On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.

#robotics

Welcome to the third edition of Gardner on Automotive, our weekly look at products, processes, people, and other topics that are, well, topical in the global auto industry. This week we look at electrification, which is sparking like mad in the industry. We’d like to ask you to do us a favor: forward this newsletter to a co-worker and ask them to subscribe.The more the merrier. Thanks, Gary S. Vasilash

This week On Automotive

- 2021 Volkswagen ID.4 First Edition

- Battery Recycling: VW’s new protocol

- AGVs As EVs

- Meanwhile, Over In Europe. . . Diesel still dominates

- About the Market: Are car buyers looking for EVs?

- Geared Up: Eaton’s gear architecture

- Kia’s Advanced Design Philosophy

///

2021 Volkswagen ID.4 First Edition: Oh, and It Happens to Be an EV

The VW ID.4. An electric vehicle that is simply a really good crossover. (Image: VW)

Bigger than the Beetles. “The most important vehicle for Volkswagen, honestly, since the launch of the Beetle.”—Scott Keogh, president and CEO, Volkswagen Group of America on the 2021 Volkswagen ID.4.

Volkswagen built 21,529,464 Beetles. Of course, that was over a 58-year run for the Type 1 (1945 to 2003). Odds are there won’t be an ID.4 going out of production in 2079.

But it goes to the point of what they are trying to achieve with the ID.4.

Volkswagen has a big plan for its EVs, as in having 70% of its EU sales being EVs by 2030 and more than 50% in the U.S. So the ID.4 will contribute to the millions of expected sales.

Crazy, Cool. And Normal. Keogh: “The trick to the ID.4 is that we’ve developed, designed and priced a vehicle to go after mainstream, compact SUVs, the RAV4 Honda CRV. We want to drive the adoption of electric vehicles. In order to do that you have to develop a crazy cool car and put it at great price. We’ve packaged the car like a Tiguan; the car drives like a Volkswagen Golf, and it has the personality and charisma of a Beetle. It is meeting the moment.”

They’re essentially saying: “This is a normal compact crossover.”

- The base MSRP is $39,995.

- There is a probable $7,500 Federal tax credit, which brings it down to $32,495.

- There is three years of free charging at Electrify America stations, which dot the country. So if the price of gasoline that one might pump for a crossover is $58 per month, over three years that’s $2,088. Subtracting that from the $32,495, the ID. 4 is $30,407.

- That price for a newly designed and engineered crossover—never mind what powers it—is certainly not out of the ordinary.

According to Kelley Blue Book, the average transaction price for a compact SUV/crossover in January 2021 was $30,557.

But It Is an EV. Here’s something that is original Beetle-like: The motor is in the back. It is an AC, permanent-magnet synchronous motor that generates 201 hp and 229 lb-ft of torque. It is mated to an 82-kWh lithium-ion battery pack.

Here’s the number you probably care about most: It has an EPA-estimated range of 250 miles.

Other Numbers You Care About:

- As in Level 1 charging. Your home outlet. Charges at ~3 miles per hour.

- Level 2 charging—what you’d get for a home install or most of the public chargers—goes from empty to full in 7.5 hours.

- Level 3—or DC fast charging, 125 kW (available at some Electrify America stations, incidentally)—charges the battery from 5% to 80% in 38 minutes.

Obligatory Impressions. VW has done some clever things for the ID.4. Like mounting a 5.3-inch digital screen (called the “ID.Cockpit”) on top of the steering column. It contains information like speed and amount of battery life. No matter how you adjust the position of the wheel, it is always visible. And that info is good to know.

Yes, there is also a larger center screen (depending on trim, from 10 to 12 inches) for purposes of infotainment.

There are plenty of haptic “buttons” (touch the flat surface and it “feels” like you’ve pushed a button) and surfaces you swipe (e.g., to adjust the temp).

Overall, the usefulness of the controls and the cabin indicate lots of attention to what people actually do in their vehicles, which is a good thing.

Final Thought. The ID.4 is a well-executed compact crossover. It happens to be an electric vehicle.

///

And While on the Subject of VW EVs. . .

VW plans to build millions of EVs, which means there will be millions of EV batteries that, at some point, are going to have to be dealt with. So the company has developed a recycling protocol. (Image: VW)

If you’re going to be making millions of EVs, at some point you’re going to end up with lots of used batteries.

Those Materials Aren’t Cheap. In addition to which, with constituents like lithium and cobalt, you’re not going to want to stick these in a landfill.

