Eaton Accelerates Use of Industry 4.0 Tech in Wake of COVID-19

Making the most of emerging manufacturing technologies to improve efficiencies during the pandemic

#robotics #iot

Like most manufacturing companies, Eaton’s Vehicle Group implemented a variety of safety protocols as it reopened its facilities after COVID-19 restrictions were lifted. The effort, which was led by a global task force of senior executives, included post-lockdown staples such as temperature scanning, masks, intensive cleaning, optimized logistics and social distancing.

But Eaton also used the situation to evaluate several new technologies to see how they could best be used to bolster safety and improve efficiencies. As a result, the company has accelerated and refined the use of:

- Augmented reality tools

- Additive manufacturing

- Cobots

- Data sharing and analysis

- Digital simulation

Safety First

Safety was the primary driver, stresses Joao Faria, the Vehicle Group’s president. “We did a lot of benchmarking, then developed our own protocols that exceed government requirements in all countries.”

At the same time, he says, it was important to leverage new technologies and integrate them into proven processes to quickly ramp up production, while ensuring that quality, cost and performance metrics were met.

Making it work was a massive undertaking. The Vehicle Group, which produces various powertrain and drivetrain products—including electrified systems—plastic components, fluid conveyance, emission controls and lubricants, employs some 15,000 people at 49 facilities worldwide.

Seeing is Believing

One of the first tools Eaton began to use during the lockdown phase of the pandemic was Microsoft’s HoloLens 2 augmented reality goggles. The technology, which lets remote users view and interact with 3D images of locations and products, enabled engineering teams to continue to do their jobs from home.

Eaton production manager Edinaldo Fancio utilizes Microsoft’s HoloLens 2 to conduct a layered process audit. (Images: Eaton)

Engineers in multiple locations work together in real time to analyze and make changes to parts and processes. The technology also is being used for customer reviews and approvals during development and certification processes, without the need for on-site visits, including monitoring individual tasks as needed.

The technology is proving even more beneficial than Eaton expected, Faria says, noting that all Vehicle Group sites now have access to the HoloLens goggles. “We’ve broken some barriers on effectiveness and how people can work together when they’re apart.”

The supplier also is using augmented reality technologies to help train engineers and assembly workers on new equipment. In the past, such training required instructors to travel in person to various sites.

3D-Printing

Eaton also is accelerating the use of additive manufacturing systems in the wake of COVID-19.

Eaton engineer inspects a 3D-printed part

The company says 3D printers can improve safety, quality and efficiency by designing and producing tools, gauges and poke-yokes (error-proofing systems) in-house for both polymer and metal materials. This results in faster turnaround times, greater design customization and reduced costs, according to the supplier.

For example, Eaton says lead times can be condensed from weeks to days, while costs can be reduced from thousands of dollars to a few hundred.

Co-Boting

Part of the new safety protocols requires employees to maintain 6-ft distances between each other and/or use personal protection equipment. Such distancing can be challenging in traditional factories and could require significant changes to the physical layout of workstations.

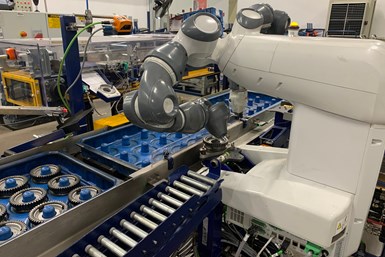

A cobot completes sub-assembly operations on synchro transmission components.

But Faria says Eaton has been able to make better use of advanced robots to aid the process and minimize the need for major changes. The strategy includes introducing autonomous and collaborative robots (cobots), which interact with humans in a shared space or in close proximity, to handle complex and repetitive tasks. This results in improved consistency and accuracy, according to Faria.

Eaton also is increasing the use of automated guided vehicles (AGVs) and autonomous mobile robots in place of forklifts and other human-operated transport machinery. In addition to improving the flow of materials through a facility, the supplier says such equipment boosts safety, lowers costs and allows for social distancing.

Advanced robots can be designed and installed in as little as 3-6 months, according to Faria. He says cobots are especially useful in areas that require high-speed, repetitive movements and/or the handling of heavy parts, such as commercial vehicle transmissions.

Most applications currently simulate the use of one arm. But Eaton also is developing a two-armed cobot to improve efficiency and quality for more complex applications.

Big Data

The Vehicle Group also is interconnecting plant systems and machines to collect, analyze and report real-time information, which the company says optimizes plant floor management and helps workers identify and correct potential problems faster.

Sharing so-called big data throughout the manufacturing process can reduce inventory requirements and labor costs (direct and indirect), improve maintenance and repair efficiencies, and increase performance and quality, Eaton claims.

What’s Next?

“As the industry continues to adjust to new requirements, I’m confident that Eaton will see lasting improvements from the use of new technologies,” Faria says. Some of the paybacks, he adds, could yield significant double-digit gains in efficiency and cost reductions and pay for themselves in two years or less.

But it won’t be an easy, one-size-fits all fix. “The key for us is driven by business cases for each facility and process,” Faira explains. “It’s an evolving process. There will be further advance in tools, technologies and processes, and all of the pieces need to fit together. It’s a journey.”

RELATED CONTENT

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

-

On Electric Pickups, Flying Taxis, and Auto Industry Transformation

Ford goes for vertical integration, DENSO and Honeywell take to the skies, how suppliers feel about their customers, how vehicle customers feel about shopping, and insights from a software exec

-

Plastics: The Tortoise and the Hare

Plastic may not be in the news as much as some automotive materials these days, but its gram-by-gram assimilation could accelerate dramatically.