on VW advances, material science, projected production, Lexus ES, Audi's use of AI

On VW additive and electric. . .thousands of LEDs. . .Mercedes digital twin. . .sticking steel and polymers. . .production projections. . .EV test drive importance. . .Lexus ES review. . .Audi design and AI

A VW Additive Example

The VW ID.EXTREME. An off-road vehicle with exterior parts (those fender surrounds) made with additive. (Image: VW)

Volkswagen has a sub-brand for its ID. electric vehicle family, “GTX.”

That moniker is meant to specify models that are sporty and upscale.

Last fall VW created a concept vehicle based on the ID.4 GTX. It features dual-motor all-wheel drive (motors on both axles) that provides a system power of 220 kW (a 150-kW permanently excited synchronous motor on the rear axle and an 80-kW a synchronous motor on the front).

And to make it a more extreme version of the GTX, the engineers increased the overall system power to 285 kW.

The ID.XTREME is an off-road concept car.

Andreas Reckewerth, head of MEB Complete Vehicle (MEB is the “modular electric drive matrix” or platform that VW is using for its suite of EVs) said that the concept “convincingly demonstrates the high technical potential of the modular electric drive matrix.”

They’ve taken the donor ID.4 GTX and raised it 30 mm with rally running gear. There is closed aluminum cladding on the underside of the vehicle. One of its functions is to protect the 77-kWh battery (the company is chuffed that they have given a “second life” to the battery that is used on the original vehicle).

Additive Used

But the reason we’re calling attention to this car is. . .the wheel housing extensions that are flush with the 18-inch wheels and widen the fenders by 50 mm:

They are produced with 3D printing.

VW is big on additive manufacturing, having entered working agreements with Siemens for software and HP Inc. for hardware. The company plans to produce up to 100,000 3D printed components in its Wolfsburg facility each year by 2025.

While that is a big number, know that in a 2022 characterized by supply chain issues, chip shortages and the continuing impact of COVID, VW built some 400,000 vehicles at the Wolfsburg plant—which has a capacity on the order of 750,000 per year.

(The ID.XTREME was built in the VW Engineering facility, not a production facility. And at there is one of them, this means they additively produced four extensions.)

///

Cue the Showgirls

The orangish color on the left side of the vehicle isn’t caused by a photographer shining some light on the ID.7 but is generated by the electroluminescent paint that is used in the camouflage scheme. (Image:VW)

While on the subject of VW. . .

Somehow this seems absolutely appropriate for Las Vegas.

VW is exhibiting its forthcoming ID.7 electric sedan at CES this week.

But because this is still a vehicle-in-becoming, they have covered it with camouflage.

And the type of camo—something that actually goes back more than 100 years, to battleships in WWI—is called “dazzle.”

But VW has upped the dazzling quotient.

Bring on the Lights

As this is the 21st century, the camouflage on the ID.7 has a digital design.

Forty (40!) layers of paint are applied on the top-end sedan that will be shown in its production version (with a regular paint job) sometime during the second quarter of this year. The car, based on the modular electric drive matrix (MEB), will go into production at the VW plant in Emden, Germany, where the ID.4 is currently produced.

Some of the paint in those layers is conductive. Other layers have insulating properties.

Consequently, there are 22 areas on the vehicle that can be controlled electrically so they light up (electroluminescence).

Like less dazzling camo, the purpose is to hide the contours of the vehicle.

It is a massive QR code.

