Cylinder Coating for Improved Performance

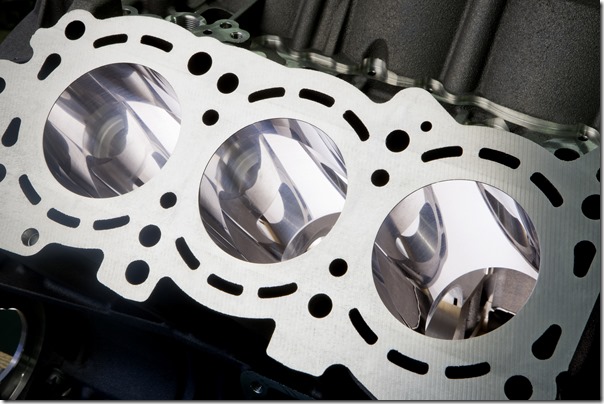

Generally, when OEMs produce aluminum engine blocks (aluminum rather than cast iron because cast iron weighs like cast iron), they insert sleeves into the piston bores—cast iron sleeves.

#aluminum

Generally, when OEMs produce aluminum engine blocks (aluminum rather than cast iron because cast iron weighs like cast iron), they insert sleeves into the piston bores—cast iron sleeves. But not all vehicle manufacturers are doing this.

Daimler, in particular, as it worked in cooperation with Heller Machine Tools to develop an arc spraying process for coating cylinder bore surfaces (and aluminum crankcases) with a process they’re calling “NANOSLIDE.”

This year the company is using it in production of approximately one-million 4- and 6-cylinder engines per year at its facilities in Untertürkheim. (And other OEMs, including Renault and Nissan—which, not coincidentally, are working with Mercedes on engines—are using the process, as well.

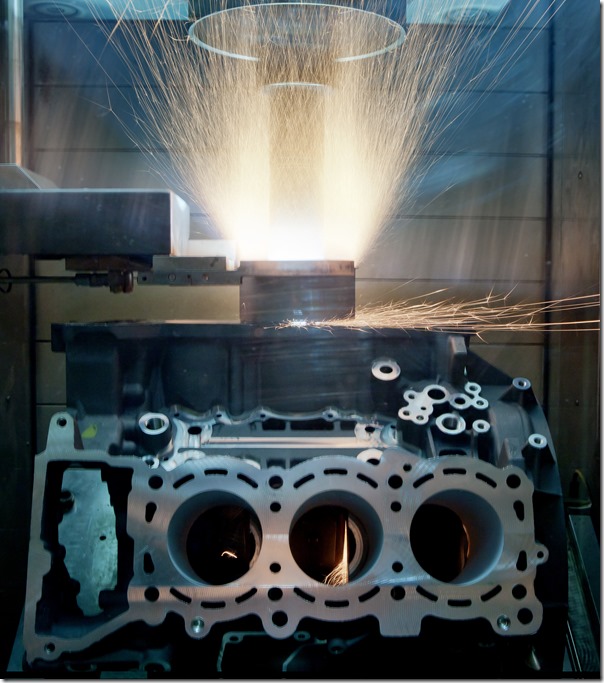

The process works by melting iron/carbon wires that are lowered into the bore and then a nitrogen gas flow propels the melted particles (which are as hot as 2000° C) at a velocity of 60 to 80 m/sec.

While the process has been long used for small volumes—Daimler has been working on the process since 1998, when it was using it for AMG engines—Heller has “productionized,” in effect, the process, which it calls “CBC,” for Cylinder Bore Coating.

This is an entire process that is performed on a Heller MC20 machining center.

Entire, as in fine boring, roughening (texturing the surface for the spray), coating, rough honing, finish honing, and finish machining. According to the company the entire process—including block load/unload—can be performed on an eight-cylinder engine within six minutes. Once the coating is applied, an optical sensor, a Jenoptik IPS 100 bore inspector, is lowered into the cylinder and provides a 360° look at the condition of the surface, including any defects or porosities.

So what does this do for an engine?

It is lighter than a liner. Given the frictional characteristics of the surface, it helps improve engine performance, which contributes to better fuel economy. It helps reduce wear in engines over time.

RELATED CONTENT

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

-

Plastics: The Tortoise and the Hare

Plastic may not be in the news as much as some automotive materials these days, but its gram-by-gram assimilation could accelerate dramatically.

-

The Koenigsegg Jesko Has An Amazing Engine

It is hard to believe that this is a vehicle in “serial” production with such extraordinary powertrain performance

.jpg;width=70;height=70;mode=crop)