on CAKE and carbon, health and safety in interiors, colorful Porsche, and much more

Life-cycle analysis for carbon reduction. . .sensors inside for health and safety. . .Colorful Porsche 963. . .fire truck for EV battery fires. . .GM EV portfolio in China. . .Toyota Gazoo Racing Supra. . .handling additive powders. . .EVs and ICE suppliers. . .

CAKE and Colleagues Take on Carbon

Can you make a motorcycle—a dirt bike like the Kalk—while minimizing the carbon footprint substantially? Builder CAKE and its colleagues are working hard to do just that. (Image: CAKE)

“The popular term ‘fossil free vehicles’ means greenwash until the entire production has been decarbonized, regardless of the fuel they are running on. In fact, most companies do not know the carbon footprint of their own products.”

That’s Stefan Ytterborn, founder and CEO of CAKE. CAKE is a Swedish company that makes vehicles. Premium lightweight electric motorcycles and mopeds.

“To understand and tackle our own impact, we have measured the emissions from our entire production chain for one CAKE Kalk OR, and started to decarbonize every step to a minimum by 2025.”

CAKE and Vattenfall, a European energy company, initiated a project in 2021: “Cleanest Dirt Bike Ever.”

Recently, suspension supplier products Öhlins Racing joined the CDBE program.

Last week bearing supplier SKF signed on, too.

David Johansson, President Automotive, at SKF:

“We are proud to join like-minded industry colleagues who share the determination that change is urgently needed for a sustainable future. Leveraging our combined expertise, we can trigger and accelerate the creation of products that contributes to this industry transformation.”

When the CDBE project was launched Ytterborn said, “our second most important contribution to the planet is to inspire other manufacturers to step up and do the same.”

Some are.

(If your company want to join, as they’re looking for collaborators on a number of parts, contact cdbe@ridecake.com )

Rather than planting a grove of trees and feeling really good about themselves, they performed an extensive life cycle analysis (LCA) of the CAKE Kalk OR electric motorcycle.

It was calculated that to produce one Kalk OR there were 1,186 kg of CO2 equivalent (CO2e) released into the atmosphere.

(The engineers also determined that the emissions to manufacture a midsize electric car is 25,000 kg CO2e.)

This is a granular analysis.

It was calculated that the bike’s motor is responsible for 9% of the total carbon footprint (107 kg CO2e). And of that:

- 29% is from manufacturing

- 25% from the permanent magnet

- 24% from aluminum

- 12% steel

- 7% copper

- 3% others

They tore down the bike and looked at each element with this level of analysis.

Ytterborn on last week’s announcement:

“One-and-a-half years down the road, we have inspired industry giants to come along with us and push their limits when it comes to decarbonization of production, making an impact lasting beyond the dirt bike. This is what the project is about – creating a fossil free mindset in every part of the production phase – and that is why we are happy to announce that SKF, one of the world’s largest and most advanced bearing manufacturers, is now joining in.”

“Decarbonization of production.”

“Every part of the production phase.”

Some companies would be both happy and satisfied to have a lineup of electric vehicles as CAKE does.

Clearly the people at CAKE realize that going EV is not enough:

It’s how you get there that matters.

///

MEAA Uses a Suite of Sensors for Improved Interior Experiences

This cabin is full of various types of sensors to help assure the health and safety of the driver and passengers. (Image: Mitsubishi Electric Automotive America)

When you think of things like automotive cameras, radars and other sensors, odds are something like [somewhat] autonomous driving comes to mind.

And while Filament Labs, an innovation group within Mitsubishi Electric Automotive America (MEAA), uses exterior sensors for the system it has developed called “Project Jabiru”—for example, cameras are used along with a machine learning algorithm to detect various road hazards (e.g., potholes, traffic cones) and to alert the driver via the vehicle’s infotainment screen; there is also a function in the system that scans the conditions of the road surface which can be used to adjust driving parameters (e.g., if there are icy conditions and the adaptive cruise control is running, the vehicle may be slowed)—what’s really notable about Project Jabiru is its functionality within the vehicle.

