On Propulsion, Security, Sustainability and more

MAHLE sees hybrids continuing, Dodge has software to protect SRT models, Jenson Button is developing vehicles at a race track in Arizona, Audi is using green aluminum, BMW is investing in green steel, Mercedes is reducing its production emissions footprint, Bentley builds its 200,000th, and Sonata N Line impressions

#aluminum #hybrid

This is the fifth edition of on Automotive, for those of you counting (conveniently on the fingers of one hand). Five is a prime number. And at the risk of being braggadocios, there is some prime info in this one, and we don’t mean divisible by one or itself. Please let others know they can get on the list for this newsletter (for free) by going to this page. Thanks. Gary S. Vasilash

This week On Automotive

- Propulsion Systems 2035 (Not What You Think)

- Dodge Considerably Slowing Down Thieves

- Speaking of SRTs. . . The Radford Racing School

- Aluminum Made Sustainably for Audi

- Steel, Too: BMW invests in a method for CO2-free steel production

- Mercedes Makes Three

- Blast from the Past: Bentley Motors produced its 200,000th vehicle

- A Stylish Sonata

///

Propulsion Systems 2035 (Not What You Think)

MAHLE sees things getting more electrified. (Image: MAHLE)

Not All-electric. Although it might seem (and admittedly, we’ve contributed to this) that the automotive world is going all electric, not everyone agrees.

According to MAHLE Powertrain, a propulsion system engineering consultancy (its parent company is the MAHLE that makes components and systems; it had €12-billion in sales in 2019, so it is a non-trivial company), research it has conducted indicates by 2035 73% of passenger cars will still have internal combustion engines.

Data point: Jaguar is planning to be all-electric by 2025. GM has said that Cadillac will be all-electric by 2030.

More MAHLE. The firm estimates that ICEs will still be under the hoods of more than 50% of vehicles by 2040.

Bit of a twist. What is interesting to note is that MAHLE that makes powertrain components is shifting some of its production to things like e-motors and battery packs. According to Simon Reader, director of Engineering Services for MAHLE Powertrain, approximately 60% of the parent company’s light vehicle sales are “outside conventional combustion components”—and this e-mobility business is growing.

///

Dodge Considerably Slowing Down Thieves

2020 Dodge Challenger SRT Super Stock (left) and 2021 Dodge Charger SRT Hellcat (right). (Image: Stellantis)

Think about this: A Dodge Challenger SRT Super Stock, which is powered by a 6.2-liter HEMI V8 that produces 807 hp, can go from 0 to 60 in 3.25 seconds.

Now if, say, you were a thief, you might be interested in a fast getaway, so. . . .

Think again. Nowadays there is an increasing use of two-factor identification for things like signing in to a bank account or a health care system.

Dodge is bringing this to muscle cars.

Explanation from the top. Tim Kuniskis, Dodge Brand Chief Executive Officer – Stellantis: “Dodge is launching a new owner-customized ‘double verification’ security system. When flashed into the computer of affected 2015 or newer Dodge muscle cars, the protective software will limit the engine output to less than 3 horsepower, foiling fast getaways and joyrides.”

Chase on foot? The owner has a four-digit security code that must be entered into the Uconnect infotainment screen or the vehicle will produce 2.8 hp and 22 lb-ft of torque.

This would result in a 0 to 60 speed of quite a while.

Owner’s choice. This double-encryption system is owner’s choice. After all, if you have the car in your garage you might not need to deploy it.

However, when leaving it, say, overnight in a hotel parking lot. . . .

The vehicles that can get flashed at a Dodge dealer include 2015 through 2021 Dodge Challenger SRT or Charger SRT models equipped with a 392-cubic inch HEMI V8 or supercharged 6.2-liter HEMI V8 engines, as well as owners of 2019-2021 Scat Packs equipped with 392-cu.-in HEMI V8 engines.

///

Speaking of SRTs. . .

If you’re going to have an F1 champion help develop the ride, handling and performance of a vehicle, what better place to do it than a race track? (Image: Radford Racing School)

One of the premier driving schools was the Bondurant High Performance Driving School, which operated out of a facility in Chandler, Arizona.

It is the “Official High Performance Driving School of Dodge//SRT.”

New name. But it is Bondurant no more.

It is now the Radford Racing School.

Pip-pip, as it were. Radford goes to Harold Radford, who, according to the London-based company that bears his name, was “the creator of countless bespoke vehicles,” offering “customers opulent coach-built and personalized cars.”

So what does this have to do with a driving school and why might you be interested?

Because Radford as “creator of countless bespoke vehicles” is back as a builder, and it includes on its team Jenson Button, former Formula One world champion.

Track tested. The facility in Chandler includes a 1.6-mile road course and an eight-acre asphalt pad. So where better to develop a car?

Button: “For a car to be truly great, it has to feel as good as it looks. It has to possess both style and substance in equal measures, and that you can only achieve through extensive testing and improvement.

“Great engineering is only achieved through obsession over every detail and marginal gains. The testing that all Radfords will be put through is integral to creating the smiles on the faces of those that get to drive them. A race track is the perfect environment for this and it’s also my happy place of course.”

///

Aluminum Made Sustainably for Audi

Audi using sustainable aluminum for wheels. (Image: Audi)

Aluminum is light. About a third the weight of steel.

Lightweight is good for electric vehicles: the less mass to move, the further the range (or the smaller the battery).

Companies making EVs—like Audi—want to be good environmental stewards.

So aluminum can be advantageous for meeting that (less mass. . . ).

Emissions issue. But aluminum can be energy-intensive to produce. Which can lead to CO2 emissions.

But for the new Audi e-tron GT the company is offering 20-inch wheels that are made with “low-CO2 emission aluminum.”

This aluminum is made with a smelting technology developed by ELYSIS.

It doesn’t use the conventional carbon anodes used during electrolysis but “inert” anodes. They’re insoluble in the electrolyte that is part of the process.

Oxygen is released during the process instead of CO2.

ELYSIS? The company was formed as a partnership between Alcoa and Rio Tinto. It is headquartered in Montreal. The Canadian and Quebec governments invested $60-million (Canadian) in the company.

There’s another company that is financially and materially interested in this carbon-free smelting process: Apple.

It invested $13-million (Canadian).

The wheels are produced for Audi by the RONAL Group from a blend of aluminum made with the ELYSIS process and a low-carbon aluminum from Alcoa

Alcoa produces “EcoLum,” which is produced with less than 4.0 metric tons of CO2e for every ton of metal produced. This measure includes both direct and indirect emissions across the entire production chain, including bauxite mining and alumina refining.

///

Steel, Too

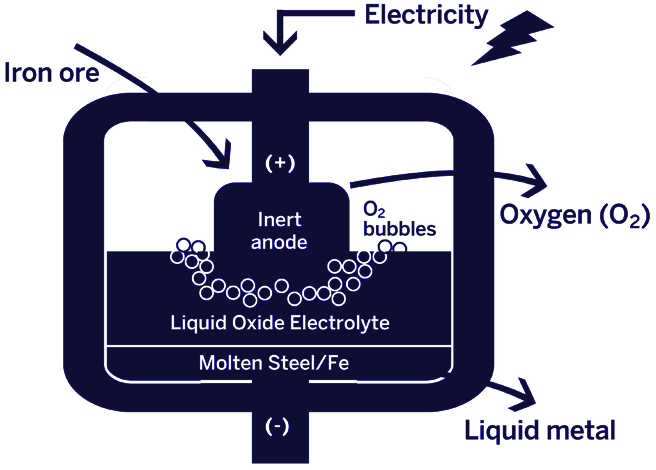

How to produce environmentally friendly steel. (Image: BMW)

“We systematically identify the raw materials and components in our supplier network with the highest CO2 emissions from production. Steel is one of them, but it is vital to car production,” said Dr. Andreas Wendt, member of the Board of Management of BMW AG responsible for Purchasing and Supplier Network.

Lots of coils. BMW uses more than 550,000 tons of steel in its European stamping plants. It has no intention to reduce its use.

But there’s a goal. Wendt: “By 2030, CO2 emissions should be about two million tonnes lower than today’s figure.”

So if steel is a big contributor to CO2 and they’re going to be reducing their carbon footprint, they need to do something.

They have. BMW i Ventures, its investment arm, is investing in a method for CO2-free steel production.

No blast. The process is called “molten oxide electrolysis.” MOE was developed by Woburn, MA-based Boston Metal. Not surprisingly, it has roots at MIT. Its development had support from organization including NASA and the American Iron and Steel Institute.

It produces molten metal without the usual blast-furnace-based process.

The chemistry. Fe2O3 + e- → 2Fe + 3/2O2

In the meantime. “We are already working with suppliers who use only green power for the steel they produce for us,” said BMW’s Wendt.

///

Mercedes Makes Three

The Class 8 eCascadia will be built at the DTNA plant in Portland. (Image: Daimler Trucks North America)

Not to leave the other German luxury marque out. . .

"The global production of Mercedes-Benz will be CO2-neutral at its own plants starting in 2022. As of next year, electricity purchased for our plants will also come exclusively from renewable sources – in other words, 100 percent green electricity worldwide. The expansion of the green power portfolio in Germany is an important basis for this", said Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG for Production and Supply Chain Management, last week.

In addition to which. . . In Germany not only will factories be powered by electricity generated by things like wind and solar voltaics, but also Daimler central and administrative facilities located in the country.

In the U.S. Daimler Trucks North America (DTNA) plans to have all of its manufacturing sites carbon-neutral by 2025.

The DTNA Portland [Oregon] Truck Manufacturing Plant became CO2 neutral in 2020. At that facility heavy-duty vocational Western Star models are built.

Electric, too. And the plant is designated for the production of the forthcoming Freightliner eCascadia and eM2, the brand’s first electric trucks.

///

Blast from the Past

Building Bentleys in the 1950s. (Image: Bentley)

This is a photo showing the production of Bentley vehicles in the 1950s, which clearly seems rather, well, non-luxury marque.

Why? Besides the historic interest that might be sated, we’re showing that because last week Bentley Motors produced its 200,000th vehicle.

The company has existed since 1919.

What were they doing the other 84 years? And more than 75% those vehicles have been produced at the company’s factory in Crewe, England—155,582 of them—since 2003.

So back in the 50s, it was comparatively slow motion.

Today the company produces 85 vehicles per day. (These are Bentleys, not Buicks, so hand-building is the rule, not the exception.)

The 200,000th? A Bentayga Hybrid. An electrified SUV. Which was built for a Chinese customer. Checks all of the boxes.

///

A Stylish Sonata

Odds are you’d never take the Sonata N Line to a track. But it really photographs well on one. (Image: Hyundai)

Even if there were more available mid-priced midsized sedans, the 2021 Hyundai Sonata would be a standout for its styling.

Yes, midsized sedans are becoming less significant in the market, but were there more vehicles with the design and amenities of the Sonata, there would probably be more shoppers looking at that segment. (Hyundai delivered 76,997 Sonatas in 2020, so it isn’t negligible.)

If you’ve got it, add to it. One of the things that the company is doing for some of its vehicles is to add a more performance-oriented version.

In this case, the N-Line.

Mechanically, it has a 2.5-liter turbo four that produces 290 hp that is mated to an eight-speed wet dual clutch transmission.

Visually it has the badges and the stitching and the sport seats and such that say “fast.”

Car and Driver says its 0 to 60 mph is 5.0 seconds.

For what is, essentially, a family sedan for a fashion-forward family, that’s enough. More than enough.

RE: Sonata N. There is a phrase about vehicle sales: “The looks get you in; the interior keeps you.” Inside, out and under the hood the Sonata N overachieves.

RELATED CONTENT

-

On Electric Pickups, Flying Taxis, and Auto Industry Transformation

Ford goes for vertical integration, DENSO and Honeywell take to the skies, how suppliers feel about their customers, how vehicle customers feel about shopping, and insights from a software exec

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

-

Choosing the Right Fasteners for Automotive

PennEngineering makes hundreds of different fasteners for the automotive industry with standard and custom products as well as automated assembly solutions. Discover how they’re used and how to select the right one. (Sponsored Content)

.jpg;width=70;height=70;mode=crop)