Does Computer Simulation Totally Replace Physical Prototypes in Product Development?

The reports of the death of physical models are greatly exaggerated. Digital artifacts and simulation do not replace physical models in all cases.

With digitization/virtualization, and given the breadth and advances in simulation software, are physical prototypes still necessary? The quick answer is yes. While simulation hastens product development (in both design and production), expands testing capabilities, and reduces the overall time and costs in bringing a product to market, simulation is not the be-all-and-end-all. Companies still resort to physical models of digital artifacts at some point in the virtualized, simulation process. Even the simulation industry admits it: “Simulation will never replace physical prototype testing 100 percent. These are complementary tools,” says Sandeep Sovani, global director of automotive and ground transportation, for Ansys, Inc. (ansys.com), a vendor of engineering simulation software.

PHYSICS MATTERS

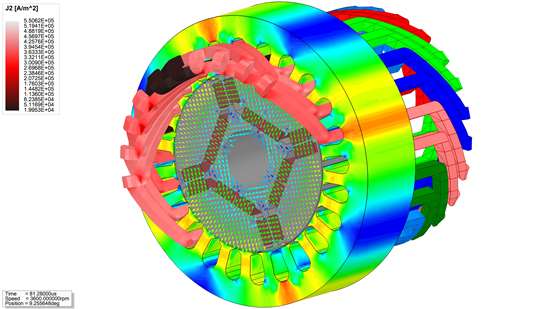

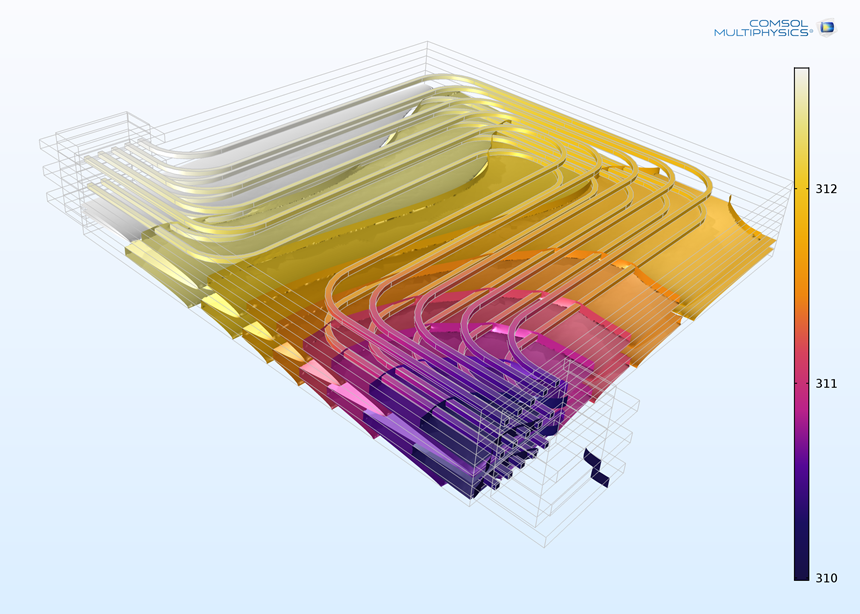

Simulation is useless if the real-world situation is unknown. “Sometimes the need comes first; sometimes the tools exist and the need comes later,” says Sovani. “As new systems come up, new simulation techniques need to be developed. Those new techniques need validation with some sort of experimentation.” Real-world experimentation. Take electric vehicles (EV) for example. Electricity and batteries are known quantities; however, EV batteries are a new component, as well as new system. Consequently, says Bjorn Sjodin, vice president, Product Management, for COMSOL, Inc. (comsol.com), software developers for multiphysics modeling, “You don’t know all the different physics phenomena that play into the game.” Because of that, product development still needs to “calibrate” the simulations—with physical models—to confirm all the physics have been defined and to ensure assumptions, models, and the concordance between physical reality and the simulations are correct.

When the Known Isn’t

Sometimes the “known” isn’t. Sjodin offers this automotive example: A “purely” mechanical design model can also include heat transfer properties that affect the capability of the mechanical design. But then, “After you’ve done heat-transfer simulations, you realize that wasn’t enough either; you need some fluid flow. Maybe that wasn’t enough; you need some electromagnetics. You can go on fiddling like this with your model until you have a high-fidelity model that matches precisely what you see in the lab.”

For complex products like vehicles, getting the virtual model’s fidelity right is “critical,” says S. Ravi Shankar, global director of product marketing, for Siemens PLM Software (plm.automation.siemens.com/global/en/products/simulation-test/), a vendor of software ranging from planning and development through manufacturing and lifecycle support. “There are a number of different attributes that engineers work on: fuel economy, energy management, drivability, strength and durability, aerodynamics, and so forth. Simulation offers an effective way to do this multi-attribute balancing. It’s much, much more difficult to do that in a meaningful way in a purely physical test environment.”

