On Automotive: The Green Issue

One of the things that is happening—especially in the European automotive market, for passenger and commercial vehicles alike—is a transition to greener energy. Found herein are several examples of that and other recent developments in automobility.

This week On Automotive

- Quick Charger Quiz

- Green Truck Stop

- Green Gas

- Porsche Mandates Green Energy

- Volta’s Fast Product Development

- Enhancing E-Commerce

- Sense, Don’t Blur

- Tacoma’s Remarkable Run

///

Quick Charger Quiz

Electric charging at a BP station. (Image: BP)

As you know, there is a demand for recharging infrastructure as the world turns more toward electric vehicles (EVs).

There are approximately 42,490 charging stations in the U.S. (Only some 5,000 are fast chargers.)

While the Biden Administration is promoting the addition of more—according to the White House: “President Biden’s American Jobs Plan includes a transformational $15 billion investment to fund this vision and build a national network of 500,000 charging stations”—it is probably 500,000 chargers (analogous to hoses at a gas pump) not stations per se.

Anyway. . .

- Keep that 42,490 number in mind.

The European Automobile Manufacturers’ Association (ACEA) has come out with figures for the number of charging points in the European Union.

Here’s the quiz:

Which country has the most chargers in the EU and what are the approximate numbers in each?

- Netherlands

- France

- Germany

- Italy

- Sweden

The answers are at the bottom of this, so read on.

///

Green Truck Stop

This is what the refueling station at the Port of Gothenburg will look like. Green alternatives in place of diesel generally found at truck stops. (Image: Circle K)

While on the subject of alternative refueling, a group of companies in Sweden have gotten together—the Volvo Group, Scania, Stena Line AB—with the Gothenburg Port Authority in Sweden. The objective is to reduce the amount of carbon emissions from transport to and from the port by 70% through to 2030.

So they’re creating a facility that will include electric charging points, hydrogen gas pumps and bio-based liquefied fuels for heavy trucks that operate at the port. The facility will be operated by fuel company Circle K.

Although there are approximately one million truck movements at the port each year, this is clearly an early-stage undertaking.

That is, by 2024 they will have:

- 10 charging points (maximum power capacity: 350 kW-1 MW)

- 1 hydrogen gas pump for trucks (this represents the ability to fuel 15 trucks every 24 hours).

They’re going to be needing more. Many more. (Just like the number of chargers in the U.S.)

///

Green Gas

If you look carefully you can see a couple of workers on site, which gives you the scale of this large PEM hydrogen electrolyzer. (Image: Shell)

One more European hydrogen piece.

(Why so much interest in what’s going on in Europe vis-à-vis alternative fuels? Based on the numbers of EV charging stations from the first item, it is relatively clear that the Europeans are ahead of the U.S. when it comes to making the transition from gasoline, so it is worthwhile to pay attention to how things are developing in the EU because there are likely to be similar changes in the U.S. going forward.)

Last week the largest facility in Europe to make hydrogen with renewable electricity—1,300 tonnes of hydrogen per year—was opened at the Shell Energy and Chemicals Park near Cologne, Germany.

The PEM hydrogen electrolyzer is the first industrial-scale operation of its kind.

Backing & Objectives

The project is backed by the Refhyne European consortium with European Commission funding through the Fuel Cells and Hydrogen Joint Undertaking.

(Which goes to the point that private-public partnerships are going to be part of the infrastructure transition that will be necessary to get more green vehicles on the road.)

Shell’s Downstream Director, Huibert Vigeveno: “Shell wants to become a leading supplier of green hydrogen for industrial and transport customers in Germany. We will be involved in the whole process — from power generation, using offshore wind, to hydrogen production and distribution across sectors.”

Plans are rolling out to expand the electrolyzer capacity to 100 megawatts.

A word about the system:

- “PEM” stands for “polymer electrolyte membrane.”

- There are also alkaline electrolyzers, but the PEM style is more compact.

- PEM electrolyzers can also operate dynamically with varying loads of electricity, which is important when wind and solar are sources of power and they’re not always consistent.

///

Porsche Mandates Green Energy

Suppliers providing Porsche production operations will be expected to use green energy. (Image: Porsche)

Suppliers of components used in the production of Porsche vehicles that want to keep their contracts must switch to green energy.

There are approximately 1,300 suppliers.

Some of them are going to have to take a deep breath.

“Our battery cell suppliers have already had to use green energy since 2020. And now we are taking the next important step: we stipulate that our series suppliers also use only renewable energy to produce our components, to help reduce CO2-emissions even further,” said Uwe-Karsten Städter, Member of the Executive Board for Procurement at Porsche AG.

