Tech: NVIDIA’s Level 2 system; 3D sees the light; A Fish-like Camera

NVIDIA’s Level 2 system has Conti, ZF on board. A 3D solution that sees the light and could be nearly as fast. A camera that sees like the fishes. Toyota aims to smarten China’s car industry.

NVIDIA’s Level 2 system has Conti, ZF on board

Two years ago, Continental (continental-automotive.com) and ZF (zf.com) – fierce rival suppliers in most auto domains – agreed to work together with NVIDIA (www.nvidia.com) to advance a commercial automated driver system. Two years later, the trio of companies returned to the 2019 CES to say that system will be commercially available in 2020.

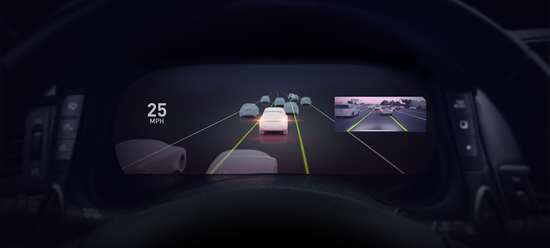

Called NVIDIA DRIVE AutoPilot, the Level 2+ system pulls together AI technologies to boost the features everyone expects in automated driving, namely smart cockpit assistance and visualization, but in a way the companies say will surpass contemporary ADAS offerings.

Beyond the basic adaptive cruise control, lane keeping and automatic emergency braking features, the system is billed to handle situations where lanes split or merge, and safely perform lane changes, while also monitoring driver actions in the cabin.

The DRIVE AutoPilot mates with the NVIDIA Xavier system-on-a-chip processors and NVIDIA DRIVE software. The combo is intended to process several deep neural networks to perceive its surroundings, which are fed from a 360-degree camera.

Continental is using the system to develop an affordable automated driving architecture and blend it with its existing lineup of radar, lidar, camera and automated driving control unit technology. ZF meanwhile will use it in its ProAI modular hardware concept and open software architecture.

A 3D solution that sees the light and could be nearly as fast

Despite its promise, 3D printing as currently practiced isn’t making a substantial dent on manufacturing time and costs, according to researchers at the University of Michigan who’ve come up with something that’s potentially much faster.

“Using conventional approaches, [efficiency is] not really attainable unless you have hundreds of machines,” said Timothy Scott, U-M associate professor of chemical engineering who co-led the development of the new approach.

That newly released technique, which lifts shapes from a vat of liquid and uses two lights to control where the resin hardens, is challenging tried-and-true methods in 3D printing. But this isn’t a mere academic revelation; its creators also claim it’s up to 100 times faster than traditional additive manufacturing.

The U-M technique uses thicker resins and relies on a larger platform to halt solidification. Instead of creating a series of one or two-dimensional cross sections, the U-M researchers found they can make a 3D bas-relief (or carving a design into a surface) in a single shot. And by using two lights to control where the resin hardens and where it remains fluid, the team was able to solidify it into more complex patterns. Their printing demonstrations include a lattice, a toy boat and, unsurprisingly, a block M – the university logo.

Their process also alters the chemistry equation. In conventional systems, the resin hardens when exposed to light, the result of a photoactivator. The U-M solution uses a resin that also has a photoinhibitor, which responds to a different wavelength of light, allowing the two kinds of light to harden the resin at specific points.

The discovery is the subject of three patent filings and a startup company that Scott plans to launch.

A camera that sees like the fishes

Reportedly, it’s very hard to sneak up on a mantis shrimp. It has tiny photoreceptors that detect polarized light, allowing it to perceive very dark and very bright objects in its field of view, discerning predator from prey in the murky ocean waters it calls home. That’s not just a bit of ichthyology trivia, but the inspiration for a new type of camera that mimics the shrimp’s peepers.

The new camera has a dynamic range, or a measure of the lightest and the darkest areas it can capture simultaneously, that’s approximately 10,000 times higher than contemporary commercial cameras, researchers at the University of Illinois at Urbana-Champaign said. Such a range could help self-driving visualize conditions, such as transitioning from a dark tunnel into bright sunlight, more acutely.

"In a recent crash involving a self-driving car, the car failed to detect a semi-truck because its color and light intensity blended with that of the sky in the background," says research team leader Viktor Gruev.

The researchers tweaked the way the camera's photodiodes convert light into an electrical current. Instead of operating the photodiodes in “reverse bias mode,” which is traditionally used for imaging, the researchers used forward bias mode. For the polarization sensitivity, the researchers essentially copied the way the mantis shrimp integrates polarized light detection into its photoreceptors by depositing nanomaterials directly onto the surface of the imaging chip that contained photodiodes.

"These nanomaterials essentially act as polarization filters at the pixel level to detect polarization in the same way that the mantis shrimp sees polarization," said Gruev.

The researchers describe the new camera in the Optical Society journal, Optica. They note the camera could be mass-produced for as little as $10 apiece.

Toyota aims to smarten China’s car industry

As partnership announcements go, Toyota’s recent partnership with Panasonic for joint venture to research, manufacture and sell batteries for EVs, was a pretty big one. Toyota will take a 51 percent stake and Panasonic will have a 49 percent in the joint venture, which will be up and running by 2020 the companies say.

But in another, lesser known, strategic agreement Toyota signed with INGDAN.com (en.ingdan.com) to create a platform for developing and deploying a host of products and applications for the Chinese smart car industry.

INGDAN.com is a subsidiary of Cogobuy Group, an e-commerce company for the electronic manufacturing industry that’s focused on AI and the Internet of Things tech across China. Cogobuy says the partnership will give it access to Japanese auto tech suppliers while Toyota will have mutual introductions to Cogobuy customers along the industrial supply chain.

RELATED CONTENT

-

GM Develops a New Electrical Platform

GM engineers create a better electrical architecture that can handle the ever-increasing needs of vehicle systems

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.