Is the Opposed-Piston Engine Becoming More Real?

Achates Power has been working on its opposed-piston engine technology—which it claims is more cost effective than a traditional engine (thanks, in part, to the elimination of such things as a cylinder head and valve train), easier to produce, and potentially “approximately 50% more efficient than today’s gasoline engines” (the Achates engine runs on gasoline, diesel, natural gas. . .)—since 2004.

Achates Power has been working on its opposed-piston engine technology—which it claims is more cost effective than a traditional engine (thanks, in part, to the elimination of such things as a cylinder head and valve train), easier to produce, and potentially “approximately 50% more efficient than today’s gasoline engines” (the Achates engine runs on gasoline, diesel, natural gas. . .)—since 2004. The company has developed plenty of demos and has received a respectable amount of outside investment.

It just may be that the opposed-piston engine may be getting closer to reality.

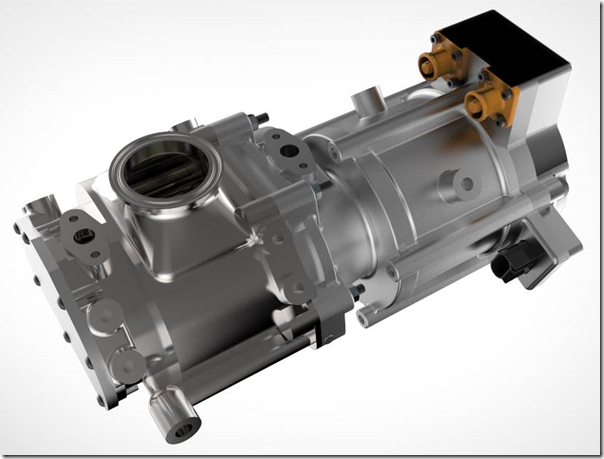

The reason? Eaton, which has provided its TVS air pumps to several Achates prototypes, announced today that it will be providing the air pumps for an engine that Achates will be running in a Class 8 commercial truck that is part of a demonstration program run by CALSTART, part of a $9-million grant funded by the California Air Resources Board.

This setup is expected to achieve a 90 percent reduction in NOx and as much as a 20 percent improvement in fuel economy.”

Assuming that numbers like that are hit, it would be hard to imagine that the Achates engine wouldn’t go commercial.

The TVS, incidentally, provides precise airflow into the engine, which is critical for the overall performance.

And the fact that Eaton is a company that produces products in volume (it has 2017 sales of $20.4-billion) indicates that it probably sees quite a positive upside for this new engine technology.

RELATED CONTENT

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

-

When Automated Production Turning is the Low-Cost Option

For the right parts, or families of parts, an automated CNC turning cell is simply the least expensive way to produce high-quality parts. Here’s why.

.jpg;width=70;height=70;mode=crop)