on Fuel Cells (mobile & not), EV Charging (use & number) & Other Automotive Initiatives

Bosch fuel cell investment. . .Toyota & stationary fuel cells. . .electric charging challenge. . .vehicle tech deployment. . .’23 Integra review. . .a Bentley in the apartment. . .

Bosch Driving the Hydrogen (Near) Future

Fuel cell production in the Bosch Bamberg plant. It is coming to America. (Image: Bosch)

“The hydrogen economy holds great promise and at Bosch we are all in.”—Mike Mansuetti, president of Bosch in North America

All in as in making an investment of >$200-million for the production of fuel cells for vehicle propulsion in its manufacturing facility in Anderson, South Carolina. Presently there are some 1,200 associates in Anderson producing powertrain sensors, electronic control units and other products for the Bosch Mobility Solutions business sector.

The production is planned to commence in 2026. It will mean “at least” 350 new jobs.

An additional 147,000 square feet of floorspace (including things like clean room facilities) are being constructed.

Conceptually, the operation of a fuel cell is simple:

- Hydrogen ions pass over fuel cell plates and are combined with oxygen with the result being the generation of electricity. The emissions are water.

Constructionally*, building a fuel cell isn’t simple:

- A fuel cell stack consists of some 3,200 parts. There are more than 400 layers in a stack and more than 100 unique components.

Mansuetti:

“In order to successfully bring fuel cell technology to market in mass scale, it requires a combination of extensive experience in research and development, systems integration and complex manufacturing process. Bosch is unique in its ability in all these areas. The work we have already done in commercializing fuel cell technology builds on our extensive experience in developing and manufacturing products for the internal combustion engine at scale.”

No stranger

Bosch is no stranger to producing fuel cells.

This past May Dr. Markus Heyn, member of the Bosch board of management and chairman of the Mobility Solutions business sector, said:

“We will start production of fuel-cell powertrains for trucks this year. Our technology already completed a good 100,000 test kilometers in 2021, driven by Chinese prototypes. Our Bamberg plant in Germany will start producing fuel-cell stacks in 2022. By the middle of the decade, we aim to be producing stacks with a gigawatt output at that site – our giga-factory, if you will. To this end, assembly of the complete fuel-cell system will begin in Stuttgart-Feuerbach in 2023, with some components also being supplied from Homburg. This cooperation clearly shows that our core plants are generating innovations. The Wuxi location, which serves our Chinese customers, will also be involved.”

In addition to those Chinese prototype kilometers, there are miles being racked up in the U.S. with Class 8 fuel cell trucks from Nikola that are using Bosch tech.

Heyn said that they are working toward a 2030 goal: “it should cost no more to operate a fuel-cell truck than a diesel.”

What’s more

Bosch is also building stationary fuel cells that can be used in a variety of applications for local power demands (e.g., in city centers). The company plans to have commercially available stationary fuel cells by 2024.

Scale matters to help drive the affordability of fuel cells.

*Yes, I made up that word.

>>>

Toyota, Fuel Cells and the NREL

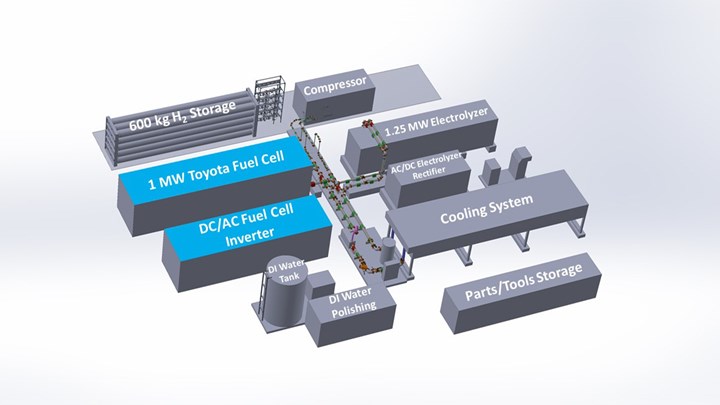

Schematic of the fuel cell system for NREL Toyota is working on. (Image: Toyota)

And speaking of fuel cells. . .

