Plate Buckling Analysis Made Simple

Designing thin-walled steel structures? Then GAS2.0 is for you

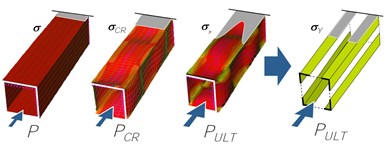

Speaking of creating components for automotive structures, Dr. Donald E. Malen, lecturer, Integrative Systems and Design, University of Michigan—who had spent 35 years at General Motors in automotive body structure design and analysis, and systems engineering, so he knows more than a little something about the topic—said, “Tall, thin wall sections can be very mass efficient. However, an additional failure mode that’s beyond yield is plate buckling. Classical section analysis doesn’t take that into account.”

So the American Iron and Steel Institute has developed a Windows-based system, GAS2.0, that can be readily used by design engineers, CAD operators and analysts, to determine plate buckling under load. And this is a light-weight system that can even be run on tablets.

The analysis process. (Image: AISI)

Malen noted that as buckling strength is based on material thickness and width, a simple answer to addressing plate buckling would be to increase thickness—but that would have a negative consequence on mass efficiency.

What It Does

The tool allows the analysis of steel structures—IGES and STEP CAD files can be readily entered into GAS2.0 or even simple sketches can be loaded—so that it can be readily seen where the design is not taking full advantage of the material. (This is looking at the yield of the effective section.)

The software includes 63 steel grades and additional steels can be loaded. Two types of analysis can be performed: nominal (classic area properties) and effective (axial or moment loading). Results can be shown graphically or in a tabular manner.

“Yield of effective section depends on section geometry, material yield and loading,” Malen said.

GAS2.0 allows this to be done either early in the design stage (thereby allowing the identification and mitigation of problems) or even later in the design process, before more detailed analyses (e.g., FEA) are performed.

Notably, GAS2.0 is available from the AISI Automotive Program without license fees.

RELATED CONTENT

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

.jpg;width=70;height=70;mode=crop)