Face Milling Aluminum Without Burrs

Sandvik has developed a face milling approach that is analogous to rotary broaching

#aluminum

Whether it is a conventional ICE powertrain or a full battery electric setup, odds are that there is plenty of aluminum content, which means that there is machining involved. The material, notes Brent Marsh, business development manager for the Automotive Segment at Sandvik Coromant, is light, durable, corrosion-resistant, and strong, which are good for the end product, and is ductile, so it is comparatively easy to machine.

“But if you don’t cut it cleanly,” he warns, “there can be a burr.”

Burrs are always an issue. But in applications like valve bodies, they can be a real problem.

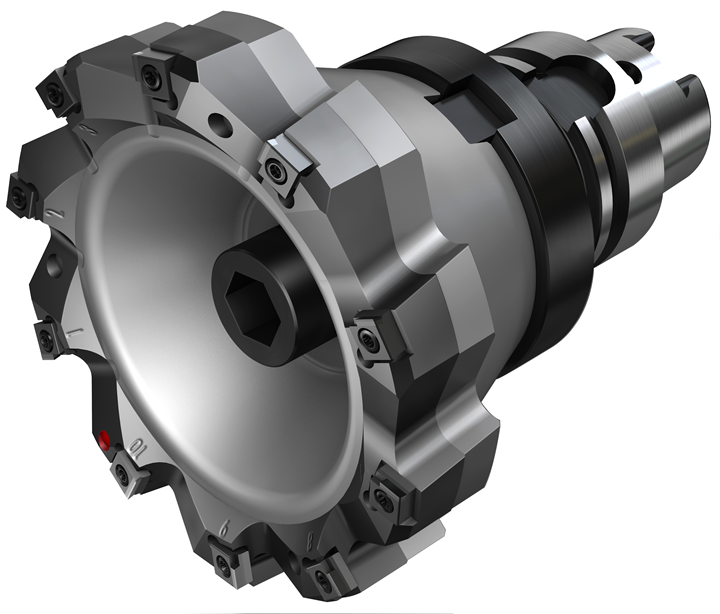

You don’t want burrs here. (Images: Sandvik Coromant)

According to Sandvik’s Rick Crabtree, automotive specialist for the Americas, while machining an aluminum valve body can be done in a matter of seconds, deburring can require minutes.

To address this problem, Sandvik has developed a new design for face mills.

Crabtree points out that ordinarily, all of the inserts on a mill are on the same plane. Burrs can be created when the tool goes into and out of parts. This is particularly the case when the cutter starts getting a little dull.

The M5 Series of milling cutters—which accommodate operations from roughing to finishing and even superfinishing—has been developed especially for aluminum alloys.

The M5B90 is engineered for face milling aluminum without burrs.

One of the features of the operation of the face mill is that it is, Crabtree explains, more like a rotary broach in operation in that not all inserts are on the same plane such that when the tool is moved out of the part there is a wiper action that inhibits the generation of burrs, as there is the removal of, say, 40 microns from the surface.

Consequently, machining is done quickly and post-processing is minimized, at most.

RELATED CONTENT

-

On Military Trucks, Euro Car Sales, Mazda Drops and More

Did you know Mack is making military dump trucks from commercial vehicles or that Ford tied with Daimler in Euro vehicle sales or the Mazda6 is soon to be a thing of the past or Alexa can be more readily integrated or about Honda’s new EV strategy? All that and more are found here.

-

On The Jeep Grand Cherokee, 2022 Nissan Pathfinder, and More

An inside look at the Detroit Assembly Complex-Mack; a innovative approach to waste-free, two-tone painting; why a forging press is like an F1 car; and other automotive developments.

-

On Zeekr, the Price of EVs, and Lighting Design

About Zeekr, failure, the price of EVs, lighting design, and the exceedingly attractive Karma

.jpg;width=70;height=70;mode=crop)