Additional Digits

While there isn’t much info:

- The wheelbase is 116.9 inches

- There is a 15-inch screen for infotainment

- The ID.7 is the sixth VW EV (ID.3, ID.4, ID.5, ID.6, ID.Buzz)

- It is the second global VW EV based on the MEB platform

///

Plenty of LEDs

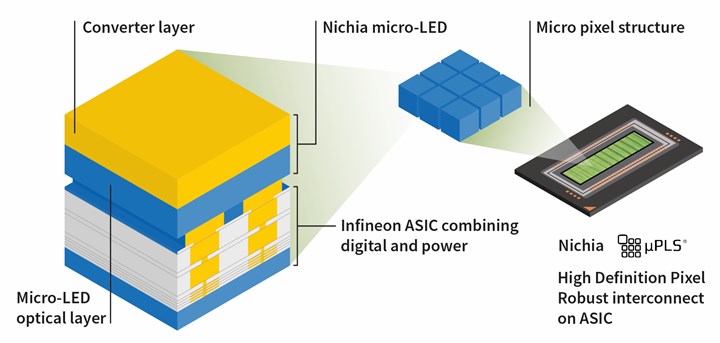

Illustration of the headlight elements. (Image: Infineon)

While on the subject of lights. . .

There are 16,384 micro-LEDs used in a headlight that was developed by Nichia Corp. and Infineon.

Nichia provides the micro-LEDs and Infineon an integrated LED driver that can drive each of the 16,384 individually.

And the benefits?

- “This solution enables a new automotive lighting experience by providing four-times wider field-of-view with significantly higher light output than any other current micro-mirror-based HD matrix-light solution. For this reason, the advanced HD light can warn drivers of hazards by highlighting people or objects on or by the side of the road. It can also project markings on the road to guide the driver through a construction site or intersection. In addition, functions such as the glare-free high beam or bending light work more precisely and smoothly compared to current adaptive driving beam solutions. This takes the driver’s road safety and driving comfort to a new level.”-- Yusuke Yamazaki, Head of Sales and Marketing Automotive, Nichia Europe GmbH

- The configuration provides a high level of energy efficiency which can result in a smaller form factor for the headlamps. This can benefit both design and manufacturing.

///

Mercedes Going Digital. . .for Factory Design

The Mercedes EQA is currently in production at Ratstatt. The digital twin of the plant will allow the new equipment for the MMA vehicles to be installed without interrupting the on-going production. (Image: Mercedes)

While a multitude of OEMs are announcing all manner of digital and electrical advances at CES (like the aforementioned VW), including Mercedes-Benz, another announcement from Mercedes and NVIDIA is worth noting:

The OEM is working with NVIDIA on a “digital-first” planning process for the production of new electric vehicles based on the Mercedes Modular Architecture (MMA) platform in its plant in Ratstatt, Germany.

The vehicles based on MMA are in the entry luxury category and will go into production in 2024 at Ratstatt.

Using the NVIDIA Omniverse 3D development platform, Mercedes is developing a digital twin of the factory that allows developers to evaluate and optimize the production operation.

The digital model is said to be both physically accurate and what is modeled operates at a rate that is synced to reality.

In addition, other Mercedes plants around the world can share the Omniverse information via the Mercedes MO360 data platform.

(Yes, Mercedes is developing software-defined vehicles that will be used the NVIDIA DRIVE Orin compute platform, in case you’re wondering.)

///

Sticking Steel and Polymer

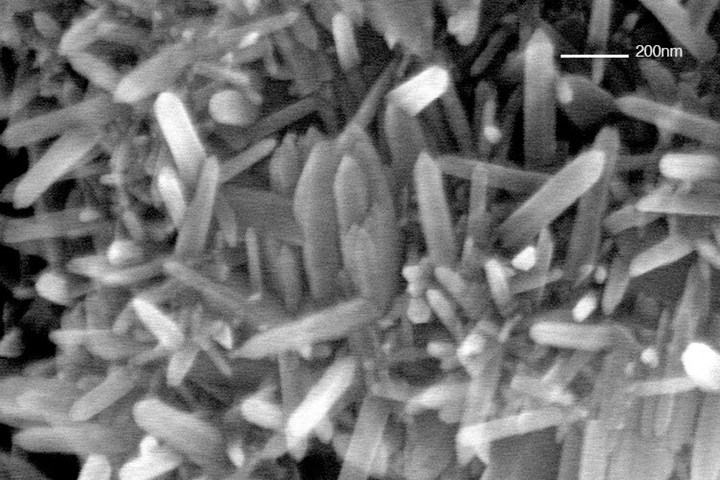

Textured surface permits the bonding of steel and polymer. (Image: The Institute of Industrial Science at The University of Tokyo)

One of the things that is well known about steel in the auto industry is that it is generally more economical than other materials. And so given the cost-sensitivity of the OEMs steel is often deployed. . .unless there are some disadvantages.