Grygorii Maistrenko, Product Owner at MEAA, who works within Filament Labs on Project Jabiru, rattles off the various sensors that are in the cabin, including two cameras, two radars, four thermal cameras, and two directional microphones.

All of these devices are related to monitoring the health, safety and comfort of the driver and other occupants of the vehicle.

For example, consider the thermal cameras. These can be used to measure the body temperature of those in the cabin and adjust the HVAC system accordingly.

But Maistrenko points out there was another function that was very important not all that long ago: remember when you went into a building and had your temperature scanned to determine whether you might have COVID? These cameras can work like those scanners.

An optical camera used for driver monitoring isn’t just to detect things to determine the level of distractedness (not that that’s not important), but it is used with an AI system that permits the determination of the driver’s pulse rate so that should the driver be incapacitated the vehicle can be automatically directed to a safe spot.

Stressed

And on that subject of driver distraction, the system is capable of determining the level of likely emotional stress that the driver may be experiencing and automatically adjusting things like what’s being played on the audio system (something by Mastodon cranked to 11 probably isn’t ideal for someone stressed), the ambient lighting and the HVAC. There is even a “Focus” mode adjustment for the screen: Only the most pertinent information is displayed.

One of the interesting exterior/interior applications that Project Jabiru includes combines navigation and a highly important function for people going places: finding and securing parking.

Mitsubishi Electric worked with navigation company TomTom and parking services provider Parkopedia to locate, navigate to and pay for parking. Michael Horani, director of advanced development, MEAA, acknowledges that activities like this can be performed on a phone, but he points out that functionally it is simpler and more straightforward to do this on a screen that measures 15 inches and is fixed in place rather than something that measures six inches and is held in your hand or attached to a plastic holder.

What’s more—something particularly important in places like underground parking structures, where phone signals are iffy—there is a locator built into the system that allows someone to find their car (at a centimeter level) even when on some subterranean level.

///

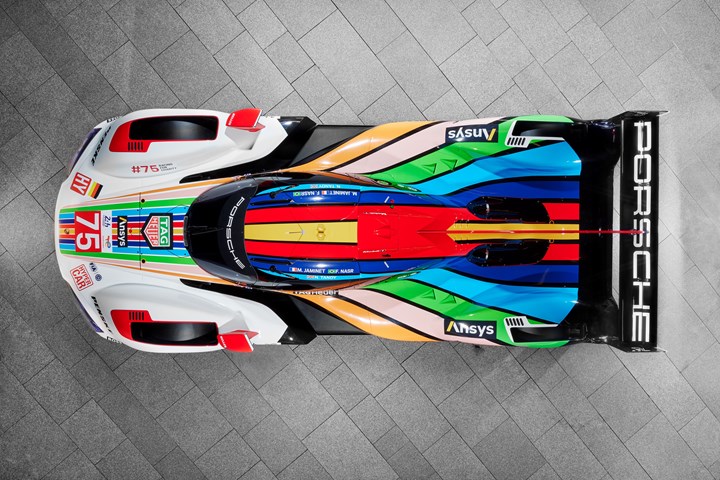

Porsche’s Colorful Historic Tribute

The color scheme of this Porsche 963 that will be fielded by Porsche Penske Motorsport at Le Mans next month is a tribute to 75 years of Porsche sports cars. (Image: Porsche)

As part of its 75th anniversary celebration, Porsche has created three colorful 963s that will compete in the 24 Hours of Le Mans. The three LMDh hybrid prototypes feature 15 stripes in seven colors.

The colors are tributes from Porsches of races gone by.

- Orange stripe: During the 1970s Gulf Oil sponsored Porsche 917s. The orange is a nod to that.

- Pink: In 1971 Porsche designer Anatole Lapine painted a 917/20 race car pink and labeled portions of the vehicle with dashed lines, resembling a diagram of what a butcher would follow to separate a pig. The so-called “Pink Pig” was quite a sensation at Le Mans.

- Green and light blue: Colors used on various models during the 1970s, including one from 1970 that was referred to as the “Hippie.”

- Dark blue: A color used for the Rothman’s paintwork of 1982 and ’83.

- Red: A tribute to the Salzburg-Porsche 917 of 1970, the first Porsche to win the overall race.

- Yellow: Signifying the Porsche RS Spyder that ran in the LMP2 class in the American Le Mans Series from 2006-2008.

The colorful coating is a wrap, not paint.

///

Vehicle Engineered for Putting Out EV Battery Fires in Restricted Places

This fire truck not only can be used where the ceilings are low (as in parking structures) but is equipped with gear to quickly extinguish EV battery fires. (Image: Prospeed Motorsport)

“Fires in electric vehicles powered by high-voltage lithium-ion batteries pose the risk of electric shock to emergency responders from exposure to the high-voltage components of a damaged lithium-ion battery. A further risk is that damaged cells in the battery can experience uncontrolled increases in temperature and pressure (thermal runaway), which can lead to hazards such as battery reignition/fire.”—U.S. National Transportation Safety Board

[Yikes!]

A U.K. company has developed a fire-fighting vehicle specifically targeted at dealing with those thermal runaways, particularly in places like parking structures, which have limited height.

It is the HILOAD, engineered by Prospeed Motorsport and assembled in its facility in York, England.

While it starts with the Toyota Hilux as the donor vehicle, there is a new chassis used to extend the load space. What’s more, the Hilux is a 4x4 and the HILOAD is a 6x6 (a torque splitter system is deployed). The HILOAD can handle a 6,600-pound payload.

To deal with the height restrictions, the truck is 72.8 inches high. (According to J.D. Power—which seems to be an unusual place to find this information, but it has it—the lowest height of any of the fire-fighting vehicles it assessed is 9 feet.)

And as for the battery fires, the HILOAD is equipped with the Coldcut Cobra system.

The system uses high pressure (300 bar) water that carries abrasives.

The fire fighter wields a lance that cuts through the battery case (this is essentially a portable waterjet cutting system) and the water cools the inside of the battery.

The system was apparently tested by the Swedish Civil Contingencies Agency, which found it could handle a battery fire within 10 minutes with just 240 liters (63 gallons) of water, a fraction of the thousands of gallons that may otherwise be needed to extinguish the EV fire.

///

GM Electric in China

While you may think that this Wuling Hong Guang Mini looks like something out of the “Super Mario Bros.” movie, GM sold a lot of these EVs in China last year. (No, not all of them are so, well, flamboyant.) (Image: General Motors)

The Cadillac LYRIQ is, not surprisingly, on sale in the China market. After all, EVs are exceedingly popular in China. As are Cadillacs.

Last year GM sold 194,100 Cadillacs (of all powertrains) in China.

Last year GM sold 134,726 Cadillacs (ditto) in the U.S.

But what else is electric and on sale in China is fascinating.

In the just-released “GM 2022 Sustainability Report” the company lists its EV models in China.

In addition to the LYRIQ there are:

- Chevrolet Menlo

- Buick VELITE 6

- Baojun KiWI

- Baojun Yep

- Wuling Bin Guo

- Buick Electra ES

- Wuling Hong Guang MINIEV family (including variants of the Macaron, Gameboy and Cabrio)

As for the last on that list: there were more than 400,000 of those diminutive EVs sold in China in 2022.

GM’s total EV sales in the U.S. in 2022: 39,096. Or about 10% of that model line alone.

///

Some Surprising Toyota Numbers

GR Supra GT4: you may be surprised at how many have been built. (Image: Toyota)

Toyota’s fiscal year is March-to-March so it wasn’t until last week that it was able to announce its FY 2022 global production: 9.13 million vehicles.

