On Quantum Navigation, EVs, Auto Industry Sales and more

Sandia’s quantum navi, three things about EVs, transporting iron ore in an EV during the winter, going underwater in an EV (OK, it is a sub), state of the UK auto industry (sad), why the Big Three likes Big Vehicles, and the future of logistics.

#economics

Quantum Navigation

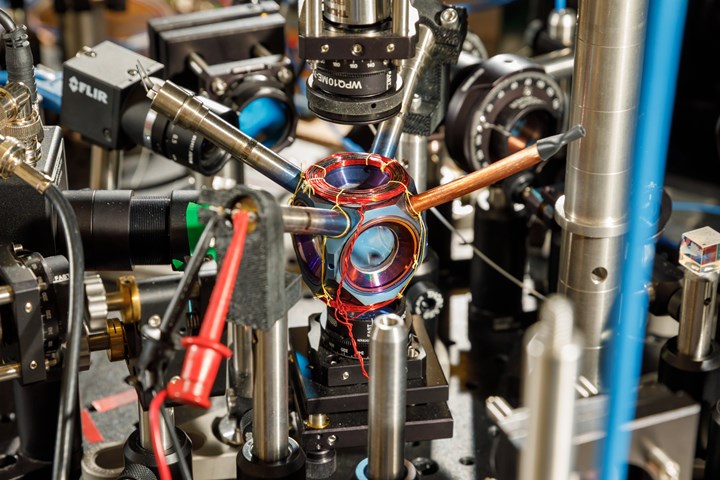

System uses quantum sensing. . .for navigation. (Image: Sandia photo by Bret Latter)

Let’s face it: sometimes your GPS system doesn’t work as well as it might because the satellites providing the location signals aren’t getting to your vehicle as they should.

Researchers at Sandia National Laboratories think they’ve got a better solution than your current navi system:

Quantum sensing

Rather than relying on satellite information, the quantum sensor would use lasers that are directed at small clouds of rubidium gas.

This provides information about rotation and acceleration, which contribute to precise navigational measurements.

Without relying on satellites.

Bethany Little, Sandia postdoc scientist:

“Quantum sensors are a growing field, and there are lots of applications you can demonstrate in the lab.

“But when you move it into the real world there are lots of problems you have to solve. Two are making the sensor compact and rugged. The physics takes place all in a cubic centimeter [0.06 cubic inches] of volume, so anything larger than that is wasted space.”

The researchers—using some materials and fabrication knowledge gained at Sandia in the development of nuclear weapons—have built a small vacuum chamber out of titanium and sapphire. This is necessary to keep gasses (e.g., helium) from getting inside the chamber.

Instead of a vacuum pump to remove any molecules that may slip in, they’ve developed devices called “getters” that use a chemical reaction to capture them without requiring outside power.

The chamber is described as being the size of an avocado.

(After all, Sandia is in Albuquerque, where guac is undoubtedly popular).

The current chamber has been in operation for about a year. The researchers want to see if it can remain sealed and operational for five years.

The are also looking at how it can be put into production.

And I think about the Garmin I bought at Costco. . .

///

Three Things About EVs

2022 Chevrolet Bolt EUV. Think of it as a representative electric vehicle image. (Image: Chevrolet)

1.

They are cheaper to repair than gas vehicles—in time.

“While EV service costs are higher than their gas counterparts early in ownership, the cumulative service costs for EVs fall over time to 31% less than gas vehicles at three years on the road—primarily due to lower maintenance costs.”

That’s James Davies, founder and CEO of We Predict, which conducted a study based on more than 13 million vehicles and 65-million service or repair orders.

The study found that in the first three months, an EV has average service costs a whopping 132% more than gas vehicles.

By 12 months, the delta is reduced, but still significant: 62% more.

But at 36 months, the EVs achieve the 31% advantage.

Why? EVs have fewer mechanical parts than gas vehicles and so there are reduced associated maintenance costs compared with gas vehicles.

(In case you’re wondering about the top five manufacturer-paid service parts in an EV in year three: (1) low-voltage battery, (2) remote keys/transmitters, (3) distance sensor, (4) high-voltage battery, (5) electric driveshaft.)

2.

The cost—in money and time—to refuel EVs is generally higher than comparable gasoline-fueled vehicles.

That’s from a study conducted by the Anderson Economic Group, “Comparison: Real World Cost of Fueling EVs and ICE Vehicles.”

The study indicates that while electric motors have better thermal efficiency than combustion engines, that is only one factor that contributes to the “real world” cost.

