On Audi Sport, Aesthetic of Machinery, and New Manufacturers

Audi has had an innovative approach to racing, and its Dakar hybrid is no different. A look at designs from Maybach, Morgan and Pininfarina. Foxconn is serious about automotive manufacturing. KPMG’s survey reveals the viability of going “asset-light.” And a new vehicular automotive display will put you in the metaverse.

Audi’s Electrified Approach to Desert Racing

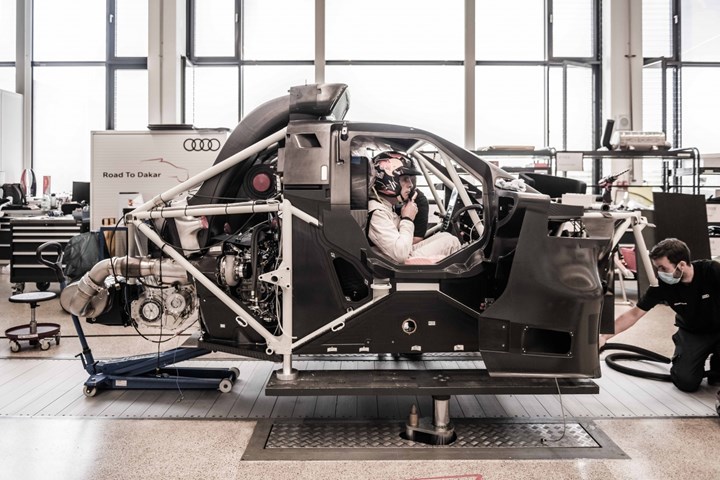

Assembling the hybrid that will be campaigned during the 2022 Dakar Rally. (Image: Audi)

The new year will see the start of the legendary Dakar Rally which, its name notwithstanding, will be held in Saudi Arabia, not Senegal.

One of the interesting teams is that of Audi Sport. It is campaigning an Audi RS Q e-tron rally car.

Yes, a highly electrified vehicle will go blasting through the sands of the Empty Quarter.

Audi wants to be the first to put a hybrid out in Rub' Al Khali.

Hybrid setup

The electric drive train for the vehicle consists of two motor-generator units (MGUs)—one each on the front and rear axles. These are the MGUs that were used in the 2021 Audi e-tron FE07 Formula E car.

There is a third, identical MGU. This one works in combination with a TSFI engine that is used in the Audi DTM (Deutsche Tourenwagen Masters) touring car racing series.

The engine and the third MGU are used to charge the battery while driving.

After all, it is not like there are charging stations out on the course.

The high-voltage battery—which weighs about 370 kg and has a capacity of approximately 50 kWh—was specifically developed for the race. Thermal management is a key consideration for an Audi e-tron that you could have in your driveway. And it probably doesn’t get as hot in your driveway as it will in the Saudi desert.

The vehicle build

Structurally, in order to stay within the rally regulations the frame, a tubular frame in this execution, must be made out of metal.

So Audi opted for a steel alloyed with chromium, molybdenum and vanadium (CrMoV) that is ordinarily used in the aerospace industry.

But then wrapped around the frame and used throughout the vehicle are components made of a variety of composite materials, such as carbon fiber reinforced plastic (CFRP), Kevlar, and Zylon, a high-performance synthetic fiber with an extremely high tensile strength.

The underbody is an area of particular concern, given that there is all manner of abuse from rocks and ramps and jumps and landings.

So the rally vehicle has a multilayer underbody that is 54 mm thick. There is aluminum plate on the bottom, then a foam material. Above that are CFRP structures that house the high-voltage system. The design is such that if the CFRP sandwich material is crushed as a result of a day’s racing it can be readily replaced.

Why?

“The quattro was a gamechanger for the World Rally Championship. Audi was the first brand to win the Le Mans 24 Hours with an electrified drivetrain. Now, we want to usher in a new era at the Dakar Rally, while testing and further developing our e-tron technology under extreme conditions,” says Julius Seebach, Managing Director of Audi Sport GmbH and responsible for motorsport at Audi.

“Extreme” is probably an understatement.

///

Maybach in the Wilds (Conceptually Speaking)

Probably not what you imagine a Maybach to be. Which is probably the point. (Image: Mercedes)

While on the subject of German vehicles from luxury marques that are meant for off-road adventures. . .

Mercedes-Benz worked with recently deceased fashion designer and artist Virgil Abloh on a concept vehicle, project MAYBACH.

Abloh and Gorden Wagener, chief design officer of Daimler AG, worked to create something that was 180 from the uber-urban character of a Maybach.

The result is a two-seat, off-road, battery-electric Grand Touring vehicle that is nearly 20-feet long.

Important to note: the designers were “untethered by production requirements.”

///

Morgan and the Aesthetic of Machinery

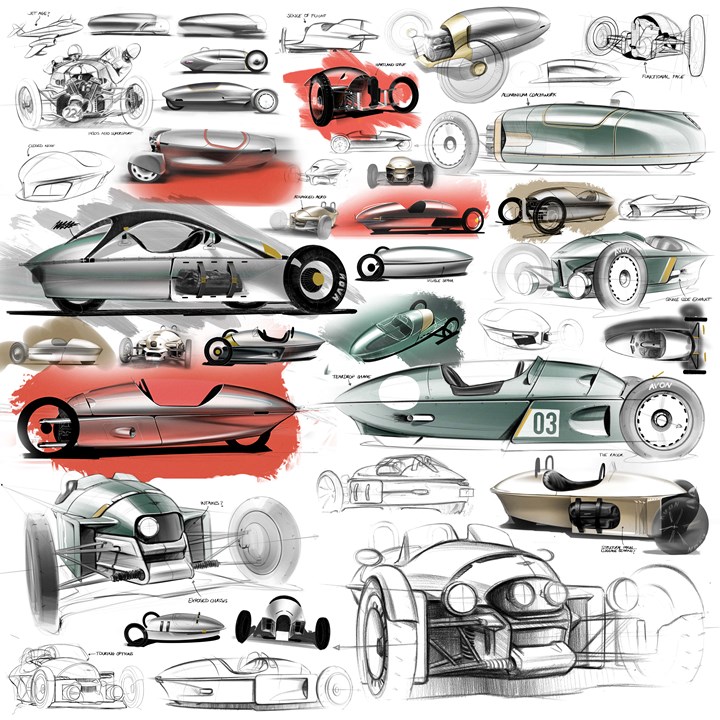

Ideation for the next Morgan three-wheel vehicle. (Image: Morgan)

While there are a variety of three-wheeled motor vehicles that are out there—like those from Arcimoto and Polaris—these tend to come from marques that are comparatively new to the architecture.

New, certainly, in the context of Morgan Motor Company.

This British builder has been producing three-wheelers since 1909, when the founder of the company, HFS Morgan, built a three-wheeler to transport him around the Malvern Hills (approximately 50 miles southwest of Birmingham), where the company is still based.

The company started building the vehicle and variants. It wasn’t until almost 30 years later that it decided to put out vehicles with four wheels.

You would think that given what is the dominant design Morgan would have given up on three-wheelers.

But in 2011 it launched a new version.

In fact, of that vehicle, Steve Morris, Chairman and CEO of Morgan Motor Company, said: “Morgan was founded on the production of three-wheeled cars, and when the 3 Wheeler was re-introduced in 2011 it became a firm pillar of the company’s product range.”

So there will be a new version introduced next year.

The Morgan approach is worth considering, so here’s a long(ish) quote from Jonathan Wells, the company’s Head of Design:

“Morgan cars are often described as ‘analogue’, despite exhibiting industry standard technologies. We believe that in a world of technology, making art of a car’s mechanical elements serves as an antidote to typical vehicle design. Throughout design studies it became quickly apparent that the vehicle must celebrate the model’s mechanical honesty. The sketches demonstrate how these will form a focal point of the new vehicle. The ground-up design is simultaneously a reflection of Morgan’s rich past, relevant to the present, and provides a firm vision of Morgan’s design future.”

- Analogue. Note how he provides a contrast to the Apple-influenced design that OEMs are tripping over themselves to best. Wells noted that they are up-to-date—but in a way that acknowledges what the vehicle is. . .

- Mechanical. Yes, as in “machine.” While they’re not going all Steampunk, there is something to be said for celebrating the mechanism.

Incidentally: Morgan is certainly a boutique builder, producing some 850 vehicles per annum.

///

A Competitor to Consider

The car is by Foxconn. The design Pininfarina. (Image: Pininfarina)

Speaking of design. . . .

While Morgan has been around for more than 100 years, Hon Hai is just 47—and better known as “Foxconn,” which is well known for its work with the aforementioned Apple.

Italian design and coach-building firm Pininfarnia (just to keep up this time theme: founded in 1930) has designed and built an electric luxury sedan for Foxconn, the Model E.

The concept vehicle features an interior that allows the rear seat space to be transformed into a mobile office. It allows “personal mobile devices” to seamlessly connect to the car. (Which just goes to show that Pininfarina is paying attention to its client.)

The vehicle is said to have a power output of approximately 750 hp, a 0 to 62 time of 2.8 seconds and a range of 466 miles.

Beyond the Conceptual

Although this is a concept introduced last week at the International MotorXpo Hong Kong and consequently thought to be, well, a concept and not something to consider in a competitive context (“C’mon, Foxconn builds phones, not cars”), it is worth keeping in mind that a few weeks ago Foxconn and Lordstown Motors Corp. announced that the former is buying the 6.2-million square-foot Lordstown factory in Ohio (excluding the hub motor assembly line, and battery module and pack lines).

What’s more, Foxconn is going to produce the Lordstown Endurance electric pickup under a contract manufacturing agreement in the plant.

And Lordstown and Foxconn are looking into a joint-venture agreement wherein they’ll develop commercial vehicles.

Oh, and Foxconn is also going to be producing vehicles for Fisker in Lordstown.

(Somebody say “economies of scale”)

Maybe there’s more to the Model E than just a concept.