According to the company, “Suppliers who are unwilling to switch to certified green energy will no longer be considered for contracts with Porsche in the long term.”

The environment is being taken very seriously in Stuttgart. Very seriously.

(Imagine what your company would do if such a mandate was announced by an important customer. Someone—perhaps you—needs to be thinking that this could happen.)

///

Volta’s Fast Product Development

In but a matter of months, Volta Trucks developed this EV commercial truck chassis. (Image: Volta Trucks)

Yes, this is about an electric vehicle.

Yes, it is from a Swedish company.

But this is more about fast product development than the truck as a European electric vehicle:

- Volta Trucks launched the Volta Zero in September 2020 as a demonstrator vehicle

- Last week the company revealed a running Volta Zero prototype chassis based on the proposed production-specific frame and intended drivetrain components for the finished vehicle

- By late 2021 the company plans to have a test fleet of the 16-tonne commercial vehicles for testing by customers and Volta engineers

- Full scale production is targeted for the end of 2022.

From the first point to the last: this is quick.

Essa Al-Saleh, Volta Trucks CEO:

“While traditional vehicle manufacturers take years to undertake market assessments, design processes and vehicle development, at Volta Trucks, we work at speed because we know that the world’s climate emergency cannot wait, and our customers need vehicles now. In six months, we have designed and developed a running prototype chassis and 18 months from now, we will be building series production vehicles for our customers. This is what they need, this is the speed they need us to work at, and this is what we’ll deliver.”

How can it be so quick?

First know that this is a truck with a specific purpose: intercity logistics.

It isn’t intended to do everything.

It has a range of from 90 to 125 miles, based on whether a 150 kWh or 225 kWh battery is selected.

It has a top speed of 56 mph.

The batteries are being sourced from Proterra.

It is using an e-axle--which integrates the rear axle, electric motor and transmission—from Meritor.

Focus on what you need to do and what you know how to do, and you can go faster.

///

Enhancing E-Commerce

The Rinspeed CitySnap. A better way to deliver containers in urban areas. (Image: Rinspeed)

At first glance that picture might appear to be a food truck.

It isn’t.

Rather, it is the “CitySnap,” a proof-of-concept vehicle Rinspeed AG, the Swiss builder of highly imaginative concept transportation devices.

Some may recall vehicles like the Rinspeed Oasis of 2017, an electric, autonomous commuter vehicle which included a small garden on top of the instrument panel, and do an eye roll when seeing the name “Rinspeed,” but the CitySnap makes some serious sense.

In this case, Frank M. Rinderknecht, Rinspeed chief, got analysis from consultancy EY on the requirements of delivery requirements to individuals in urban areas and the impact alternative vehicles can have.

Portable Lockers

CitySnap carries locker stations that are loaded onto and removed from the vehicle with a swap unit that resembles that is used to handle cargo on aircraft.

The lockers and handling device are from an Austrian industrial automation company, KEBA.

The intent is to have a locker delivered to a determined location and to stay there for a set period of time.

This is not an autonomous vehicle. However the driver does just that, with the load/unload aspects being automated.

To facilitate handling of bulkier or not locker-capable goods, Rinspeed worked with OBE Kinematics to develop a handling system that is located in the rear of the vehicle.

Based on analysis of the delivery requirements in the top 50 cities in Germany, the CitySnap has the potential to reduce the number of delivery vehicles by up to 50%.

Anyone who drives in a downtown business district could certainly appreciate that.

///

Sense, Don’t Blur

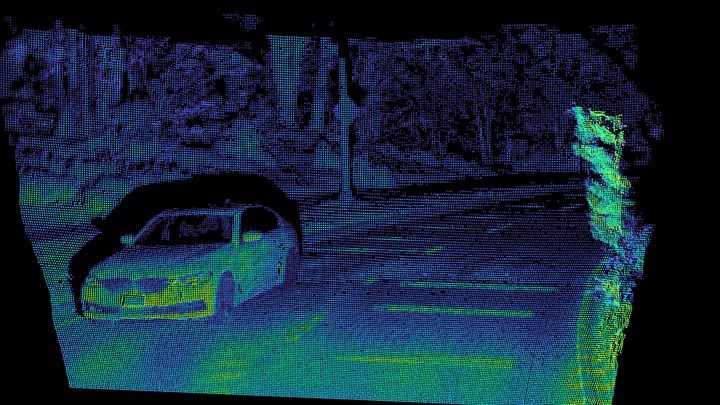

A dense point cloud packed with important information for autonomous driving. (Image: Sense)

“From a safety standpoint, motion blur and reaction time are critical issues when a vehicle is traveling at highway speeds. An autonomous system requires precise depth data in real-time to be aware of the vehicle’s surroundings, particularly in dynamic environments. Data gaps found in legacy scanning systems increase the likelihood to miss small objects, parking lot gates, or even road debris. Only a true solid-state flash LiDAR can provide uniform high-resolution information across the entire field-of-view without motion blur or data gaps—which is exactly what we’ve developed.”

