On Urban Transport, the Jeep Grand Wagoneer, Lamborghini and more

Why electric pods may be the future of urban transport, the amazing Jeep Grand Wagoneer, Lamborghini is a green pioneer, LMC on capacity utilization, an aluminum study gives the nod to. . .aluminum, and why McLaren is working with TUMI.

#economics

This week On Automotive

- Clever Urban Transport Approach

- 2022 Jeep Grand Wagoneer: Sui generis

- Lambo Pursues Carbon Neutrality

- Capacity Utilization Projection

- Aluminum BIW Advantage

- What You Need to Travel in Your McLaren

///

Clever Urban Transport Approach

Not only do those pods ride on the elevated track, but they can descend to the roadway, as well. (Image: Urban.MASS)

For a few years, light rail was the rage in cities. There are lots of people that need to be moved in urban centers, and trains are certainly a means of mass transit.

But according to Urban.MASS, a UK startup, they have developed a superior alternative:

Driverless, electric pods

The capsule-shaped pods have electric hub motors driving each of its rubber-wrapped wheels. Each pod, as presently designed, can accommodate 16 people, 12 sitting and four standing.

The pods can travel on the road but generally on the elevated “Duo Rail” track.

When on the road, the people from Urban.MASS tell us, there are steering actuators that allow a pod to maneuver as required, as well as a regenerative braking system.

The word from the company is that the system “relies on well-proven automotive industry components for its performance--avoiding magnetic levitation, air cushions, or evacuated tubes, etc.”

According to Urban.MASS the Duo Rail track—powered by overhead solar canopies in some instances—come in prefabricated sections so they can be quickly installed.

The company claims an estimated cost save of 50% compared with light rail.

Here’s the interesting bit

“floc” technology.

A light rail system has a series of connected vehicles on a track.

Each car goes to the same place. One after the other. Every time.

In the Urban.MASS setup, each of the pods operates individually.

There are ramps that are part of the track system.

This means that a pod can join a series of other pods on the track (“flock” with them) or split off to take the passenger to a specific site, not just a station along the track route.

In some cases, there is a train of pods. In other cases, not.

Bonus capability

While transporting people in increasingly crowded and grid-lock urban centers is a key objective of the floc tech, there is another use for the system: logistics.

“The floc system can be used for parcel deliveries between logistics centres, ports and airports during off-peak times via special purpose-built Pods design just for cargo deliveries, as the system uses battery technology and rubber tyres the operation is quiet and non-polluting.”

(Yes, UK spelling because, well, that’s where the answers to our questions came from.)

///

2022 Jeep Grand Wagoneer: Sui generis

Some vehicles have presence. The Grand Wagoneer has that and more. (Image: Jeep)

The word “icon” gets bandied about quite a bit nowadays. Presumably to add some cred to vehicles.

And the folks at Jeep use it to describe the Grand Wagoneer (and the still-grand-but-not-as-much version, the Wagoneer).

As in: “We are ready to start a new exciting adventure with a model that wrote some of the most iconic pages in the history of the American automobile.”

That’s Christian Meunier, Jeep Brand Chief Executive Officer.

As for the history, the Wagoneer was first launched in 1962. According to Jeep “It was the first SUV that matched four-wheel-drive capability with better ride quality, a stylish appearance and luxurious interior.”

The Grand Wagoneer appeared in 1984 “and marked the beginning of the luxury SUV.”

Heritage, if you’ve got it, is good.

But people buy vehicles now.

Yes, the Grand Wagoneer may be an icon.

When I encountered it up close in the real world, I was shocked.

In a good way.

Forget the icon. This is a vehicle that is striking right now.

What it is.

This is an impressive, imposing, well-designed object that has to be seen to truly understand what the Jeep team has accomplished.

It just isn’t because it is big—and it is big: 214.7 inches long, 75.6 inches high, 94 inches wide. I was glad there was a powered running board that assisted in ingress and egress as the ground clearance with the air suspension system is 10 inches.

No, what makes this out of the ordinary is that there is a danger when designing large passenger vehicles that the large expanses of sheet metal can seem like painted slabs lacking character and charm.

Somehow Mark Allen and his team at Jeep Design have managed to pull off a look that characterizes what is often called (but rarely achieved) “classic American luxury.”

Restrained. Confident.

Room to go.

And once in the cabin—and you feel that it could be a bona-fide cabin in a place like Jackson Hole, given the spaciousness (206.6 cubic feet in there) as well as the quality of wood, leather and metal—again you get the sense of a space that doesn’t try to be something that it isn’t.

Yes there is technology—there is as much as 75 inches of digital screen area in the vehicle. And there are Uconnect 5 and 4G LTE Wi-Fi for up to eight devices and wireless Apple Car Play and Android Auto and on and on it goes.

But it seems like a living room more than the flight deck of a NetJet.

There is also operational tech, like active driving assist, night vision, intersection collision assist (four radar sensors and a camera for that one), and more.

Oh, and it is a Jeep, which means 4x4 systems that allow confident driving even in places where you’re not typically likely to drive (unless, of course, you live someplace like Jackson Hole and don’t much like roads).

There is power from a 471-hp 6.4-liter V8.

Go see it. Sit in it. Drive it.

It is something with resonance.

And quite possibly authentically iconic.

///

Lambo Pursues Carbon Neutrality

The Lambo Sián goes fast. And Lamborghini is going green. (Image: Lamborghini)

When General Motors announces, as it did a few weeks ago, that it plans to power its U.S. sites with 100% renewable energy by 2025—five years earlier than it had previously announced, and 25 years earlier than the target it had set for itself in 2016—we nod and figure that that is something that GM would do.