Better than the previous year—8.57 million—but still off from its original 2022 target (which was reduced twice during the year): ~9.7 million.

(Yes, missing chips. Still.)

Among the 9.13 million were the GR Supra GT4, a car, based on the production Supra, but transformed by Toyota Gazoo Racing (thus the “GR” in the name) for customer racing.

But not many customers.

Last week Toyota Gazoo Racing announced that it produced its 100th GR Supra GT4.

That’s the total number since the car went on sale in March 2020.

To mark the accomplishment they are producing a special commemorative GR Supra GT4 100 Edition.

Production run?

Three.

///

Winning Tech for Additive

HP has developed a powder handling system to increase the efficiency of additive manufacturing. (Image: HP)

One of the things about additive manufacturing is that compared with more traditional processes (e.g., machining, molding, stamping) it tends to be slow.*

So it is not the sort of thing that an operator is likely to be on hand for.

The people at HP, who provide printers for polymers and metals, have come up with something that is highly useful for those who are interested in actual production processes for additive parts: the HP Jet Fusion 3D Powder Handling Automation Solution.

This is a closed-loop, pneumatic system that provides, according to Francois Minec, global head of 3D Polymers at HP, the ability to simplify workflow while ensuring the quality of the materials that are being provided to the printers as well as traceability. In addition to which, the system can handle the requirements of up to 15 printers.

While handling materials isn’t as fascinating as watching a build, those who are actually doing the builds (unlike those of us who see a machine on occasion, in a facility or at a trade show) don’t spend a whole lot of time watching (they are builders, not tourists).

What’s more, in order to make the move from prototyping to production, automated systems for providing the powers are essential.

Think of material handling as the blocking and tackling of additive manufacturing.

And as Vince Lombardi once said of those actions in his realm:

“Football is two things. It's blocking and tackling. I don't care about formations or new offenses or tricks on defense. You block and tackle better than the team you're playing, you win.”

Arguably the same holds in producing things, too. Make sure you’re getting the materials where they need to be, when they need to be, and in the condition they need to be, and you’re likely ahead of the game.

==

*Yes, if the entire process is taken into account—to say nothing of cost savings for things like tooling—it can be comparatively timely. But still, watch parts being built with additive, and before long you’ll be looking at your watch.

///

You’ve Been Warned

Suppliers of components used in internal combustion engines should heed a warning from Michael Robinet, Executive Director, Consulting Services, S&P Global Mobility:

If (a) they act as if the transition to electric vehicles is something of a fad or (b) organizationally they are not making their operations relevant, then, Robinet writes in a special report: “there will be a brutal shakeout and consolidation among engine, transmission, and driveline suppliers in addition to those in the fuel and exhaust systems sectors. The victims will be those who failed to plan ahead and listen to their customers.”

So for those suppliers, there are four choices, according to Robinet:

- Divest from ICE, and shift to BEV components

- Milk the cash cow dry, while shrinking to an eventual shutdown

- Double down to become the dominant part supplier

- Position to be acquired

The EV transition isn’t going to happen overnight. But not paying attention to what is going on is going to end ugly.

]]]

RELATED CONTENT

-

On The Jeep Grand Cherokee, 2022 Nissan Pathfinder, and More

An inside look at the Detroit Assembly Complex-Mack; a innovative approach to waste-free, two-tone painting; why a forging press is like an F1 car; and other automotive developments.

-

FCA Opens the Door to The Future

FCA introduced a high-tech concept vehicle today, the Chrysler Portal, at the event previously known as the “Consumer Electronics Show,” now simply CES.

-

Study: How States Should Update Traffic Laws for Autonomous Cars

U.S. states should require that all automated cars have a licensed driver on board, suggests a study by the Governors Highway Safety Assn.

.jpg;width=70;height=70;mode=crop)