Other elements to be considered:

- Commercial and residential electric power/fuel costs.

- Registration taxes.

- Equipment (e.g., chargers) and installation costs.

- Deadhead miles incurred driving to a charger or refueling station.

- The cost of time spent refueling.

The researchers found that for a mid-priced ICE vehicle the cost of fueling per year, assuming 12,000 miles, is $1,030 or $8.58 per 100 miles.

For a mid-priced EV, using mostly commercial charging, the annual price for 120,000 miles would be $1,554 or $12.95 per 100 miles.

And as for time:

“For the infrastructure available as of the mid-2021 in metropolitan areas of the US, we estimate that typical time costs for EV drivers are about five to ten times that of comparable ICE drivers.”

Specifically:

For the mid-priced ICE driven by someone who earns $33 per hour, the amount of time spent over a month refueling the vehicle, an hour or less, would translate to $33 or less.

For the mid-size EV, it is estimated that using mostly commercial charging over the same period it would require seven hours which would translate into $231.

3.

Last week General Motors announced it would be working with its dealerships across the U.S. and Canada to install up to 40,000 Level 2 EV chargers. The initiative begins in 2022.

This is a good plan because consulting firm AlixPartners released results of a survey showing that 85% of likely EV buyers in the U.S. (and 86% in California) expect that automakers will ensure the availability of charging networks.

Want to know a big reason Tesla is popular?

The Supercharger network. It has some 11,000 chargers in the U.S. Of about 25,000 on the planet.

///

Baby, It’s -30 Outside

Moving iron ore powder in Sweden with a battery-electric Volvo truck. Yes, it can be done. (Image: Vattenfall)

In other EV news. . .

As winter will soon be upon us, a project conducted this past February for four weeks was announced by the participants, Volvo Trucks, ABB and Vattenfall, a Swedish energy company.

A battery electric Volvo FMX truck would drive from Junosuando to a mine in Kaunisvaara. (It is hard to describe where those places are located in Sweden. Which should give you a sense of where they are: somewhere you’re not likely to vacation in). The truck would be loaded with 15.4 tons of finely ground iron ore. Then it would go on to Pitkäjärvi, 140 km away, where the ore is unloaded.

A 280-km round trip ordinarily done with diesel trucks.

The truck was charged both when it was at the mine and when it was at the transshipment station Pitkäjärvi.

Temps in that part of the world can drop to -32° C.

As anyone who has driven an EV during the winter in balmier climes like Michigan knows, batteries don’t do particularly well in cold weather.

Obviously this project shows that the 264-kWh lithium-ion battery in the Volvo FMX could get the job done. (Otherwise we wouldn’t know about it.)

///

Dive, Dive, Drive

An EV submarine. (Image: U-Boat Werks)

That is obviously not a car, though it is an electric vehicle.

Modestly named the “Super Sub,” this submersible can dive to depths of 300 meters and allow three occupants to have a view of what’s out there through an acrylic pressure hull.

One interesting design feature is that there is a trim weight on the back of the boat that, when the pilot wants to dive, moves forward.

It features a 62-kWh lithium-ion battery pack. It powers two vertical thrusters for descending and ascending and four horizontal thrusters for forward motion.

(All thrusters are 15 kW.)

It has a top speed of 8 knots.

According to The Netherlands-based U-Boat Worx, which produces the Super Sub, 8 knots is “1-2 knots faster than the top cruising speed of a bottlenose dolphin.”

Not the sort of metric you usually encounter.

The amount of time one can spend submerged in the briny deep: 8 hours.

///

Sad September in the UK Auto Industry

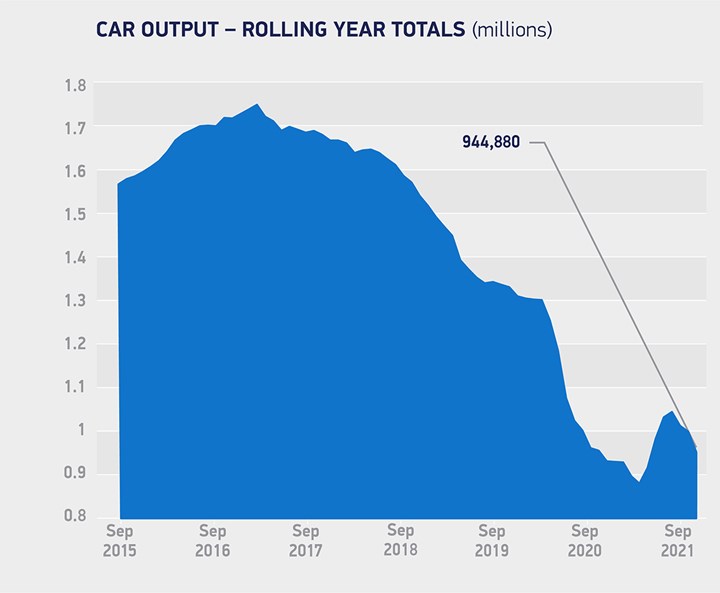

Clearly they wish it was like it was in mid-2016. (Image: SMMT)

That chart above is simply frightening.