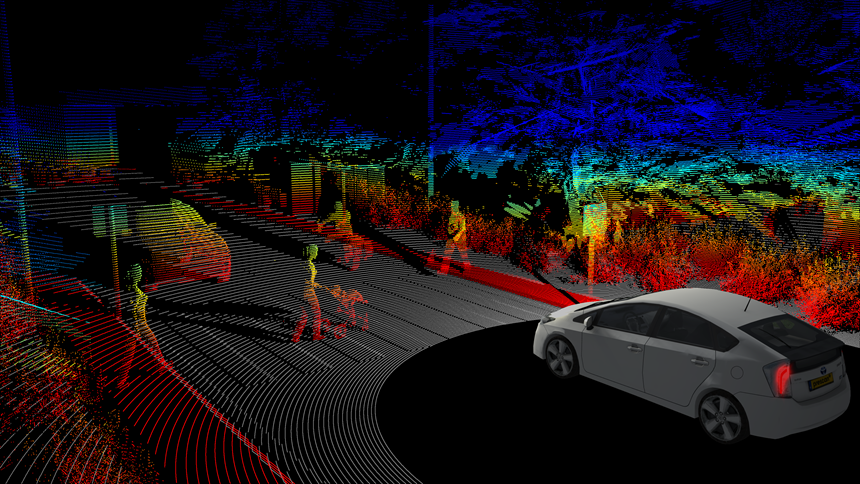

Yet physical prototypes still exist in multi-attribute environments, such as in autonomous vehicles (AV) development. “Companies need to understand the conditions under which a product needs to operate,” says Sovani. Automotive companies need the physical prototypes to collect data about how the vehicles operate in the physical world; then use that data to simulate “real life” in order to simulate an AV, actual or virtual, operating in the virtualized physical world.

SIMULATION IS A RISK-MANAGEMENT EXERCISE

“I’m a believer that the more unique the product is, the more it’s on the leading edge and you haven’t done it before, the more likely you want to create some kind of physical representation,” says David Lauzun, vice president, automotive and transportation industry, for Siemens PLM. “If you’re doing something that’s more conventional, similar to what you’ve done in the past, you’ll be more comfortable relying on a higher percentage of virtual testing.”

Sjodin agrees. “Small modifications to a virtual model, you can assume with some amount of risk, are going to match reality.” But major modifications, especially ones that stretch the virtual model beyond the last time it was calibrated with reality (read: physical model), can invalidate parts or all of the simulation, including assumptions, defined properties, and simulation algorithms. “It’s really a risk-management intricate scheme,” says Sjodin.

For example, he continues, making a dramatic design change in an existing digital model—maybe not an entire car, but a big part of it—creates a greater risk in the confidence of the model than small, perturbative changes, such as increasing a dimension one-hundredth of an inch. It’s again a question of known knowns. “Maybe there’s some new stuff going on, some unforeseen affects that you didn’t think of in the beginning. With the dramatic changes, you probably want to test their impact.” That is, test the physical model.

THE IT ANGLE

Automakers don’t really advertise how much of a vehicle design they simulate at one time. Sjodin posits they’re not simulating the entire car “down to the microscopic level in one go. That’s still too complicated.” Instead, an entire vehicle is divided into a hierarchical series of “black box” simulations, starting with very detailed component-level simulations. The results of these feed into assembly simulations, the results of which eventually feeding into system-level simulations. This is like Russian nesting dolls: Each higher-level simulation relies on the results from all the previous lower-level component and assembly simulations.

The label “full-vehicle” simulation is often a misnomer in both the physical and digitized worlds. “When you put a car model inside a wind tunnel to test its aerodynamics, it doesn’t really matter if that car has seats or an engine in it,” says Sovani. The simple representation is good enough. Similarly, to perform a “full-vehicle” aerodynamics simulation, engineers merely use the vehicle’s exterior skin as the digital model. This smaller “subsystem,” or representation, is perfectly adequate.

Sjodin sees two major obstacles to simulating an entire vehicle in one go. First, “there isn’t a computer in the world that can hold all that computational data.” Second, the simulation itself would be too cumbersome. “It’s going to be a lot of data, and you need someone to interpret all that data.” Sovani mentions a third obstacle: Assembling all the component and assembly simulations—and there are hundreds of them—into one big digital prototype, “with all their different, various aspects from different disciplines, is a systems integration challenge.”

THE PHYSICAL IS STILL PRUDENT

Another reason for the staying power of physical prototypes comes from the finished products themselves; in this case, from existing vehicles. “After it has gone into production and one wants to make some minor modifications,” says Sovani, “it might be easier to make that small change on the part or the vehicle and test it in the lab rather than set up a whole new simulation process.”

Simple mockups can range from cardboard models to 3D-printed parts to full-size models. “In the automotive industry, it’s still more prudent to do something physical to match what you’ve done virtually,” says Lauzun. “The virtual tools really are capable, and yet you still find the best way to meet your program objectives of cost, time, and quality is through the skillful combination of mixed physical-virtual testing.”

That all said, for the present, nothing beats physical prototypes when the testing involves a specific type of real-world component: people. Concludes Shankar, “You can take all the measurements you want, but ultimately, person-in-the-loop testing is sometimes quite important to verify that you are doing the right things”—and that things “feel” right.

RELATED CONTENT

-

On Fuel Cells, Battery Enclosures, and Lucid Air

A skateboard for fuel cells, building a better battery enclosure, what ADAS does, a big engine for boats, the curious case of lean production, what drivers think, and why Lucid is remarkable

-

Choosing the Right Fasteners for Automotive

PennEngineering makes hundreds of different fasteners for the automotive industry with standard and custom products as well as automated assembly solutions. Discover how they’re used and how to select the right one. (Sponsored Content)

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .