The Latest CAD System Offers a Triple Play

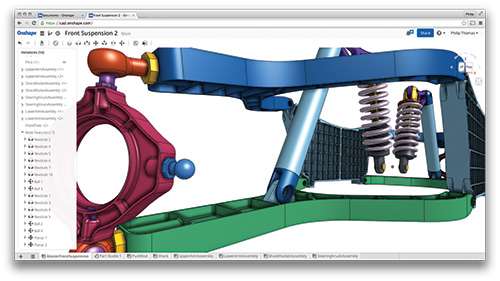

Onshape combines mobility, collaboration and integral product data management with 3D CAD— at a “petty cash” price, if free isn’t good enough.

For an idea of how computer-aided design (CAD) is evolving, look at Onshape from Onshape, Inc. (formerly Belmont Technologies; onshape.com). Onshape combines cloud technology, simultaneous access and data management with 3D mechanical CAD. Among the benefits cited by the company are the abilities for people to collaborate via any web browser, phone or tablet without licensing or file copying concerns and to work without a separate product data management (PDM) system. Collaboration is built into the core of Onshape.

Pretty strong set of claims, yes? Realize that Onshape comes from many of the same folks who founded SolidWorks (and before that, worked at Computervision).

Bring in the cloud

Both the Onshape CAD program and the associated design data are stored on the cloud as “smart objects,” not as files on a disk. They are arranged in “Onshape Documents,” which are project-level containers that include the relevant models, drawings and data.

This software as a service (SaaS) winds up delivering what’s described as “workstation-level performance” on entry-level computers, phones, and tablets. This real-time performance is often faster than desktop CAD because the software is running on a huge number of cloud-based compute cores—far, far more cores than in a desktop computer, and certainly more than in any mobile device.

Onshape runs on every computer device on the market today: Linux, Mac and Windows; Android, Chrome OS and iOS; Chrome, Firefox and Safari (though not Microsoft Internet Explorer); Chromebook, desktop, laptop, tablet and smartphone. Even on a phone or tablet, people can do all of their CAD work—not just view and markup. For mobile devices, Onshape created a “precise touch-screen interface that replaces the traditional keyboard and mouse interactions. Every CAD command and action is controlled with a swipe of your finger,” says Onshape founder and chairman of the board, Jon Hirschtick. “You’re able to sketch, extrude, fillet, shell, create 3D models, edit their shape and size and put them into assemblies.”

One caveat to all this: Onshape can only be used when connected to the Internet. However, says John McEleney, CEO and cofounder, “If your connection is good enough to stream Netflix, it’s good enough to use Onshape.”

Making collaboration easier

Real-time design collaboration is a data management problem. That’s what PDM (and PLM) is supposed to solve. Onshape uses a different approach to make collaboration possible. “The CAD system and CAD data live in one place in the cloud, and are never copied anywhere. Everyone on a design team sees and works on the same master CAD data at all times, avoiding confusing checkouts, file copies and overwriting each other’s work,” explains Hirschtick.

Instead of copying data, designers create separate “branches” of a design when modifying a design. Onshape stores these variations (branches) within a single document. At any time, people can merge branches as the design progresses, which saves design rework when merging design ideas.

In Onshape, data access is controlled by the document’s owner, while version control is built-in so that individual users can create a protected state for their documents at any time. Because conventional relational databases fall apart when merging multiple datasets, such as part designs and changes, Onshape uses an open-source, document-oriented database to store all design metrics—every step, entry, modification, tweak and operation performed on a solid model as it progresses to completion. Designers can undo design changes back to the very start of the design if needed. Designers can also delete, revise, and merge individual design operations. Along the way, Onshape handles data management tasks such as revision labels, part numbers and model status (e.g., in-progress and released).

Onshape natively supports import/export from a variety of CAD systems, including Autodesk Autocad and Inventor, Dassault Catia and SolidWorks, PTC Creo, Siemens PLM Software JT and neutral formats such as ACIS, DXF, IGES, Parasolid, SAT, STEP and STL. Users can control access levels, grant and revoke permissions, and control the versions of the native CAD files, or translate those third-party CAD files into Onshape’s native format for viewing and editing. Onshape’s direct editing tools let users modify the translated CAD files.

Another caveat: Users can’t print directly from Onshape. Instead, they can export drawings to DWG, DXF or PDF and print from there.

Oh, and CAD, too

At its core, Onshape is a mechanical 3D CAD system. It uses the Parasolid modeling kernel (the same kernel in SolidWorks and Siemens NX), and it has parametric and direct-modeling functions for part and assembly modeling. The program also has a dedicated tool for creating 2D drawings (standard, auxiliary, projected, and sectional views) from the 3D models. Drawing templates that conform to ANSI and ISO standards are available to get users started on new designs.

The Onshape App Store helps users who need more than just CAD. Onshape add-ons come in three flavors: integrated cloud apps, connected cloud apps, and connected desktop apps (think traditional desktop programs). To date, add-on categories include analysis, computer-aided manufacturing, content (such as automated part selection), visualization/rendering, 3D printing, data management, utilities and import/export.

There are three subscription levels, all providing the same CAD functionality. The Free subscription comes with 5 GB of online storage for any number of public documents and for up to 10 private documents. (Public documents are available for viewing and copying, but not editing.) The Professional ($100 per user per month) and the Enterprise subscriptions offer unlimited storage for an unlimited number of public and private documents. The Enterprise level, which is priced depending on corporate user, is for large Onshape deployments requiring advanced design control and reporting.

RELATED CONTENT

-

Choosing the Right Fasteners for Automotive

PennEngineering makes hundreds of different fasteners for the automotive industry with standard and custom products as well as automated assembly solutions. Discover how they’re used and how to select the right one. (Sponsored Content)

-

GM Is Down with Diesels

General Motors is one company that is clearly embracing the diesel engine.

-

Cobots: 14 Things You Need to Know

What jobs do cobots do well? How is a cobot programmed? What’s the ROI? We asked these questions and more to four of the leading suppliers of cobots.