Listen: “We know from many years of research that recycled battery raw materials are just as efficient as new ones,” says Mark Möller, Head of Technical Development & E-Mobility Business Unit at Volkswagen Group Components.

Pilot Processing Plant. VW has established its first EV battery recycling plant. It is in Salzgitter, Germany. It can handle about 3,600 battery packs per year. Presumably (1) the volume meets the current need and (2) they can both scale and further automate the operation.

The Process. After they make sure the electricity is drained, the battery pack is disassembled. Modules are removed and shredded. This results in a “damp mass of large granules and battery chemicals.” This is dried and the liquid electrolyte pumped out.

An extraction process removes “black powder” consisting of lithium, manganese, cobalt and graphite (a.k.a., the good stuff).

Magnetic materials are taken out of the mix, then non-magnetic.

The output is bagged: plastics in one, mixed aluminum and copper in another, and then the valuable black powder.

High Efficiency. VW calculates it can recapture and then reuse as much as 95% of the materials. From a typical 880-pound battery pack, they’re reclaiming about 220 pounds of electrode minerals.

Current battery recycling approaches only recover about 60% of the valuable materials.

///

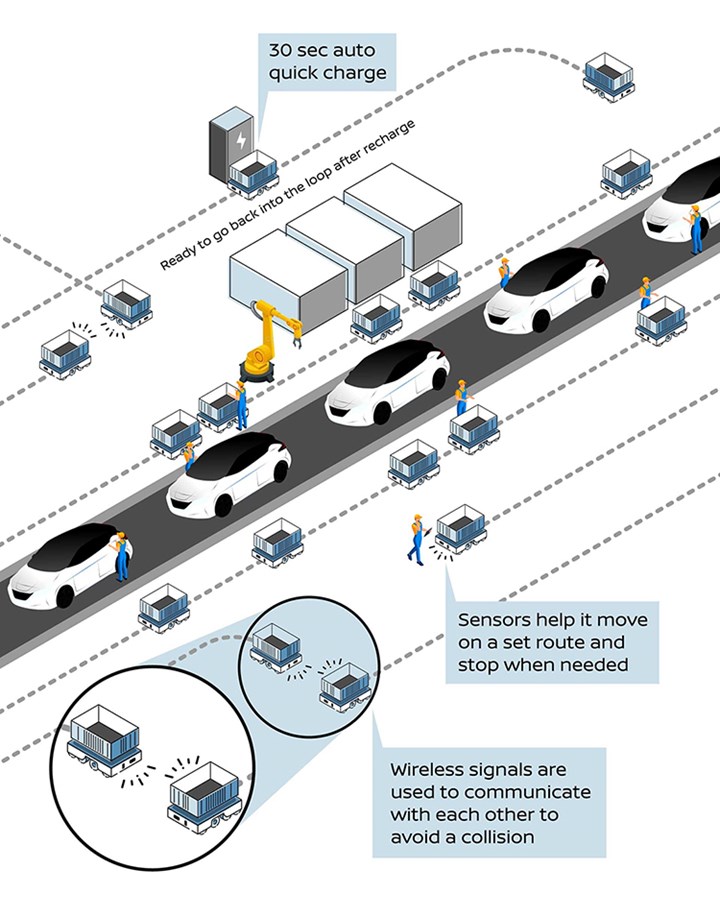

AGVs As EVs

By using batteries from LEAFs that have ended their automotive use in AGVs, factory material handling can be improved. (Image: Nissan)

Nissan officially launched the LEAF electric vehicle on December 3, 2010. More than 500,000 have been sold, since.

Before Nissan launched the LEAF, it partnered with Sumitomo Corp. to establish 4R Energy Corp., with the focus being on LEAF batteries and the “Rs” standing for:

- Refabricate

- Recycle

- Resell

- Reuse

Nissan has some 4,000 automated guided vehicles (AGVs) rolling through its factories.

Modules to Packs. Earlier last decade 4R had the idea to take three of the 48 modules that made up the 24-kWh lithium-ion battery for the first gen LEAF and use them for AGVs.

Now they’re using entire packs that are no longer sufficient to power a car, but just fine for an AGV.

What’s more, this approach is more efficient: before workers had to remove the three modules to recharge them. With the full pack, the recharging happens much faster—in less than a minute.

Nothing New. AGVs have long been powered by batteries. Often of the lead-acid variety.

According to Nissan, while the lead-acid batteries have a life span in the AGV application of not longer than two years, the lithium-ion batteries will be good for about eight years.

///

Meanwhile, Over In Europe. . .