One type of steel that is widely deployed is galvanized.

But lightweighting considerations sometimes lead to a need for polymer-metal composites.

And galvanized steels don’t bond well with polymers unless there are treatments involving harsh chemicals—which may not be environmentally appropriate—and/or specialized equipment, which probably add to the cost equation.

Researchers from The Institute of Industrial Science at The University of Tokyo have developed a method to prepare galvanized steel that is inexpensive and can scale to industrial volumes.

The Process

The process involves (1) performing an acid wash of the steel, which strips away the outer layer of the zinc coating on the steel then (2) dipping the steel in hot water.

The hot water creates what are described as “rough nanoscale needle structures” on the surface.

Then using a process called “injection-molded direct joining” the polymer material surrounds the needle structure and creates strong mechanical linkage between the two materials.

Researcher Yusuke Kajihara, lead author of the paper describing the process that appears in the Journal of Manufacturing Processes, said, “Our process can be adapted for a wide range of hybrid joining applications in which metal and plastic parts need to be permanently bonded.”

Kajihara added, “Furthermore, our method does not use harsh chemicals or complicate procedures and thus is suited to the scale-up required for industrial application.”

///

Markets & Motors: Looking Ahead

13.5 million.

That’s a consistent number for the Inovev scenario for the annual size of the U.S. passenger car market going forward. Not an ideal number, but there it is. And will, apparently, continue to be (more or less—and one certainly hopes not less.)

The analyst firm posits the global car market for 2022 will be ~70 million vehicles.

That’s:

- 26.5 m China (38%)

- 13.5 m U.S. (19%)

- 11.5 m Europe (16%)

- 4.2 m Japan (6%)

- 4 m India (6%)

- 10.2 m Others (10.5%)

“Others” includes markets in Asia and South America.

Then, for 2030 the total market will grow to 79 million vehicles:

- 30 m China (38%)

- 13.5 m U.S. (16%)

- 12.5 m Europe (16%)

- 4.2 m Japan (5%)

- 6 m India (7%)

- 12.8 m Others (16%)

And in 2035 Inovev estimates the total market will be at 80 million, which is:

- 30 m China (37%)

- 13.5 m U.S. (15%)

- 11 m Europe (14%)

- 4.2 m Japan (5%)

- 7 m India (9%)

- 14.3 m Others (20%)

While the number of vehicles stays consistent in the U.S., there is a decline in share over time, albeit a small one.

Although “Others” grows, it must be kept in mind that the U.S. market is more homogeneous, whether linguistically or economically. Consequently, it is comparatively easier to sell in the U.S. market rather than one that is characterized by different languages and a wide range of earnings.

That said, it is important to recognize that other markets (including Others) are either bigger (i.e., China) or growing (e.g., India), so the influence of those markets on global offerings will undoubtedly rise.

In addition to which. . .

Internal combustion engines aren’t going to disappear for the next several years, according to an Inovev estimate.

It anticipates that globally, 67% of the engines will still be what it calls “thermal” in 2030, with the balance consisting of full EVs and plug-in hybrids.

Although the electric/electrified propulsion systems will be 60% by 2035, the 40% that are thermal could be 32 million units, based on the aforementioned global sales of 80 million passenger cars by 2035.*

However, that decline from 67% to 40% in five years is rather steep, so clearly internal combustion isn’t a good place to be.

*This doesn’t take into account that plug-in hybrids still have internal combustion engines, so there are some units there, as well.

