Pierburg Teams with BMW on Fuel Cell Blower

Integrated system aims to boost efficiency and reduce costs

To help boost the efficiency of fuel cell systems, Pierburg is developing a recirculation blower to direct unused hydrogen back into the fuel cell stack during vehicle operation.

The company, which is part of Germany’s Rheinmetall Group, is testing the blower as part of an integrated fuel cell system being developed by BMW. The project is part of a two-year development program (FC Komp) funded by the German government.

How It Works

Driven by a brushless motor, the blower is positioned on the anode side of the fuel cell.

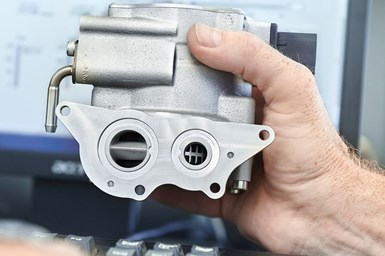

Pierburg hydrogen blower (Image: Pierburg)

Any residual hydrogen not consumed during the initial reaction process is sent back into the stack.

Pierburg is developing low- and high-voltage (800 volts) versions of the blower.

Benefits

The improved efficiency can boost the driving range of a fuel cell-powered vehicle and extend the system’s service life, according to the supplier.

By distributing the hydrogen more homogeneously in the cell, the blower also is said to enable improved cold-start response.

The FC Komp program aims to improve the efficiency and packaging of fuel cell systems, while reducing manufacturing costs, through improved integration. Other partners in the program include Germany’s Ministry of Transport, National Organization for Hydrogen and Fuel Cell Technology and the University of Siegen.

In addition to the blower, Pierburg is developing a leak-free control valve and high-voltage coolant pumps for fuel cell systems. All of the components are derived from products Pierburg supplies for conventionally powered vehicles.

RELATED CONTENT

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

-

GM Develops a New Electrical Platform

GM engineers create a better electrical architecture that can handle the ever-increasing needs of vehicle systems

-

When Automated Production Turning is the Low-Cost Option

For the right parts, or families of parts, an automated CNC turning cell is simply the least expensive way to produce high-quality parts. Here’s why.