But this from Stephan Winkelmann, chairman and CEO of Automobili Lamborghini, comes as something of a surprise:

“In the area of sustainability, Lamborghini was a trailblazer in the automotive industry, at a time when the issue was not yet being addressed by large companies, or only partially. Our commitment started in 2009 through a series of programs and investments, which in 2015 led us to achieve ‘CO2-neutral’ certification for the entire facility [the Sant’Agata Bolognese production plant]. And today, our path is accelerating with the goal of going from a CO2-neutral production site to a CO2-neutral company through a holistic approach involving the product, factory, logistics, and supply chain.”

In addition to switching to biomethane to power the plant, the company has created a park with 10,000 oak trees, is running a bee monitoring program and more.

Admit it: The last thing you think about when you see a Lambo Sián is how “green” it is.

But it is encouraging to know that ever supercar producers take the climate seriously.

///

Capacity Utilization Projection

Companies want to use their assets to the utmost. Factories, for example.

The metric that measures how well the assets are being used is the capacity utilization rate.

While the chip shortage has thrown a shoe in the works of factories in North America (as well as elsewhere in the world), the economists, analysts and forecasters at LMC Automotive think that things are going to be improving.

Improvement toward the latter part of 2022.

Bill Rinna, LMC director, Americas Vehicle Forecasts, has run some number on what capacity utilization will be in the U.S. for the OEMs in 2025.

Know that the higher the number the better. (Although 100 probably wouldn’t be ideal because there is a need for some flexibility and headroom to accommodate changes.)

Here’s what LMC expects.

2025 Plant Capacity Utilization

- General Motors: 68%

- Ford: 76%

- Toyota: 91%

- Stellantis: 76%

- Honda: 96%

- Nissan: 59%

- Daimler: 71%

- Hyundai-Kia: 81%

- Tesla: 39%

- Volkswagen: 55%

- BMW: 71%

- Subaru: 87%

- Other (start-ups): 53%

- Industry Average: 72%

Why does this matter?

Imagine you’re attached to a facility where there is low capacity utilization. Maybe a plant where there are just a couple of vehicles being built that are so-so in sales.

Clearly an asset that isn’t providing the sort of return that an OEM needs.

As Rinna puts it, “some consolidation may be in order.”

You know what that means.

///

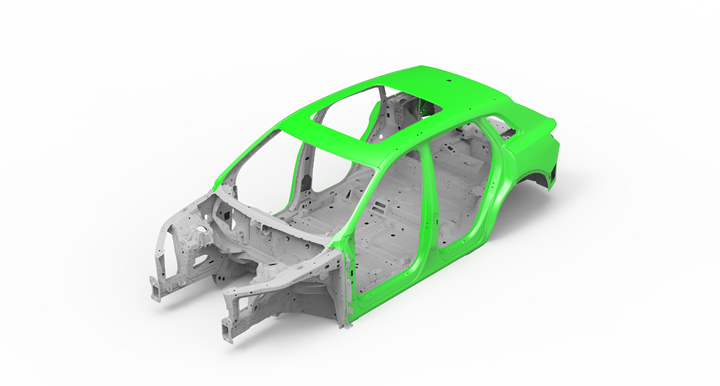

Aluminum BIW Advantage

Putting on a top hat—an aluminum top hat. (Image: Alumobility)

First, a disclosure:

Alumobility is self-described as “a non-profit organization focused on technical studies to advance the adoption of aluminum automotive body sheet.” It was founded in 2021 by Constellium and Novelis, both companies that make that non-ferrous material. (Other members have subsequently joined.)

That out of the way. . . .

Alumobility studied the top hat (or upper structure) of the current Audi e-tron BEV SUV.

The research found that by using aluminum rather than the existing advanced high strength steels and ultra-high strength steels that are on the e-tron there is a 42% weight savings.

Mass reduction is probably more important to BEVs than ICEVs (internal combustion engine vehicles) because of the range limits imposed by batteries.

The study also found that the aluminum top hat requires fewer components and joints than the steel structure. That means a reduction in time and cost of assembly.

Fine print

To add some granularity:

The parts in question are the roof, roof rail and A-pillar upper assembly; body side outer; A-pillar lower assembly; B-pillar assembly; C/D-pillar assembly; rocker assembly; lower back assembly.

- The total steel part count, weight and joint count are: 137 parts, 193.8 kg and 3,217 joints.

- The total aluminum part count, weight and joint count are 133 parts, 113.2 kg and 2,556 joints.

///

What You Need to Travel in Your McLaren

Think about it as a carry-on when driving a McLaren. (Image: McLaren)

Let’s say. . . you have a McLaren 720S Spyder.

710 hp. 0 to 60 mph in 2.8 seconds. Maximum speed: 212 mph.

It is a masterpiece of carbon fiber construction (with aluminum front and rear crash structures).

And then let’s say. . . you want to go on vacation.

Which means baggage. The front luggage capacity is 150 liters. Or 5.29 cubic feet. In back it is 58 liters. Or 2 cubic feet.

Not a whole lot of room.

So TUMI and McLaren have collaborated on luggage.

Like the Halo backpack that can accommodate a 14-inch laptop.

And the Brox Slim Utility Pouch “perfect for those who prefer to carry only the essentials.”

Somehow those who buy a car with a $315,000 MSRP are likely to want more than just “the essentials.”

But if you’re going to travel in that 720S, essentials are the max.

RELATED CONTENT

-

On Fuel Cells, Battery Enclosures, and Lucid Air

A skateboard for fuel cells, building a better battery enclosure, what ADAS does, a big engine for boats, the curious case of lean production, what drivers think, and why Lucid is remarkable

-

Choosing the Right Fasteners for Automotive

PennEngineering makes hundreds of different fasteners for the automotive industry with standard and custom products as well as automated assembly solutions. Discover how they’re used and how to select the right one. (Sponsored Content)

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.