It is from the UK’s Society of Motor Manufacturers and Traders (SMMT).

In September 2021 there were 67,169 vehicles manufactured in the UK.

Down 41.5%. The third month in a row of decline.

The worse September in UK motor manufacturing since 1982.

Part of this relates to the supply chain. An SMMT survey says that 83% of its member companies (OEMs and suppliers) say that supply chain issues—yes, including the shortage of semiconductors—have affected their business.

As in reduced orders, cost increases, logistical delays, and business disruption.

SMMT calculates that more than £2.4 billion in additional costs have been incurred due to the supply chain issues, which will probably not be recovered.

When do the UK manufacturers think the supply chain constraints will be relived? Fifty-six percent say not until the third quarter of 2022.

That chart is probably not going to improve much until that happens.

///

Still the “BIG” Three

Ford sold 534,831 F Series pickups during the first three quarters of 2021. (Image: Ford)

If you’ve ever wondered what a difference pickup trucks and large SUVs make to General Motors, Ford and Stellantis, Cox Automotive has crunched numbers for average transaction prices (ATPs) in the third quarter of 2021—which means the average amount that people actually pay at the dealership—and the numbers are unambiguous.

2021 Q3 ATPs

Ford: $51,818

GM: $50,392

Stellantis: $48,366

Then there are Honda, Hyundai and Toyota. While Toyota does have the Tundra pickup and the large Sequoia SUV, it sold 65,013 Tundras and 6,111 through the first three quarters of this year and 313,447 RAV4s and 256,769 Camrys, so it is clear that the big vehicles aren’t its bread and butter.

2021 Q3 ATPs

Honda: $34,572

Hyundai: $33,368

Toyota: $39,145

Big matters to Detroit.

///

The Future of Logistics

The future of logistics at GE Appliances. (Image: GE Appliances)

You’ve probably attended conferences (or Zoom meeting) where someone proclaims: “The future is NOW!”

Here’s a case where arguably this is the real deal, not rhetoric:

Einride—a Swedish freight tech company that produces electric, autonomous vehicles that appear like something that ought to be in the spice-harvesting scenes in Dune—and GE Appliances have established a partnership.

Einride vehicles will be deployed at GE Appliance facilities, including its 750-acre Appliance Park facility in Kentucky, as well as its operations in Tennessee and Georgia.

The deployment includes six electric trucks and one electric and autonomous pod.

According to a GE Appliances spokesperson:

“The autonomous pod will be here at Appliance Park, our largest manufacturing operation and headquarters in Louisville, Ky. The site is 750 acres and has multiple buildings where we make many of our components and parts and then move them to the larger assembly buildings. The pod will move between the production buildings – not go on public roadways.”

However, the electric trucks will be on the roadways, moving material between facilities:

“So for example, in Georgia they will move between the Appalachian Regional Port where we offload inbound materials daily to our nearby Southern Logistics Center.”

GE Appliance has invested >$1-billion over the past five year in product and new tech for its U.S. production and distribution operations.

As Bill Good, vp of Manufacturing at the company, put it:

“Sustainability and cost-efficiency is a prerequisite for implementing innovation into our business strategy. The partnership and technology investment with Einride is allowing us to deploy safer, more sustainable, and cost-effective solutions for the movement and transportation of material.”

And it can undoubtedly help ensure its future.

RELATED CONTENT

-

On Lincoln-Shinola, Euro EV Sales, Engineered Carbon, and more

On a Lincoln-Shinola concept, Euro EV sales, engineered carbon for fuel cells, a thermal sensor for ADAS, battery analytics, and measuring vehicle performance in use with big data

-

Ford’s $42 Billion Cash Cow

F-Series pickups generate about 30% of the carmaker’s revenue. The tally is about twice as much as what McDonald’s pulls in.

-

On The German Auto Industry

A look at several things that are going on in the German auto industry—from new vehicles to stamping to building electric vehicles.

.jpg;width=70;height=70;mode=crop)