Toyota is nothing if not stalwart in its support of fuel cell technology.

Last year it sold 2,629 fuel-cell powered Mirai sedans. During the first half of this year it moved 1,358 cars, which could mean about the same number for all of 2022. Not a huge number in automotive terms. But significant when you think about the few fuel cell vehicles out there.

Back in 2017 Toyota started working on Project Portal, which involved using Mirai stacks in Kenworth Class 8 trucks, trucks that went to work at the Ports of Long Beach and Los Angeles for drayage (think of it as “first mile” transport of goods). There were 10 Kenworth T680s powered by hydrogen. Even with the short distances involved, with work and test miles combined, it was on the order of 60,000 miles accumulated.

Given that there were four customers—United Parcel Services, Total Transportation Services, Southern Counties Express, and Toyota Logistics Services—that depend on deliveries, presumably this approach works.

And now. . .

Last week, Daniel Leighton, a research engineer at the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), said, “We will study the scaling of PEM [proton exchange membrane] fuel cell systems for stationary power generation to understand what the performance, durability and system integration challenges are.”

The study will be based on a 1-megawatt fuel cell power generation system that will be built at the NREL facility in Arvada, Colorado, a three-year-$6.5-milion collaboration between NREL and Toyota Motor North America.

Yes, fuel cells that are powering vehicles will be combined to develop the NREL system.

(A solid polymer electrolyte fuel cell in a Mirai produces 128 kW.)

About the NREL project Christopher Yang, group vice president, Business Development, Fuel Cell Solutions, Toyota, said: “The application of our modules in deployments of this magnitude shows the scalability of Toyota’s fuel cell technology, whether it is a single fuel cell module for one passenger vehicle or multiple systems combined to power heavy-duty equipment.”

Still on the road

Toyota is continuing to put fuel cells on wheels.

A Toyota a spokesperson told us: “We plan to begin producing FC modules next year for customers looking to convert their trucks/fleets to FC powertrains.”

And on the subject of stationary apps, he stated: “Yes, it’s definitely something we have been exploring.”

>>>

We’re Going to Need a Bigger Charger Deployment

Things like this are valuable. . .but insufficient. (Image: Ford)

- “This study investigates how many charging stations and outlets may be required at various stages of EV market development in different regions to satisfy actual demand and to instill within end users the confidence that availability will be sufficient.”—EV Charger Deployment Optimization: An Analysis of U.S. State-level Electric Vehicle Supply Equipment Demand Forecast and Supporting Infrastructure Considerations

Last summer the Fuels Institute had S&P Global Mobility conduct that study.

Last week the study was released.

Although the announcement by the state of California last week about the adoption of the Advanced Clean Cars II rule last week that will have 100% of new light vehicles sold in the state zero-emission vehicles by 2035 may make some of the report’s findings somewhat off, as will the Inflation Reduction Act’s EV tax credit scheme, directionally it is probably right on.

As in. . .

- “By 2030, California is expected to contribute 17.4% of new plug-in EV registrations with the top 15 states contributing a combined 73.4%.”

And:

- “New EV registrations per year are expected to hit 1.75 million in 2025 and 2.75 million by 2030. By this 2030 timeframe, S&P Global Mobility estimates EVs will make up 5.9% of the U.S. registered vehicles.”

Not enough

The study calculates the ratio of vehicles to chargers predicated on a study released in August 2021 by Mobilyze.ai and the Toyota Mobility Foundation that has it that there should be one public charging station for 10 to 15 EVs “even when the housing mix enables easy access to home charging.”

Yes, home charging is useful and necessary, but there needs to be plenty of public chargers just the same.

The current number of public charging stations is 115,197, the study says.

Clearly, more are needed.

No surprise

On the subject of where the chargers should be: No surprise.

Because California is found to have 40.9% of all EVs and plug-ins (as of July 2021), that is the #1 priority for chargers.

The next bucket is Texas, Florida, New York and New Jersey.

Somewhat surprising

The third priority list consists of Alabama, Arkansas, Kentucky, Louisiana, Mississippi, North Dakota, South Dakota, West Virginia and Wyoming.

