Manufacturing Plastic Parts with Light

Research with light-sensitive resins is changing the way production plastic parts can be made.

At the workshop on additive manufacturing at the 2019 North American International Auto Show, Ellen Lee, technical leader for additive manufacturing at Ford Motor Co. and Paul DiLaura, vice president of enterprise partnerships at 3D printing developer Carbon (carbon3d.com), discussed Ford’s first digitally manufactured polymer end-use parts. These include HVAC (heating, ventilation and cooling) lever arm service parts for the Focus, auxiliary plugs used in China-marketed F-150 Raptors, and parking brake brackets for the Mustang GT500.

Out of the Pool

The parts are made using Carbon’s proprietary technology, which differs from most polymer additive systems. Most of the latter build up the part layer by layer by depositing material one pixel at a time to lay out each individual layer. The Carbon DLS (Digital Light Synthesis) technology instead shines a pattern of ultra-violet light up to the bottom of a pool of resin—specifically, Carbon’s EPX 82, a high-strength material with long-term durability and mechanical properties comparable to glass-filled thermoplastics.

Where the UV light hits, the resin cures and hardens in the shape of a cross-section of the part. In a continuing process, the cured section raises up and more liquid resin comes in beneath it to be cured in turn.

The result is a solid part emerging fully formed from the pool, then further cured in an oven.

One of the advantages of the continuous nature of the process is that the finished part is more isotropic, with a smoother finish as well as a uniform interior, than 3D-printed parts produced in successive layers, Lee said.

How might the process—already, according to Carbon, up to 100 times faster than other additive methods—be improved? A possible answer may be found at UC Berkeley, which in late January demonstrated an additive system with some similarities to Carbon’s DLS—but also with some notable differences.

From Cross-section to Complete Workpiece

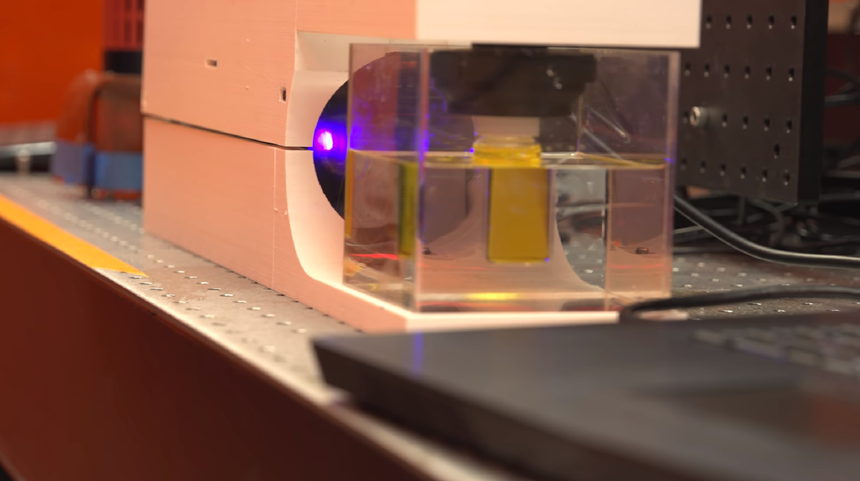

What the UC Berkeley development shares with Carbon is a process that focuses light at liquid resin to cure a desired solid shape from it. But where Carbon’s method is a continuing process of curing a changing cross-section of the part, the Berkeley device—which its creators have dubbed “the replicator,” after the Star Trek device that creates solid objects on demand—is able to solidify the entire part at once.

The process, called “Computed Axial Lithography” (CAL), begins with a 3D computer model of the desired object, from which are generated a series of light patterns. These patterns are projected from a standard video projector onto a clear cylinder-shaped container of a specially formulated light-sensitive resin. Unlike Carbon’s, this resin is sensitive to the normal spectrum of light rather than just the UV range. The system’s workability depends on controlling the amount of light needed to cure the resin at the optimal speed.

The container is on a motorized rotating base and the light patterns are synched to its rotation. The resin cures only in certain areas based on the light patterns. And after one complete revolution—taking from 30 to 120 seconds, depending on the object—a solid object matching the original computer model is taken from the container.

“Obviously there are a lot of subtleties to it—how you formulate the resin, and, above all, how you compute the images that are going to be projected, but the barrier to creating a very simple version of this tool is not that high,” says Hayden Taylor, UC Berkeley assistant professor of mechanical engineering. Taylor is senior author of a paper describing the printer in the journal Science.

Granted, as of yet, these aren’t very large parts. This first prototype system is limited to producing parts no larger than four inches in diameter. But the method enables some advantages.

Unlike most other printing methods, the system can print flexible items without the worry of deformation during the build. There is no need for in-process supports when building a shape such as an arch, as would be needed in layer-by-layer methods. It avoids the stair-step ridges on the surface that betray the individual layers of some printed objects. And the process generates practically no waste—heating the leftover, uncured resin in an oxygen atmosphere makes it reusable.

Perhaps of more value to manufacturers, the process can be used to print a part around an already existing piece of material—not an easy task when using other methods. This ability was demonstrated by forming a handle around a metal screwdriver shaft.

“The fact that you could take a metallic component or something from another manufacturing process and add on customizable geometry, I think that may change the way products are designed,” says Taylor.

RELATED CONTENT

-

Speed Metal

The grail of metal additive manufacturing is the ability to keep pace with full automotive production. The quest continues.

-

Additive @ Ford

Here’s a look at how additive technology is being thought of—and used— at Ford.

-

How GM Quickly Created Capacity for Mask Production

GM’s head of global manufacturing engineering talks about how a global team put mask production capacity on the floor in a week