///

The Future’s Uncertain But. . .

Fisker is taking an “asset-light” approach to manufacturing, but outsourcing. That is the forthcoming Fisker Ocean. (Image: Fisker)

And while on the subject of manufacturing. . .

The KPMG 2021 Global Automotive Executive Survey—1,118 execs from OEMs, suppliers, financial services, dealerships, etc. from around the world—has plenty of eye-opening (or tear-causing) items of interest.

When asked what companies are likely to enter the market with branded vehicles, here’s what the respondents say is likely:

- 62% Google

- 60% Apple

- 58% Amazon

- 56% Huawei

- 48% Samsung

- 34% Tencent

- 29% ByteDance

That’s right: Foxconn may be getting into the game, but these companies may follow.

Start ups should not be taken lightly because looking ahead, 31% of the respondents think that within the next 10 years startups will have

Major impact—one or more will take significant market share, causing a reordering of the industry

And while that may seem too extreme (“take significant market share”), know that 61% responded that the new entrants will have

Moderate impact – A few will find some success, but will be eventually bought out by established automakers or will remain niche players

Two points about that:

Developing new tech like that necessary for electric and automated vehicles is expensive. So companies are going to have to look at sources of funding. This could be why when asked “How likely are you to divest nonstrategic parts of your businesses in the next several years?

- 11% Extremely likely

- 34% Very likely

- 30% Moderately likely

So if a company determines that, say, internal combustion is less strategic, what happens to those assets (and suppliers)?

Second

New manufacturers, in some cases, take a different approach, relying on contract manufacturing. It is also called “asset light.” Fisker, for example, is taking this approach.

When asked about whether that approach would allow the new OEMs to be successful, 82% of the global automotive executives said yes.

So even if these new OEMs remain niche, they may be able to be profitable due to their manufacturing strategy.

///

Deep Reality for Driving

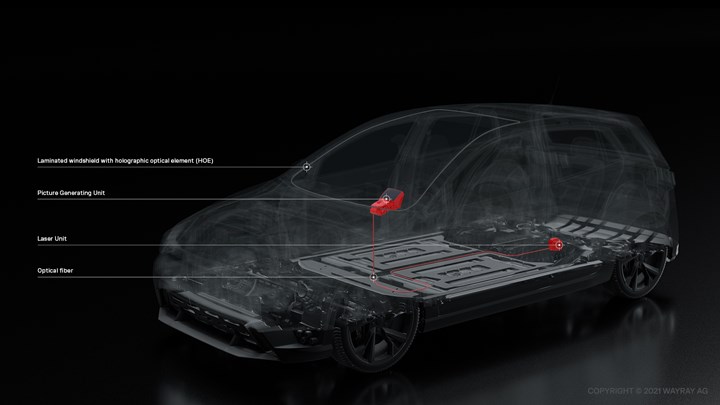

Elements of the WayRay system for holographic display on the windshield. (Image: WayRay)

“I was inspired by science fiction. The idea of an augmented reality, with virtual objects floating in space, has always excited me. I wanted to develop a standard to be able to display 3D content in space.”

So says Vitaly Ponomarev, who went on to found and now head WayRay, a Zurich-based tech firm.

The company has developed what it calls the “Deep Reality Display,” a head-up display (HUD) that doesn’t have a fixed distance for the information that is displayed as conventional HUDs do.

There are four elements to the system.

- A compact laser that generates a red-green-blue beam. The beam is transmitted through an optical fiber to. . .

- The picture generating unit (PGU). Again, this is a compact device that requires about 2.5 liters of volume in the dashboard—compared to about 20 liters for conventional HUDs. Although it is small, the area of the projected field is large: an area of 25° by 8°, or about four times that of an HUD.

- A “holographic windshield.” This is a laminate. It consists of outer and inner glass, then an adhesive layer for each. Between them are a “special function” layer, a holographic optical element, and another “special function” layer. While WayRay describes the function layers as “secretive,” which might seem a bit iffy, the company points out that it worked with Covestro AG and AGP eGlass for the development of the windshield. Not iffy.

- A proprietary augmented reality rendering engine (ARRE). This takes information from sensors, cameras and maps to locate the vehicle and to create the information and images in the right location.

Not science fiction. Entering automotive fact.

RELATED CONTENT

-

On Charging, Sustainable Tires, the Lincoln Nautilus and more

Charging at home, driving on plastic, cameras for exterior, Fisker and Foxconn, and the Lincoln Nautilus reviewed

-

On The Toyota Corolla Cross, Hyundai Santa Cruz, and VW Subscriptions

How to charge an autonomous vehicle. Toyota adds a new crossover. VW gets into the subscription business. Hyundai goes Santa Cruz. And more.

-

On Advanced Design, Brain Function, and Quantum Computing

All about a solar sedan, a new GM design campus, Volvo’s impressive XC90, Porsche first-half sales, Nissan’s brain studies (!), Lucid Care for Lucid Air, and VW’s quantum computing

.jpg;width=70;height=70;mode=crop)