic, including routers and knives.—GSV

RELATED CONTENT

-

GM Unit Stresses Driver Training in Autonomous Cars

General Motors Co.’s Cruise Automation unit says it puts backup drivers and auditors through extensive training before allowing them to participate in real-world autonomous vehicle tests.

-

Freudenberg Leans into Industry 4.0

CTO/COO Ted Duclos talks about dual roles and common objective

-

On Audi and Volvo's Green Initiatives, Bentley Design and more

Audi takes to the river to reduce plastic waste, Volvo focuses on a new category of consumers, Bentley once used a Bob Ross-approach during styling development, why Ford’s BlueOval City is the past brought to today, and some new terms that you should keep in mind

.jpg;width=860)

.jpg;width=860)