Solid Edge Brings Divergent Modeling Worlds Together

This new software suite allows the development of “beautiful models ready for production.” What more can you ask for?

“The dirty little secret” in computer-aided design (CAD), says Dan Staples, Siemens PLM Software vice president of product development, are the “challenges” in making generative design, additive manufacturing (AM) and reverse engineering “a cohesive whole.” The problem revolves around faceted (mesh) versus B-rep (feature-based) models, and that never the twain shall meet—without some modern-day technology.

That technology, within the latest version of Solid Edge, nicknamed “ST10,” from Siemens PLM (plm.automation.siemens.com/en/products/solid-edge/st10/), is called “convergent modeling.” This “secret sauce,” a form of hybrid modeling, lets designers and engineers use mesh models as if they were B-rep models. That, along with Siemens PLM synchronous technology, which combines direct modeling with parametric design, makes ST10 a modern-day design tool.

Introducing convergent modeling

Generative modeling lets designers create interesting designs. These designs are connected together into a mesh. Reverse engineering lets users scan objects and get a series or cloud of points. Algorithms turn those points into a triangulated mesh. AM has been based on triangulated meshes since its introduction.

Because these three operations use mesh-based geometries, a problem exists: Most design engineers work in CAD systems that create boundary representation (B-rep) models, which are feature-based solid models. B-rep, explains Staples, uses cylinders, planes, cones and other objects to create a design. Faceted modeling doesn’t; its designs use a mesh.

Given modeling realities, producing a great generative design or a part design from reverse engineering becomes less than “seamless” when it’s time to modify the design—using a CAD system based on B-reps. Conversely, continues Staples, converting 3D scans to final designs is not hard, but people can spend days surfacing those designs. Unless they’re using B-rep CAD.

Convergent modeling solves all that by combining B-rep solids and facet models together. Explains Staples, “You can have B-rep data or mesh-based data. The data can co-exist. You can do Boolean operations between them. You can do feature-based modeling on the mesh models. The user interaction is so seamless, you might think you’re working on a b-rep model when in fact you’re not.”

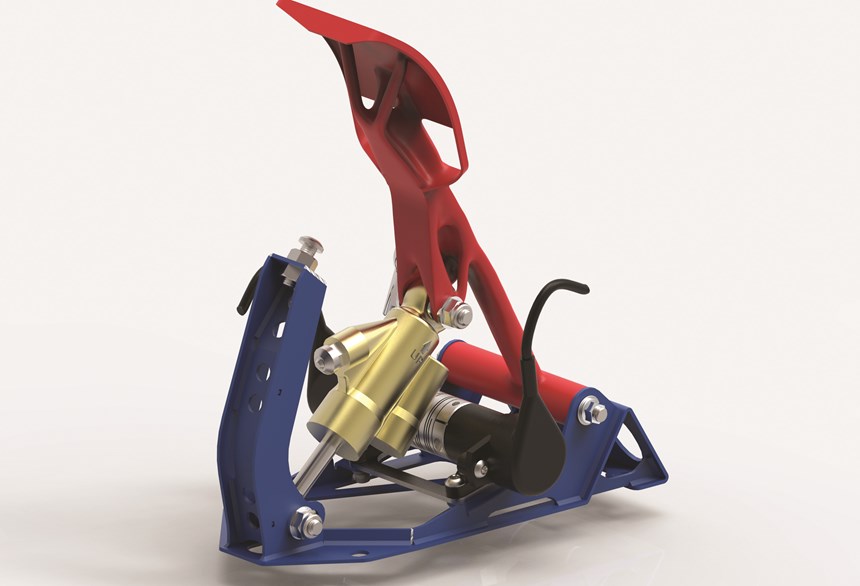

In generative design, says Staples, engineers typically get “a really cruddy looking thing. It tells you where to put material; then you have to do all the work modeling the part.” With ST10, engineers can create organically shaped “beautiful models ready for production” by essentially performing feature-based modeling on mesh-based parts. On the other hand, when applying generative design techniques in traditional reverse engineering, users have to take the scanned model into a B-rep model. ST10 eliminates having to choose what CAD method to use. Users, says Staples, “can do all sorts of feature-based model directly on that data.”

Users can also extract surfaces from mesh data into planar or cylindrical surfaces (i.e., B-rep models). With synchronous technology, users can work directly on the surfaces of 3D scanned mesh geometries natively, thereby eliminating the need—and time, energy and money—for reverse-modeling.

Put together as it is in ST10—direct, facet and parametric modeling—there’s “no time-consuming, error-prone conversions. You don't have to spend days reverse-modeling over mesh data. And if you already have an awesome ready-to-print model, you can still add/subtract features,” explains Staples. Plus, says John Fox, Siemens PLM vice president of marketing, ST10 replaces a number of legacy tools for importing, exporting and modifying generative designs, scanned models, or performing topology optimization, thereby eliminating several large bottlenecks.

The best of the rest

ST10 has several other new features. It includes a new, fully embedded computational fluid dynamics (CFD) simulation and analysis tool for investigating fluid flows and heat transfers. Also, “If you’re a Solid Edge customer, you get Catchbook in the main package,” explains Fox. This way, a designer can sketch a drawing in any mobile device, export that drawing to ST10, then go from there.

On the computer-aided manufacturing (CAM) side, Solid Edge CAM (formerly CAM Express) now includes Siemens’s own adaptive milling algorithms, which generate CNC-based cutting programs to increase tool life by using more of a tool’s flute length. Post processing, usually a costly and time-consuming process, is aided by PostHub, a cloud-based interface to access post processors. Users can filter the available post processors by machine or by mill writer (if somebody good at writing post processors for a particular machine is known). Users can see several try-before-you-buy post processors, as well as post processors provided by Siemens for free.

ST10 introduces Siemens PLM’s entry into technical publications and interactive technical documentation. Solid Edge Illustrations (formerly QuadriSpace Publisher3D) creates detailed illustrations, such as exploding views, and publishes those to webpages—directly from Solid Edge geometry, and product and manufacturing (PMI) annotations. Solid Edge Documentation (formerly QuadriSpace Pages3D) is a more comprehensive product for creating customizable, multi-page documents, such as work instructions, interactive part catalogs, product manuals and “a lot more than you can do with your standard word processor,” says Oliver Duncan, product manager of Solid Edge Design Products.

ST10 includes built-in data management functionality, such as filtering for new or newly available parts in assemblies, enhanced revision management, access to component revision histories and associated drawings, automatic document numbering and replacing obsoleted components, full text search in drawings, and duplicate file detection. Design Manager is basically a hub for performing data management housekeeping tasks. In it, users can move, rename, revise data, find data duplicates and other tasks.

All that’s in ST10 lends credence to something Fox says: “Conceptually, manufacturing, data management, design and tech pubs are all part of the portfolio. Solid Edge is CAD, yes, but it’s really a product development portfolio tool.”

RELATED CONTENT

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

-

TRW Multi-Axis Acceleration Sensors Developed

Admittedly, this appears to be nothing more than a plastic molded part with an inserted bolt-shaped metal component.