Laser Blanking Line Means Significant Material Save

Increase production and save material. Seems like a double win for the sheet metal shop.

#aluminum #robotics

Although using a laser for blanking operations is not out of the ordinary, a new approach developed by Schuler—called “Dynamic Flow Technology”—can make a significant difference when it comes to saving materials by minimizing scrap.

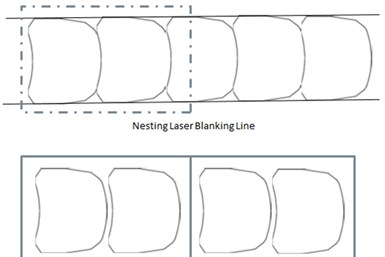

- Typical flatbed laser blanking is performed on rectangular blanks. This can result in scrap of approximately 2.4-inches per side. Also, for purposes of robotic scrap separation and stacking, there is typically a scrap grid width of 0.8 to 1.2-inches around the part.

- With that, assume a blank to produce two hoods on the flatbed laser. It would require a blank measuring 89 x 87 inches.

- The Dynamic Flow Technology (DFT) allows the hoods to be cut directly from a coil. To cut the same hoods a feed length of 81 inches and a coil width of 85 inches would be required.

- For the two hoods, the amount of scrap savings using the DFT compared to the flatbed method is approximately 11%.

Note the material savings that can be achieved by using the Dynamic Flow Technology approach vs. flatbed laser blanking. (Images: Schuler)

Schuler also says that DFT is faster than the flatbed laser, resulting in more parts per minute.

- A flatbed laser can produce three hoods per minute.

- The DFT approach can produce up to 35 hoods per minute, or some 1,700 per hour (with an overall equipment efficiency of >80%).

The Schuler line for processing parts like aluminum hoods.

RELATED CONTENT

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

-

Plastics: The Tortoise and the Hare

Plastic may not be in the news as much as some automotive materials these days, but its gram-by-gram assimilation could accelerate dramatically.

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

.jpg;width=70;height=70;mode=crop)