While that list may seem rather unusual, the rationalization is that the states, “especially in the South, will provide crucial charging corridor support for highway transportation between states with higher EV VIO [vehicles-in-operation] (such as Florida and Texas). So, building out infrastructure in Priority 3 states will not only benefit the local growth in EV VIO but also for those passing through.”

Positivity

While the study shows that there needs to be coordination, largely at a local level, to coordinate the build-out of chargers (e.g., utility companies, charging network operators, shopping mall proprietors), the Fuels Institute ends on an optimistic note:

“In summary, the trajectory of EV adoption and the installation of the supporting EVSE infrastructure is on a good trajectory in many parts of the U.S.”

Still, there is a considerable delta between 115,197 and 1.5 million.

>>>

Tech Experience & Innovation

Genesis GV60 interior. The company leads in tech experience. (And makes really nice vehicles, too.) (Image: Genesis)

At the risk of becoming the weekly source of information about still another J.D. Power study, a brief note about the 2022 U.S. Tech Experience Index (TXI) Study, which looks at consumers’ responses to advanced vehicle tech (35 types in four categories—convenience, emerging automation, energy and sustainability, and infotainment and connectivity) is worth considering.

Genesis has the highest overall and premium brand Innovation Index score of 643 (on a scale of 1,000). Hyundai is the highest in the mass market brands at 534. What do those two companies have in common? They’re both part of the Hyundai Motor Group. (As is Kia, which came in second in the mass-market category, at 495.)

If the vehicle of the future is going to be tech-intensive, OEMs from the U.S., Europe and Japan really ought to be looking at what the South Korean brands are up to.

Looking very hard.

Innovate or. . .

Know this from Kathleen Rizk, senior director of user experience benchmarking and technology at J.D. Power:

“Innovation is non-negotiable. The fact that the average PP100 for a technology is high should not discourage automakers from innovating, as there is often a wide range of total problems experienced for a technology across the brands.”

>>>

2023 Acura Integra A-Spec Tech

"We are proud the Marysville Auto Plant has been chosen as the exclusive global production home for the 2023 Acura Integra that will play a key role in attracting the next generation of driving enthusiasts to the Acura brand"--Arjun Jayaraman, plant lead at MAP. (Image: Acura)

Several years ago I rolled up to a restaurant valet stand in downtown Detroit. . .in a Honda Fit.

It was (a) winter and (b) there was no discernable place to self-park. So the valet.

When the business dinner was concluded and I walked out of the restaurant, there was the Honda Fit, where I left it. It would have been one thing had I been in a Acura. But the entry-level model (at the time) for Honda?

That’s not the sort of thing that places like that generally have out front.

But seems that the valets who were working that night weren’t familiar with driving a car with a manual transmission.

(I am not making this up. Arguably no one could survive as a valet in, say, LA without the ability to use a clutch, but Detroit, by and large, with the exception of things that drive in the Woodward Dream Cruise, is pretty much automatic transmission terrain.)

The point of this is a remarkable statistic from Acura regarding the 2023 Integra:

When reservations were opened for the sport sedan, 65% opted for the six-speed manual.

That is incredible.

Clearly, there are those who really want to drive an Integra (with “driving” in this case being defined as the level of involvement that a manual demands).

The car

The ’23 is the fifth generation Integra. The first gen was model year 1986. Model year 2006, which was the fourth generation, was the last before the return of the car which has always pretty much had as its mission to provide attainable yet upscale performance.

The current car, for example, is powered by a 200-hp 1.5-liter turbocharged four mated to the aforementioned six-speed manual (there is also a CVT available for the Integra) and the vehicle as-driven has an MSRP of $35,800. There was $500 for the optional paint (“Liquid Carbon”).

There are three trims for the car: “Integra, ” “Technology Package” and “A-Spec.”

