Robotic Tape System Developed

Masking tape has its genesis in the automotive body shop, back in the 1920s when an employee of 3M watched painters have difficultly removing the paper that they had affixed to vehicles to “mask” portions of the cars from the paint that was being applied.

#robotics

Masking tape has its genesis in the automotive body shop, back in the 1920s when an employee of 3M watched painters have difficultly removing the paper that they had affixed to vehicles to “mask” portions of the cars from the paint that was being applied. The idea was to create tape that would make it easier, and thus masking tape came to be developed.

The point of which is that 3M has long been involved in the auto industry. And hasn’t stopped coming up with the ways and means to improve processes.

Which brings us to a new development from 3M and Eckhart, a Warren, Michigan-based engineering company that is involved in a variety of things, ranging from autonomous guided vehicles to tooling.

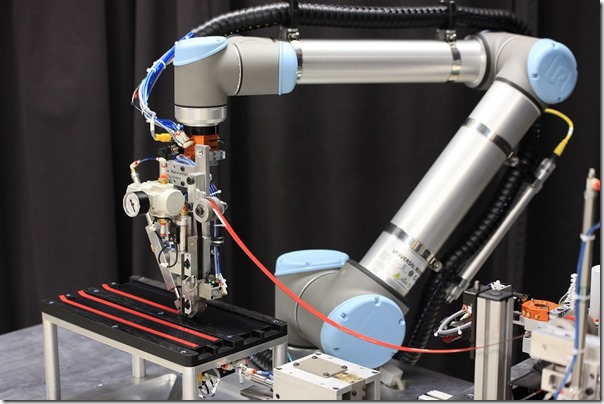

The two companies have come up with the 3M Automated Taping System (ATS), which is based on a collaborative robot and has the capability of performing tasks including supplying adhesion promoters, creating extended liner tabs, and positioning cut-to-length tape or die cuts onto components.

Explains Rachel Moses, U.S. Business Manager, 3M Automotive and Aerospace Solutions Div., “The 3M Automotive Taping system uses collaborative robot technology to optimize ergonomic safety, first-time quality, and productivity while reducing the factory footprint required to apply tape where the systems are deployed.”

Maybe its not on the masking tape scale, but it certainly could be beneficial to OEMs nonetheless.

And who knows: maybe some day just as DIYers use masking tape at home, this type of system may make its way out of the factory and into the basement. . . .

RELATED CONTENT

-

EV Tech Production Advances in China

Elon Musk was not the first CEO of Tesla; Martin Eberhard was (he was also the co-founder of Tesla, along with Marc Tarpenning). About five years after the establishment of Tesla, which occurred in 2003, Eberhard was no longer with the company.

-

On Audi's Paint Colors, the Lexus ES 250, and a Lambo Tractor

From pitching a startup idea to BMW to how ZF is developing and using ADAS tech to a review of the Lexus ES 250 AWD to special info about additive at Toyota R&D. And lots in between.

-

Cylinder Coating for Improved Performance

Generally, when OEMs produce aluminum engine blocks (aluminum rather than cast iron because cast iron weighs like cast iron), they insert sleeves into the piston bores—cast iron sleeves.

.jpg;width=70;height=70;mode=crop)