Nexteer Puts 3D Printers to Work in Fight Against COVID-19

Supplier ramps up production of personal protection equipment in Michigan and Poland.

Another automotive supplier is stepping up to help combat the global coronavirus pandemic.

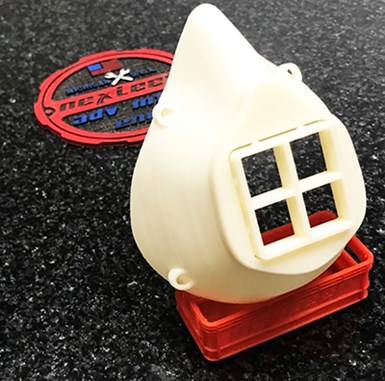

(Image: Nexteer)

Nexteer Automotive, which specializes in steering, driveline and advanced safety systems, is using 3D printers at its manufacturing plants in Michigan and Poland to make personal protection equipment for local medical professionals.

Making Masks in Michigan

At one of its facilities in Saginaw, Mich., Nexteer has begun making plastic face masks after developing prototypes that were reviewed by local medical professionals.

Two sizes are being produced to better accommodate different users, according to the supplier. The masks then are sent to the Michigan Health Improvement Alliance to be fitted with filter material and elastic for ear straps.

Personal protection face mask produced at Nexteer’s Saginaw plant.

Nexteer initially aims to produce about 50 masks per day. But it already is looking for ways to boost capacity. This includes teaming with Mayer Tool & Engineering to convert an injection molding machine at another Saginaw facility, which the company says could produce as many as 1,000 medical-grade plastic masks per day. Nexteer is working with resin supplier PolyOne to provide the materials necessary to manufacture the face masks.

Quick Response in Poland

Nexteer says engineers at its facility in Tychy, Poland, began making headbands for face shields just two days after undertaking the initiative. The team is producing about 100 of the devices per day with 3D printers that typically are used to build prototype steering systems.

Nexteer engineering team in Tychy, Poland.

The headbands are strapped to face shields provided by another company. Nexteer is working with the city’s municipal office to distribute the complete units to local doctors and paramedics.

Building on a History of Support

Nexteer, whose origins date back to 1906, has a long history of transforming itself during economic and societal hardships. During World War II, when it operated as the Steering Gear Div. of General Motors, the company produced M1 Carbine military rifles.

Now the supplier is part of the so-called Arsenal of Health that has mobilized in response to the coronavirus pandemic.

“Around the world, our Nexteer team consists of smart, passionate problem solvers, and I’m so proud of how our team members have found creative solutions to help our local communities with much needed medical supplies,” Robin Milavec, Nexteer’s chief technology and strategy officer, said in a statement. “We will continue to work with local medical and government partners, as well as our suppliers, to provide much-needed face masks and shields to help the brave medical teams on the frontlines fighting the COVID-19 pandemic.”

Future COVID-19 initiatives could include partnering with automakers to produce other PPE systems and medical equipment. Nexteer says it also will share details about its current programs in Saginaw and Tychy to help other companies ramp up their own production.

RELATED CONTENT

-

Cobots: 14 Things You Need to Know

What jobs do cobots do well? How is a cobot programmed? What’s the ROI? We asked these questions and more to four of the leading suppliers of cobots.

-

Mustang Changes for 2018

On Tuesday Ford unveiled—using the social media channels of actor Dwayne Johnson (this has got to unnerve some of the auto buff book editors)—the 2018 Mustang, which has undergone some modifications: under the hood (the 3.7-liter V6 is giving way to a 2.3-liter EcoBoost four, and a 10-speed automatic is available), on the dash (a 12-inch, all-digital LCD screen is available for the dashboard), at the tires (12 wheel choices), on the chassis (MagneRide damper technology is being offered with the Mustang Performance Package), and on the exterior (three new paint colors). And while on the subject of the exterior, there are some notable changes—a lower, remodeled hood, repositioned hood vents, new upper and lower front grilles, LED front lights, revised LED taillamps, new rear bumper and fascia.

-

On Fuel Cells, Battery Enclosures, and Lucid Air

A skateboard for fuel cells, building a better battery enclosure, what ADAS does, a big engine for boats, the curious case of lean production, what drivers think, and why Lucid is remarkable