So for purposes of pricing know that the base is $30,800; A-Spec adds $2,000 to that; Tech adds another $3,000. The tech package is where the six-speed comes in, so it seems as though the sub-$40K price is a good place for the Integra to be, given that 65% reservation rate. The stuff that comes along for the $35,800 (i.e., base + A-Spec + Tech) includes: adaptive damper system (choose from Sport, Normal and Comfort), 16-speaker 530-Watt ELS STUDIO 3D audio, head-up display, nine-inch color touchscreen, wireless charging, wireless Apple CarPlay and Android Auto, synthetic leather with Microsuede inserts, driver’s seat memory with 12-way power adjustment, four-way power passenger seat, front and rear parking sensors, 18-inch wheels, and LED fog lights.

In terms of styling, the Integra has a strong-yet-understated exterior. Although the design was performed in Japan at the Wako Studio, given that the Acura vice president and brand officer is Jon Ikeda, Art Center grad who got his first job as a designer in the Honda Tokyo studio, the involvement from this side of the Pacific was undoubtedly strong.

On the inside the cabin is clean, uncluttered. . .although of the three interior colors available for the A-Spec—Ebony, Red, Orchid—the vehicle driven had Red, which could be written RED. It is hard not to notice that.

Odds are those who pick that color for the nicely bolstered seats are going to also opt for the manual.

Quotidian

But for all the visual and mechanical sportiness, there is one thing that cannot be overlooked:

- This is a car that is meant to be driven—every day.

And that means the days when you’re not carving corners but simply conducting chores, whether that is taking the kids to school or going to Costco.

So to tick a couple boxes of regular existence:

The Integra is a sedan that offers 95.8 cubic feet of passenger volume; people can ride in the back seat. It is a hatch that offers 24.3 cubic feet of cargo room behind the second row.

Still, I wonder: Does that 65% drive in any other way than a spirited manner?

>>>

Live in Your Car: The Other Half Approach

Why wouldn’t you want a Flying Spur in your living room? (Image: Bentley)

A Bentley Flying Spur is:

- 209.29 inches long

- 58.43 inches high

- 87.40 inches wide (though if you remove the side-view mirrors, it is 77.87 inches wide)

- 5,373 pounds kerb weight

Let’s face it: A Grand Tourer is not diminutive.

Why Is This Interesting?

Bentley is constructing apartments in Miami.

The Bentley Residences.

Offered with these lux living spaces is a three- or four-car garage.

However, this is Bentley so we’re not talking about just some polished concrete in a parking structure.

Residents can park one of their cars in their residences.

How It Works (So You Don’t Have To)

The 749-foot building is being constructed with four “Dezervators,” which were developed by Bentley and contractor Dezer Developments.

You roll up to the building. An RFID code is scanned. Lights direct the driver to the appropriate Dezervator. The unit grips the tires and pulls the car into position on the platform.

Then up goes the car. With you in it. Without having to perform any tedious tasks, like selecting the right floor.

That’s done for you.

Even if you live on the 61st floor.

In case you’re wondering: Apartments start at $4.2-million.

But what is it they say about needing to ask. . .?

>>>

ADAS Terms to Know (4)

Here is a continuation of the series of nomenclature defined by AAA, Consumer Reports, J.D. Power, National Safety Council, PAVE, and SAE International to make things more understandable regarding autonomous tech:

PARKING ASSISTANCE

Backup Camera Displays the area behind the vehicle when in reverse gear.

Surround View Camera Displays the immediate surroundings of some or all sides of the vehicle while stopped or during low-speed maneuvers.

Active Parking Assistance Assists with steering and potentially other functions during parking maneuvers. Driver may be required to accelerate, brake, and/or select gear position. Some systems are capable of parallel and/or perpendicular parking. The driver must constantly supervise this support feature and maintain responsibility for parking.

Remote Parking Assistance Without the driver being physically present inside the vehicle, provides steering, braking, accelerating and/or gear selection while moving a vehicle into or out of a parking space. The driver must constantly supervise this support feature and maintain responsibility for parking.

Trailer Assistance Assists the driver with visual guidance while backing towards a trailer or during backing maneuvers with a trailer attached. Some systems may provide additional images while driving or backing with a trailer. Some systems may provide steering assistance during backing maneuvers.

///

RELATED CONTENT

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.

.jpg;width=70;height=70;mode=crop)