Can a CVT Boost EV Performance?

Bosch says new gearbox can better balance efficiency and peak output

#hybrid

Bosch is developing a continuously variable transmission (CVT) system specifically for electric vehicles, which typically use single-speed units.

How It Works

(Images: Bosch)

The aptly named CVT4EV is teamed with an inverter, electric motor and a final drive ratio tuned to the vehicle application.

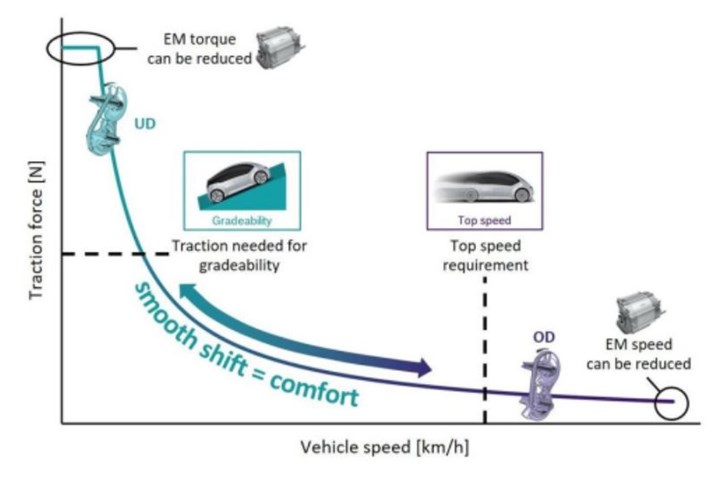

Using machine learning, the system takes into account vehicle speed, energy consumption and heat production to optimize the drive ratios of the CVT so the motor can operate at its most efficient point, according to the supplier.

What’s the Advantage?

By controlling the speed and torque of the electric motor, Bosch says the system is able to provide:

- Faster acceleration

- Higher top speeds

- Greater wheel torque for towing and off-road driving

There also are fewer torque and rpm restrictions. This enhances shift smoothness and overall NVH.

Smaller Size or Longer Range

CVT4EV’s lower torque and speed requirements can enable a smaller electric motor to be used.

Or, Bosch notes, OEMs could opt to extend driving range by using the same size motor as current EVs.

Flexibility

To further reduce costs, the scalable design can be used for various EVs, ranging from small and midsize cars to performance models and light commercial vehicle.

At the same time, the supplier says, carmakers can tune the system for multiple driving modes (uphill, off-road, normal) and brand-specific characteristics.

Dutch Connection

The CVT4EV concept was developed by Bosch’s Transmission Technology unit in the Netherlands.

What’s Next?

Bosch says it can adapt many existing components for use in the CVT4EV, and now is working with transmission companies to build prototype models.

The supplier also is in talks with multiple OEMs about the program. No commercialization timeline was provided.

RELATED CONTENT

-

When Automated Production Turning is the Low-Cost Option

For the right parts, or families of parts, an automated CNC turning cell is simply the least expensive way to produce high-quality parts. Here’s why.

-

GM Develops a New Electrical Platform

GM engineers create a better electrical architecture that can handle the ever-increasing needs of vehicle systems

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.