Partners Target Improved Powertrain Efficiency Via V2X

Development program is part of new DOE “Grand Challenge”

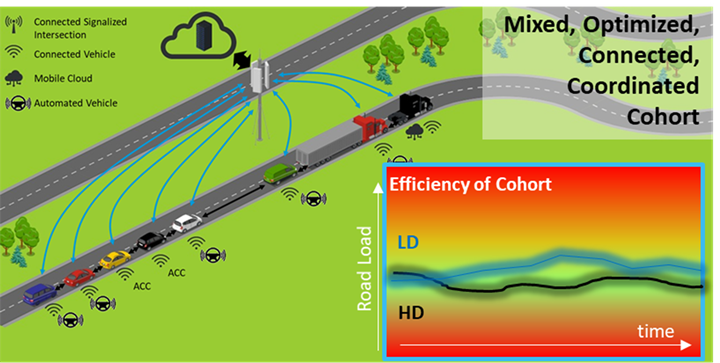

By sharing data with each other and the infrastructure, vehicles can optimize powertrain efficiency and reduce energy consumption.

Vehicle platooning (Image: Michigan Tech)

That’s the thinking behind a new joint research program that kicks off this month in Michigan. Backed by the U.S. Dept. of Energy, the 27-month project includes AVL, BorgWarner, Navistar and Traffic Technology Services along with researchers at Michigan Technological University and the American Center for Mobility.

Connected Efficiency

The program will use vehicle-to-vehicle and vehicle-to-infrastructure communications to relay information about upcoming traffic and road conditions to better coordinate and optimize vehicle speed and overall traffic flow.

Based on real-time data, route planning and predictive analysis, adjustments will be made to the operating parameters of vehicles traveling near each other to reduce their net energy consumption, according to the partners.

The study will evaluate various types of connectivity, electrification and automation. This includes platooning—where vehicles travel in a tight caravan—and smart adaptive cruise control based on surrounding traffic, upcoming turns and hills.

In addition to highways, the vehicles will be tested over arterial corridors and intersections. In some cases, information from traffic lights and other connected infrastructure will be shared.

Adaptive Propulsion

The project will include a variety of vehicles—including passenger cars and commercial trucks—and propulsion systems.

During the tests, BorgWarner will adapt its transmission, electric motors and engine control systems to optimize performance as conditions change. This includes various levels of hybridization, torque splitting, gearing, driving modes and charging states.

“We believe this joint effort will have a significant impact on energy optimization in the future,” says BorgWarner CEO Frederic Lissalde.

Big Picture

The $2 million program is funded by DOE’s Office of Energy Efficiency and Renewable Energy.

It’s one of 55 projects announced earlier this year under DOE’s Energy Storage Grand Challenge, which aims to accelerate the development, commercialization and utilization of next-generation energy storage technologies.

RELATED CONTENT

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

-

When Automated Production Turning is the Low-Cost Option

For the right parts, or families of parts, an automated CNC turning cell is simply the least expensive way to produce high-quality parts. Here’s why.

-

Mustang Changes for 2018

On Tuesday Ford unveiled—using the social media channels of actor Dwayne Johnson (this has got to unnerve some of the auto buff book editors)—the 2018 Mustang, which has undergone some modifications: under the hood (the 3.7-liter V6 is giving way to a 2.3-liter EcoBoost four, and a 10-speed automatic is available), on the dash (a 12-inch, all-digital LCD screen is available for the dashboard), at the tires (12 wheel choices), on the chassis (MagneRide damper technology is being offered with the Mustang Performance Package), and on the exterior (three new paint colors). And while on the subject of the exterior, there are some notable changes—a lower, remodeled hood, repositioned hood vents, new upper and lower front grilles, LED front lights, revised LED taillamps, new rear bumper and fascia.