///

The Importance of EV Test Drives

Take it for a spin—and you’re more likely to want to buy an EV, like this, the Cadilac LYRIQ. (Image: Cadillac)

Although it might be thought that those in Gen Z (born between 1997 and 2012) would be likely to forego the dealership experience when buying a new vehicle (don’t they “live” online?), according to research from CDK Global, 87% of Gen Z buyers buy at the dealership wholly or start online and finish at the dealer.

So there’s still a whole lot of interest buying from a dealer, and recent research from The Ohio State University indicates that test drives of electric vehicles—something that one might also think could be dismissed by a tech-savvy consumer—actually is beneficial to whether the EV will be bought.

Nicole Sintov, associate professor of behavior, decision making and sustainability at OSU said, “What we found is that EV test drives have a lot of potential to change how people think of themselves—and that was linked to increased intention to buy.”

Sintov and Atar Herziger, a faculty member at Technion—Israel Institute of Technology, performed two studies, one a virtual test drive and the other an actual drive.

The researchers worked to determine private meanings—what people think EV ownership would mean to one’s self-perception—and public meanings—what people think others will think about them from having an EV.

The test drives—both virtual and actual—contributed to enhancing people’s private and public senses of themselves (as early technology adopters and as car authorities).

What does this mean for those who want to move the metal (including dealers and the OEMs who are going to be producing an ever-increasing number of EVs)?

Sintov:

“If EV marketing efforts focus on saying, ‘Look at you—you have cool person status,’ that is not the route we identified. ‘How do I think about myself differently after this test drive, and in particular, how do I see myself differently in terms of being an early adopter of technology?’

“That is what makes people want to buy the car.”

///

2022 Lexus ES 250 AWD F Sport

The Lexus ES: a sedan with a gasoline engine. Yes, things like this still exist. (Image: Lexus)

An interesting thing about the current Lexus ES is that it is the seventh generation of the sedan.

Back in 1989—the year Field of Dreams was released, just to put that into context—when Lexus was launched, it did so with two vehicles, one of which was the ES 250. The other was the bigger sedan, the LS 400. (The LS still exists, as well. However, it is the LS 500 now. It is in its fifth generation.)

The RX SUV, which is widely associated with Lexus, didn’t appear until 1998.

The sedans endured, and continue to. (In fact, there is a third sedan, the IS, which was introduced in 2000.)

Contextually Low

As the roadways are increasingly covered with vehicles with high rooflines and seating positions, the ES 250 seems low, long and lean. It is 195.9 inches long and 56.9 inches high, so when you see it from side view—especially as you are used to seeing things higher and more truncated—the sleek sheet metal can be a bit of a surprise.

The seating position is much lower and as the vehicle considered here has the F SPORT trim package, the bolstered sport seats give you the sensation that you’re in something other than what could arguably be considered a family lux sedan.

That the ES 250 is powered by a 2.5-liter inline-four that produces 203 hp and 184 lb-ft of torque and is mated to an eight-speed automatic, the sportiness isn’t something that you feel off the line. Yes, there are paddle shifters, but. . .

The aforementioned IS is the sportiest of the Lexus sedans, and in model year 2021 the IS was introduced with something called the “Lexus Driving Signature.”

Yes, There Are Refined Ride & Quietness, But. . .

According to Lexus, “The ultimate goal is to deliver a new generation of Lexus vehicles that are designed with a shared brand identity that includes responsive and linear control; exceptional handling, grip and confidence; and refined ride quality and quietness.”

The ’22 ES has employed the LDS, such as having a new rear suspension brace for improved torsional rigidity and an optimized vacuum brake system master cylinder and booster for a more linear feel when getting on the binders.

Inside the ES there is a driver-centered cockpit, which Lexus calls “Seat in Control,” meaning that when you’re in the driver’s seat, all of the controls and displays are readily at hand. The center screen measures 8 inches and is a touch screen, although it can also be accessed via the Remote Touch Interface. There are Wi-Fi Connect (with an AT&T Wi-Fi hotspot), wireless Apple CarPlay and Android Auto, and if you want to go for a solid option, the Mark Levison 17-speaker audio system.

