On Ford Maverick, Toyota Tundra Hybrid, and GM's Factory Footprint

GM is transforming its approach to the auto market—and its factories. Ford builds a small truck for the urban market. Toyota builds a full-size pickup and uses a hybrid instead of a diesel. And Faurecia thinks that hydrogen is where the industry is going.

#hybrid

Why GM’s Factory Footprint Matters

Inside Factory ZERO. Transforming an existing facility to produce EVs is faster than starting from scratch, GM’s Johnson notes. (Image: Jeffrey Sauger for General Motors)

General Motors held a two-day program for the investor community last week. The objective was to convince Wall Street, in effect, that GM is a to-the-moment-future-oriented firm, not some sort of old-school tin-bender.

As its description put it:

From Automaker to Platform Innovator

And the “platform” just isn’t the vehicular architecture that many of us are familiar with. It is the “digital platform” that is essential to this. The executives making presentations laid out the company’s plans that will contribute to it doubling its annual revenue to $280-billion by 2030 while increasing its operational profit margins from 7.9% in 2020 to from 12 to 14%.

Chief Financial Officer Paul Jacobson put it simply: “This is real.”

- While much of the discussion was about rolling out electric vehicles based on the Ultium physical platform and over-the-air updates and subscription services with the Ultifi digital platform, while there was some shade thrown at competitors (e.g., GM President Mark Reuss said of the Silverado electric vehicle that they’ll debut at CES in January, “We didn’t take our ICE architecture and turn it into an EV like our competitors,” boasting, “No one will be able to touch us in the EV truck space,” adding, “Most start-ups have no customer base at all.”). . .

- While there were projections of “tens of thousands, hundreds of thousands” Cruise Origin autonomous vehicles on the road that could contribute $50-billion annual to GM, according to Dan Ammann, CEO of Cruise. . .

- While there was that and more, it was interesting to listen to Gerald Johnson, GM executive vice president, Global Manufacturing and Sustainability.

Some might imagine that the existing manufacturing footprint that GM has is something of a liability, Johnson says it is an advantage. In terms of speed and economic efficiency.

Case in point: Factory ZERO.

Previously the GM Detroit-Hamtramck Assembly Center, the factory produced products from the Cadillac Deville to the Chevy Malibu.

Johnson noted they’ve gone from announcement (January 2020) to pre-production (GMC HUMMER EV) in 20 months. (Incidentally: The Cruise Origin will also be built there.)

Johnson said that by transforming existing factories and leveraging existing assets (remember: EVs and ICE-based vehicles have lots of components in common, from sheet metal to seats) they can not only accelerate operations (he suggested that getting a greenfield up and running can take as many as four years), but save from $1- to 1.5-billion on CapEx.

Know this

Given that the company plans to have as much as 50% of its auto sales revenues being based on EVs by 2030, look for more factory transformations at GM.

And this, too

CFO Jacobson said that it is key to get vehicle on the road because “that’s where the revenue streams begin. The model is very different from the way it was before.”

That is, before the OEM sold the vehicle and that was that. Now the plan is to sell the vehicle and to keep selling things—not merely aftermarket accessories, but digital services.

This isn’t exactly the razor-razor blade model, but a “very different” approach to the auto industry.

///

Maverick: Simply

2022 Ford Maverick: Looks like a truck. Works like a truck. Is a truck. (Image: Ford)

A definitive descriptor.

“This is a truck. It was designed as a truck.” Chris Mazur, Maverick chief engineer, couldn’t be much more straightforward about the proposition.

Although it has a unibody structure—not a body-on-frame, like its siblings the Ranger and the F-150--its C2 platform, also used for the Escape and the Bronco Sport*, has been structurally supplemented in order to make this a vehicle that is capable of handling a standard payload of 1,500 lb. and of towing 2,000 lb.

That’s with the standard powertrain. (More on that in a moment.)

With the optional 2.0-liter EcoBoost and an optional tow package, the Maverick can tow up to 4,000 lb.

