Swiss Partners Aim to Stack the Deck on Electroactive Polymers

Production applications targeted within four years

A pair of Switzerland-based companies—Datwyler and CTSystems—have developed a new electroactive polymer (EAP) actuator technology that the companies aim to commercialize in the next three to four years for use in pumps and valves, as well as haptic feedback devices.

The partners claim their new stacked EAP architecture is more durable and consumes considerably less energy than current membrane EAPs.

CTSystems developed the design, while Datwyler will be responsible for integration and production.

How It Works

EAP elastomers can change their size or shape when stimulated by an electric field.

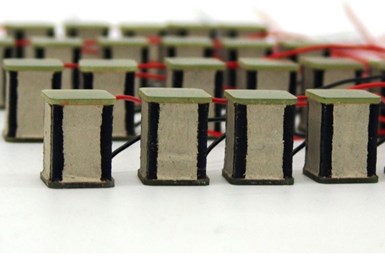

Dielectric EAP actuators (Image: Datwyler)

The technology, which dates back to 1880, typically is used for actuators and sensors. By eliminating coil components, Datwyler says, EAP-based actuators are more reliable, quieter and more efficient than conventional mechanical-based systems.

The new stacked dielectric EAP is a 3-layer system, comprised of a soft electroactive polymer sandwiched between electrodes constructed from conductive materials. The EAP is made from silicon rubber.

“When voltage is applied to the capacitor, the surface electrodes start to move towards each other, which compresses the polymer and thus allows for a small amount of axial movement,” explains Norbert Haberland, head of business development and cooperation for advanced technologies at Datwyler.

The small capacitor stack enables additional axial movement, which Haberland says allows the EAP actuator to be integrated directly into most components without the need for an additional motor or gear.

Voltage is stored in the electrodes and is applied only as needed. This differs from a coil system that requires continuous power.

In addition, the movement of an EAP-based actuator can be adjusted and controlled in a stepless manner and completely eliminates mechanical vibrations. This makes the devices well-suited for electric vehicles that don’t have baseline noise created by a standard internal combustion engine, which can mask noises generated by mechanical systems, Haberland says.

The electric systems also have fewer moving parts, which increases reliability.

RELATED CONTENT

-

Things to Know About Cam Grinding

By James Gaffney, Product Engineer, Precision Grinding and Patrick D. Redington, Manager, Precision Grinding Business Unit, Norton Company (Worcester, MA)

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.

-

Plastics: The Tortoise and the Hare

Plastic may not be in the news as much as some automotive materials these days, but its gram-by-gram assimilation could accelerate dramatically.