Let’s Not Get Too Carried Away: Although indicators show that the EU is embracing EVs more rapidly than the U.S., when it comes to trucks in the EU, there is a fuel that remains dominant: Diesel.

Yes, diesel.

According to the European Automobile Manufacturers Association (ACEA), in 2020 diesel-powered trucks accounted for 96.4% of all registrations.

Plugs? “Electrically-chargeable vehicles” accounted for just 0.5% of all trucks registered in 2020.

To put that into perspective, that means 1,059 trucks.

It Could Have Been Worse: Hybrid trucks saw a gain of 31.5% compared with 2019—yet that total number is 351 units. (Always check the base something is being compared with.)

Gasoline (a.k.a., petrol) fueled trucks: 210 units.

Both hybrid and ICE trucks have 0.1% of the market.

///

About the Market

Data Point: The J.D. Power 2021 U.S. Electric Vehicle Experience (EVX) Ownership Study finds:

- Two out of 10 shoppers are “seriously considering” an EV in the near future

- Two out of 10 shoppers are “strongly against considering” an EV

- Six out of 10 shoppers shrug when it comes to EVs

Why would someone be “strongly against considering” anything?

///

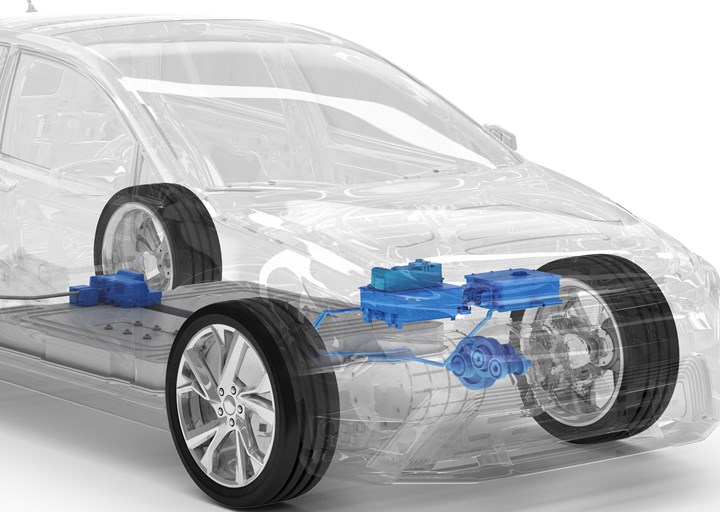

Geared Up

Eaton is using its know-how in producing systems for ICEs to EVs, achieving improved efficiencies and dealing with issues like NVH. (Image: Eaton)

Eaton has extensive capability—design, engineering, manufacturing—when it comes to producing gears and things that gear sets go into, like transmissions.

A Different RQ: But let’s face it: EVs have vastly simplified transmissions compared with ICE vehicles.

So what does a company like Eaton do?

We asked.

Anthony Cronin, director, EV gearing, Eaton Vehicle Group: “When we look at a gear architecture for an EV, it isn’t just optimize the surface finishing and machining. Eaton has developed a system to look at the overall gearing system and looking at the microgeometry along the tooth profile and tooth surface finish, the number of teeth and gear blank geometry, the angles, ratios and center line. What you end up with is an optimized solution.”

Marco Oliviera, advanced manufacturing engineer manager, Eaton’s Vehicle Group: “The technology to make the gear remains the same. Many times we use the same gear cutting machine but the tooling and fixtures are different.”

///

Kia’s Advanced Design Philosophy

The Kia EV6 is the first example of the company’s new design philosophy. Clearly, vehicles with that kind of styling are appealing regardless of what the underlying propulsion system is. (Image: Kia)

“Opposites United”

That’s the name of the design philosophy that Kia designers will use to develop new vehicles, like the EV6, that’s based on the brands E-GMP: Electric-Global Modular Platform.

About the EV6 Design: “EV6, as the first dedicated Kia EV, is a showcase of human-centered, progressive design and electrified power. We strongly believe EV6 is a compelling and relevant model for the new EV market. With EV6 we aimed to create a distinctive, impactful design by using a combination of sophisticated, high-tech features on pure and rich volumes, while providing a unique space as a futuristic EV.”-- said Karim Habib, Kia Senior Vice President and Head of Global Design Center.

RELATED CONTENT

-

Cobots: 14 Things You Need to Know

What jobs do cobots do well? How is a cobot programmed? What’s the ROI? We asked these questions and more to four of the leading suppliers of cobots.

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

-

GM Is Down with Diesels

General Motors is one company that is clearly embracing the diesel engine.

.jpg;width=70;height=70;mode=crop)