That’s Sense Photonics co-founder and chief innovation officer, Scott Burroughs, talking about the LiDAR platform the company has announced.

The company claims more than 10 million points per second, the greatest number of any automotive system on the market.

And Let’s Not Forget. . .

“As we set out to design this platform, our team realized that mass adoption of LiDAR will only be realized at price points considerably less than today’s LiDAR systems. We built a scalable platform using our 100 percent solid-state SPAD* and VCSEL** components, similar to the LiDAR found in the latest Apple iPhone. These proven components deliver not just scalability and cost-efficiency, but the durability and reliability needed for automotive production.”

That’s Shauna McIntyre, Sense CEO.

Yes, there’s always the cost consideration.

==

*SPAD: Single-Photon Avalanche Diode

**VCSEL: Vertical Cavity Surface Emitting Laser

///

Tacoma’s Remarkable Run

Tacoma has been on an upward trajectory for more than a decade and even though its sales were down in 2020 due to COVID, the number was stil higher than the best year of any of its competitors. (Image: Toyota)

The current generation Toyota Tacoma was launched as a 2016 model year vehicle late in 2015.

So the first full year of sales for this version of the midsize pickup would be 2016.

It is interesting to note how the truck has done in the market during the years since vis-à-vis its competitors.

To wit:

Toyota Tacoma

- 2016: 191,631

- 2017: 198,125

- 2018: 245,659

- 2019: 248,801

- 2020: 238,806

Chevy Colorado

- 2016: 108,725

- 2017: 112,996

- 2018: 134,842

- 2019: 122,304

- 2020: 96,238

Nissan Frontier

- 2016: 86,926

- 2017: 74,360

- 2018: 79,646

- 2019: 72,369

- 2020: 36,843

GMC Canyon

- 2016: 37,449

- 2017: 32,106

- 2018: 33,492

- 2019: 32,825

- 2020: 25,190

Ford Ranger

- 2019: 89,571

- 2020: 101,486

That is a lot of numbers.

But you can see that over that five-year period, no other truck’s best year is better than Tacoma’s least year. You can add the Colorado and Canyon sales for any given year and you still won’t hit the Tacoma’s mark.

The point is simple: The Tacoma is a damn good truck.

Recently I was in a TRD Off-Road 4x4 Double Cab with a 278-hp, 265 lb-ft, 3.5-liter V6. The “TRD” part is for “Toyota Racing Development,” which has plenty of experience banging around in things like desert racing. I will admit to not taking advantage of the TRD-tuned off-road suspension (which includes 2.5-inch FOX internal bypass coil-overs and rear remote reservoir shocks). One interesting aspect is that unloaded—it has a 1,155-pound payload capacity and can tow 6,400 pounds—the ride was level, without the back bouncing as can be the case in some pickups without a load—and let’s face it, unless you are a contractor, odds are you’re driving most of the time without something back there.

Not only does the truck look tough—especially in the Army Green color that is underscored by the black grille and skid plate in the front—but it is tough, as witnessed by those who have purchased the vehicle over the years.

While noted above are the five years it was the number-one choice, know that it has been the best-selling truck in its class for 16 years running.

Tacoma can take it.

///

Charger Answers

The list of countries is in order of the number of chargers installed:

Netherlands—66,665

France—45,751

Germany—44,538

Italy –13,073

Sweden—10,370

According to the ACEA, 70% of the chargers are in the top three countries.

RELATED CONTENT

-

How to Build a Military Vehicle from a Pickup Truck

A real piece of military gear. A real pickup that you can get at a Chevy dealership. A really remarkable story.

-

Frito-Lay, Transportation and the Environment

Addressing greenhouse gas reduction in the snack food supply chain

-

On Military Trucks, Euro Car Sales, Mazda Drops and More

Did you know Mack is making military dump trucks from commercial vehicles or that Ford tied with Daimler in Euro vehicle sales or the Mazda6 is soon to be a thing of the past or Alexa can be more readily integrated or about Honda’s new EV strategy? All that and more are found here.

.jpg;width=70;height=70;mode=crop)