The powertrains.

This is what could be the most interesting aspect of the Maverick: The standard powertrain is a hybrid. It is based on a 2.5-liter Atkinson-cycle engine combined with a Ford-built electric traction motor that is integrated with a continuously variable transmission. The system output is 191 hp and 155 lb-ft of torque. This setup provides an EPA-estimated city fuel economy of 40 mpg—and that number is the important one because the Maverick is positioned as being an urban vehicle. (More on that in a moment.)

The optional, 2.0-liter four-cylinder engine (the 2.5 is also a four) produces 250-hp and 277 lb-ft of torque. It is mated to an eight-speed automatic.

Mavericks with the 2.0-liter are either front-wheel drive or all-wheel drive (optional); the hybrids are FWD.

In the city.

The target audience for the Maverick is someone who probably lives in an urban environment rather than in a suburb or out in the country. Because space is at a premium in the city, and a larger truck would be harder to accommodate in that environment.

Consider:

- The Maverick is 199.7 inches long, 68.7 inches high, and 72.4 inches wide.

- The Ford Ranger is 210.8 inches long, 71.1 inches high, and 85.8 inches wide

- And the F-150 is 231.7 inches long, 75.6 inches high, and 95.7 inches wide (with standard mirrors).

Which do you think is going to be more maneuverable in city traffic?

(The Maverick has a 40-foot, curb-to-curb turning radius.)

The Maverick has a 4.5-foot bed on the back of the five-passenger cab.

About the bed.

They’ve actually trademarked the name of the bed: FLEXBED.

While every contemporary truck out there has features inside the box that are meant to facilitate carrying things, the Maverick bed, in some ways, goes further.

First know that dimensionally it is capable of handling 4x8 sheets of plywood over the wheelhouses. And that the lift-in height, at 30 inches or less, makes getting things in manageable. (The height of the box side is such that it is fairly easy for adults to reach over and access the inside.)

There are slots stamped into the bed, one to accommodate a 2x4 and the other a 2x6 so that users are able to load and secure bikes or kayaks.

Makers.

Which leads to a keen characteristic: While there are more sophisticated things like bike racks that are readily available, the Maverick is designed and engineered for the DIY and maker crowd.

As for the first: there is an available Ford cargo management system. The box has four threaded bolt holes, two on each side near the top, that allow a DIY cargo management system: simply go to a hardware store and pick up a C-channel, then bolt it in place.

Another hack.

Jay Kistler, a vehicle engineering specialist on the program, notes that they’ve seen some truck owners do some rather dicey/splicey things to wiring in their beds in order to get lighting back there. Yes, you can get factory-installed lighting. But they’ve put built-in 12-volt electrical power that’s accessible on either side of the bed simply by removing a plastic cover. No kludges required.

As for the maker, the interior has a slot on the back of the front console. The location means it is readily accessible to the rear-seat passengers. But this isn’t just a generic slot. It is designed for the “Ford Integrated Tether System,” which has a specific configuration. Ford is making the CAD file for the hook available so that people with 3D printing machines can create their own objects for use with FITS, such as cupholders or cord organizers.

We put it to Kistler: are people really going to print things like small trash buckets for their Mavericks? And he says that according to their research, the answer is yes, not only because they want personalization, but because they like to do stuff.

And doing seems to be at the heart of the Maverick.

*To give you a sense of the flexibility of the platform: the Maverick has a wheelbase of 121.1 inches. It is 106.7 inches for the Escape and 105.1 inches for the Bronco Sport. Same platform and a wheelbase difference as much as 16 inches.

///

Powering the 2022 Toyota Tundra

2022 Toyota Tundra: Yeah, it’s got a hybrid in there. (Image: Toyota)

The engine for the Tundra is a 3.5-liter, aluminum block V6 with twin turbochargers. (The previously available 5.7-liter V8 is no more for the truck.)

There are two variants of the engine. Both are mated to a 10-speed electronically controlled automatic. Both are available in 4x2 and 4x4 layouts.