There is Lexus Safety System+ 2.5 which provides an array of tech capabilities, including pre-collision system with pedestrian detection, lane tracing assist, lane departure alert with steering assist, road sign assist, dynamic radar cruise control and intelligent high beams.

And in the End

The thing is this: the ES 250 FSPORT is a car. Which may seem obvious, but arguably is something that people are becoming increasingly disconnected from.

And more’s the pity. If you haven’t driven a car in a while, you may be surprised at how engaging the experience of driving can be.

But if you’re still one of the declining number of car considerers and are looking for a quality, luxury product that has sporty looks and amenities and wants to spend about $45K, then this is a car worth considering. Assuming the objective is to get something that isn’t a crossover.

///

This Was Not Written by ChatGPT

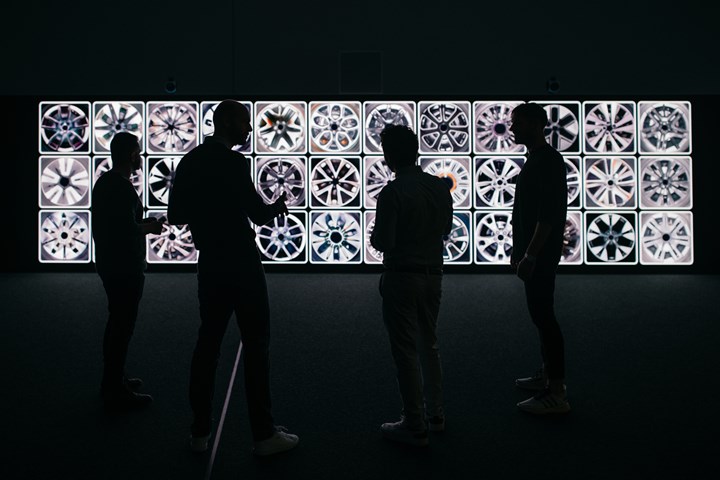

Audi designers examining an array of wheels generated by AI. (Image: Audi)

“In the modern age, data bring immense added value for companies and their employees. Audi has committed to the goal of becoming a data-driven company. To this end, we are going to use AI in many departments. So our data team is always on the lookout for new technologies.”-- Thomas Knispel, Head of Machine Learning & Data Science at Audi

Knispel made that comment in relation to the introduction of FelGAN, AI-based software developed in-house at Audi.

FelGAN is being used in the Audi Design Studio in Ingolstadt to design wheels.

The name is a combination of the German word for rim, Felge, and an acronym signifying “Generative Adversarial Networks.”

There are two algorithms. One is the generator. The other is the discriminator.

The generator makes images of rims.

The discriminator compares those images with others, including photos of actual rims.

The two algorithms go back and forth so that the generator is capable of developing images that appear (to humans, and presumably to the discriminator) “real.”

According to Audi, “Often, designers only go on to use individual elements from FelGAN’s creations, refining them into an harmonious overall design.”

For now.

RELATED CONTENT

-

On Developments at Lincoln, Magna, Fiskar, Volvo and More

Lincoln’s plans for electric; Magna and Fisker working together; Polestar in South Carolina; the Volvo XC60 driven; VW gets deep into 3D; Porsche exec on electric; BMW and hydrogen; Staubli cell for tire sensors; and Bridgestone invests in autonomous trucking company.

-

On Electric Pickups, Flying Taxis, and Auto Industry Transformation

Ford goes for vertical integration, DENSO and Honeywell take to the skies, how suppliers feel about their customers, how vehicle customers feel about shopping, and insights from a software exec

-

On Traffic Jams, Vehicle Size, Building EVs and more

From building electric vehicles—and training to do so—to considering traffic and its implication on drivers and vehicle size—there are plenty of considerations for people and their utilization of technology in the industry.

.jpg;width=70;height=70;mode=crop)