The standard i-FORCE produces 389 hp @ 5,200 rpm and 479 lb-ft of torque at 2,400 rpm.

(The aforementioned V8 produces 381 hp @5,600 rpm and 401 lb-ft @ 3,600 rpm. Which explains why it has been replaced by the more-efficient V6.)

The MAX

Then there is the i-FORCE MAX. It produces 437 hp @ 5,200 rpm and 583 lb-ft of torque at 2,400 rpm.

What’s the difference between the two engines?

The MAX is a hybrid.

It has a permanent magnet motor that produces 36 kW—or 48 hp—and 184 lb-ft of torque. It is located between the engine in transmission (a.k.a., “P2 position”).

Uh, a Prius powertrain?

This is not, chief engineer Mike Sweers explains, a truck variant of the Prius system. For one thing, the Tundra system is, well, one thing: there is a single motor/generator, not a tractive motor and a motor/generator, as found in a Prius.

What’s more, the Prius hybrid is integrated with a continuously variable transmission, not a step-gear transmission as in the Tundra.

For another thing, whereas the Prius is engineered for fuel efficiency, the Tundra hybrid system is meant to provide power.

What about a diesel?

Sweers explains that he was initially thinking about a diesel for the Tundra.

The ’22 Tundra and the new Land Cruiser 300 Series share a newly developed platform, and the Land Cruiser is available with a 3.3-liter twin-turbo V6 that produces 305 hp and 516 lb-ft. He considered that.

But then he saw the advantage that the hybrid system could provide: when getting on the throttle the hybrid motor can fill in the power until the turbos spool so that there is linear acceleration. Given the 583 lb-ft at a comparatively low 2,400 rpm, there is a lot of capability from the moment the throttle is depressed.

He admits, “I was not a hybrid guy.” And he says that he’d been biased toward the diesel until he personally racked up miles in the hybrid.

“Once I actually experienced it in the truck it was like, ‘Wow! I don’t need a diesel. I’ve got instant torque and the power I need.’”

(A pickup powertrain vignette: Sweers says they were testing the truck on a ranch in Montana. He met with the rancher who had a fleet of pickups. All gas-powered. No diesels. Sweers asked why. The rancher responded, “Did you ever try to start one at -40°?” Use a block heater, Sweers suggested. “I don’t have time for that,” the rancher responded. Two things about Sweers: he’s pragmatic when it comes to engineering a truck and he thinks about productivity. No diesel for the Tundra.)

Didn’t expect this

Here’s something interesting about the hybrid system:

The battery pack is a. . .sealed nickel-metal hydride battery. It consists of 240 cells that are contained in 40 modules. The maximum system voltage is 650 v.

Hasn’t the world gone lithium-ion?

That’s one of the reasons why the Tundra has a Ni-MH battery.

Sweers points out that demand is driving up the cost of Li-ion batteries. What’s more, the demand is making it more difficult to source.

While the Li-ion battery has greater energy density and therefore could provide the same amount of power in a smaller package, here’s something to keep in mind: the Tundra is a full-size pickup truck.

It is big (e.g., a Double Cab with a long bed has a 164.6-inch wheelbase, is 252.5 inches long , 80.2 inches wide, and 78 inches wide).

The Ni-MH battery is housed beneath the rear seat. There’s room. So that’s not a concern as it is with vehicles with a considerably smaller footprint.

In addition, Sweers says that there is recycling capability for Ni-MH batteries. (After all, they’ve been using that battery chemistry in the Prius since it went on sale in 1997, so they know something about that.)

Sweers lives on a farm. He understands things like the importance of recycling for the environment.

///

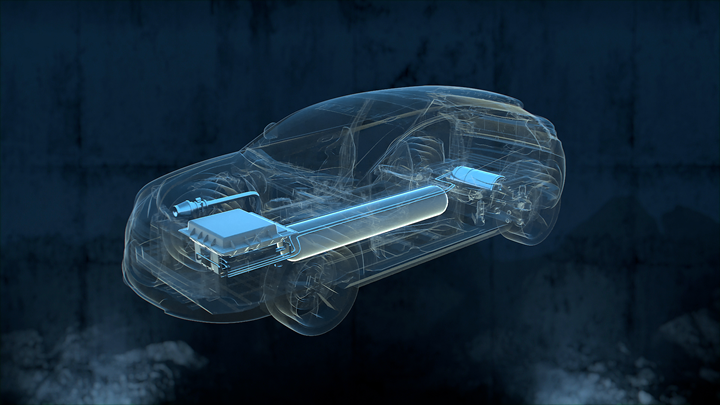

Faurecia & the Hydrogen Future

This is what the future of a powertrain system might look like: Power by hydrogen. (Image: Faurecia)

There are two things that Jose-Vicente March, Vice President Zero Emissions, Faurecia Clean Mobility North America, is certain of:

- Hydrogen is going to do nothing but increase in importance for transportation applications, including light vehicles (company stats show that there will be 2.5-million hydrogen-powered vehicles, of which 500,000 will be commercial vehicles, globally on the road in 2030)

- It is a good business practice to be resourced for a growing market (nowadays tech shifts quickly so companies that aren’t ready. . .)

“It’s not a matter of if. It’s when?” March says.

“Don’t they make seats?”

While most people might be familiar with Faurecia for its seats and interiors or its Clarion Electronics, one of its four business groups is Clean Mobility. It encompasses operations for ultra-low emissions for both passenger cars and commercial vehicles.

And zero emissions.

Which is where hydrogen comes into play.

March says that they’re taking a systems approach to fuel cell electric vehicle (FCEV) components.

As in developing and producing hydrogen storage systems (e.g., tanks, valves and components) fuel cell stacks, and auxiliary elements (electronics, compressors, etc.).

It estimates that its portfolio covers about 75% of a hydrogen powertrain.

The stacks are being created by a joint venture company Faurecia has with Michelin, Symbio. It is developing “StackPacks,” scalable elements to meet vehicle needs.

The company is getting orders.

Not science experiments

March notes that they’re providing storage systems to Hyundai for use in its fleet of Xcient fuel cell heavy-duty trucks in Switzerland—as many as 1,600 trucks by 2025.

It is providing Stellantis with the fuel cell stack and storage system for its light commercial vehicles (e.g., the Opel Vivaro-e Hydrogen) launching this year.

(One can well imagine something like a Ram ProMaster with the system. . . .)

Faurcea has 11 “major” customers for its hydrogen products with booked sales for 2022.

Hydrogen challenges

Earlier this year Stellantis presented its overall approach to hydrogen during which it stated “only four challenges remain.”

- Full-scale, economic production of green hydrogen (H2 produced from electrolysis powered by electricity generated by renewable sources)

- Nation-wide networks of hydrogen filling stations (Stellantis made the presentation in Europe, so “nation-wide” means something different than across the U.S.)

- Integration of the fuel cell system into the vehicle platform

- Cost reduction from economies of scale (which goes back, in part, to #3: the light commercial vehicles that Stellantis is producing handle ICEs as well as batteries and fuel cells)

Not if. When.

RELATED CONTENT

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

-

Special Report: Toyota & Issues Electric

Although Toyota’s focus on hybrid powertrains at the seeming expense of the development of a portfolio of full battery electric vehicles (BEVs) for the market could cause some concern among those of an environmental orientation, in that Toyota doesn’t seem to be sufficiently supportive of the environment, in their estimation. Here’s something that could cause a reconsideration of that point of view.

-

On The Jeep Grand Cherokee, 2022 Nissan Pathfinder, and More

An inside look at the Detroit Assembly Complex-Mack; a innovative approach to waste-free, two-tone painting; why a forging press is like an F1 car; and other automotive developments.

.jpg;width=70;height=70;mode=crop)